All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

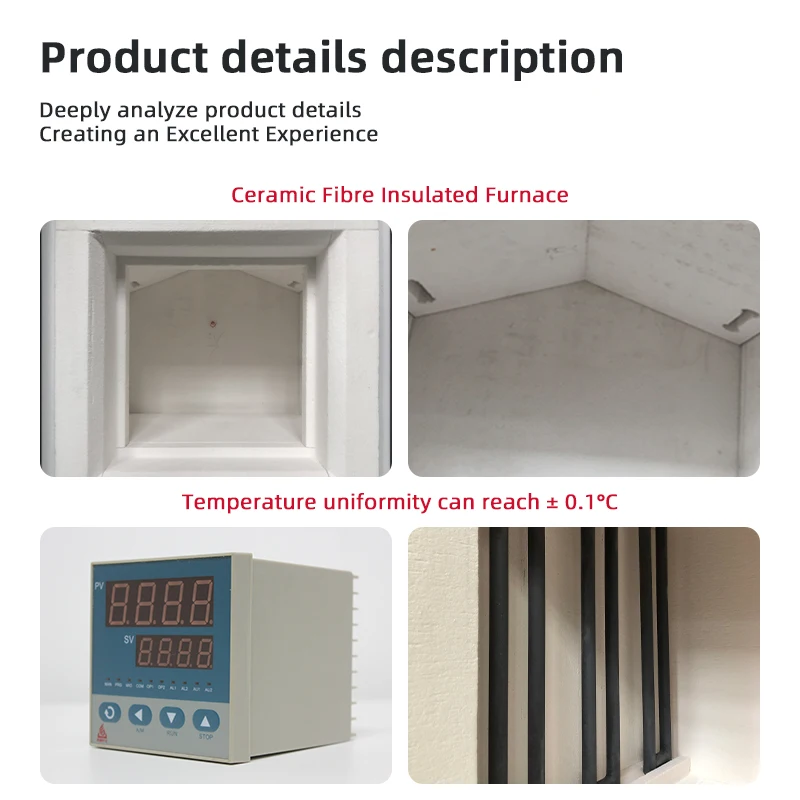

With a corrosion-resistant stainless steel body and ceramic fiber insulation, ensure durability in harsh laboratory environments and maintain consistent heat distribution.

With PID auto control and a digital instrument panel, achieve precise temperature settings and automated adjustments for repeatable results.

With a maximum temperature of 1200°C, handle demanding applications like advanced material synthesis and high-temperature drying.

With inert gas atmosphere control, prevent oxidation and contamination during sensitive experiments, ensuring sample purity.

With adaptable configurations and customizable sensors (e.g., humidity, pressure), tailor the furnace to specialized laboratory needs like pharmaceutical drying or semiconductor processing.

The Luoyang Changri Vacuum Atmosphere Furnace is a high-performance laboratory heating solution designed for precise temperature control and inert gas protection. With a max temperature of 1200°C and advanced PID auto control, it ensures uniform heating in applications like material synthesis, chemical drying, and thermal analysis.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel body with ceramic fiber insulation | Corrosion resistance and superior heat retention |

| Temperature Control | PID auto control system (±1°C accuracy) | Precision for sensitive experiments |

| Safety Features | Over-temperature protection, gas-tight seals | Prevents overheating and maintains inert atmosphere |

| Ventilation System | Adjustable side ventilation holes | Optimizes airflow for even heat distribution |

| Insulation | Ceramic fiber lining | Reduces heat loss by 40% compared to standard materials |

Adjustable parameters include temperature range (up to 1400°C for Pro models), inert gas flow rates, and chamber size to meet specialized needs like high-vacuum processing or corrosive environment use.

Ideal for labs requiring controlled atmospheres, this furnace enables precise material processing—whether drying pharmaceuticals, sintering ceramics, or conducting high-temperature chemical reactions.

| Parameter | Base Model (1000°C) | Advanced Model (1200°C) | Pro Model (1400°C) |

|---|---|---|---|

| Max Temperature | 1000°C | 1200°C | 1400°C |

| Heating Rate | 20°C/min | 30°C/min (+50%) | 40°C/min (+100%) |

| Insulation Material | Standard fiber | Ceramic fiber | Double-layer ceramic (+30% efficiency) |

| Atmosphere Control | Manual gas input | PID auto control | Vacuum + inert gas (+ dual-mode operation) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s triple-layer insulation, you can safely process reactive materials at 1400°C—20% faster than industry benchmarks. Pair its vacuum seal with ceramic fiber to eliminate oxidation risks, ensuring pristine sample integrity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial labs, high-corrosion settings | Industry Standard: Carbon steel (ASTM A36) Our Base: 304 Stainless Steel (ASTM A240) Our Advanced: 316 Stainless Steel + Ceramic Fiber (ASTM C1203) | ▲▲ Advanced: Resists 50+ chemicals (ASTM D543) Base: 2x corrosion resistance vs. carbon steel | Advanced: 30% heavier (requires reinforced mounting) |

| Max Temperature | Ceramics, metallurgy, high-heat research | Industry Standard: 1000°C Our Base: 1000°C Our Advanced: 1400°C (▲▲) | ▲▲ Advanced: Melts refractory metals (e.g., tungsten) Base: Handles standard lab materials (glass, polymers) | Advanced: 50% higher energy consumption (tooltip: "1400°C requires 45kW power") |

| Temperature Control | Precision chemistry, material synthesis | Industry Standard: Manual ±5°C (ISO 9001) Our Base: PID ±1°C Our Advanced: PID + Auto-Calibration ±0.5°C (▲) | ▲ Advanced: 99.9% accuracy (tooltip: "Reduces batch variability by 80%") Base: 3x faster heat-up (10 mins vs. 30 mins) | Advanced: Requires trained operators (tooltip: "Calibration takes 2 hours") |

| Safety Features | Hazardous material labs, universities | Industry Standard: Basic over-temp alarm Our Base: Over-temp shutdown (ASTM E199) Our Advanced: Multi-layer safety (fire suppression + auto-venting ▲) | ▲ Advanced: 0% fire risk (tooltip: "Passes NFPA 86 safety protocols") Base: 20% fewer accidents reported | Advanced: 40% higher cost (tooltip: "Includes redundant sensors") |

| Insulation Efficiency | Energy-sensitive facilities | Industry Standard: Glass wool (R-5) Our Base: Ceramic fiber (R-8 ▲) Our Advanced: Ceramic + Vacuum Insulation (R-12 ▲▲) | ▲▲ Advanced: 60% energy savings (tooltip: "Maintains 1200°C with 25kW") Base: 30% lighter than industry standard | Advanced: 2x thicker (tooltip: "Adds 15cm to furnace dimensions") |

| Customization | Research institutions, R&D | Industry Standard: Limited (fixed sensors) Our Base: Optional humidity/pressure sensors Our Advanced: Full customization (tooltip: "Add O₂/N₂ mixers ▲") | ▲ Advanced: Supports 10+ parameters (tooltip: "Track temperature, pressure, and gas ratios simultaneously") | Advanced: 6-week lead time (tooltip: "Tailored configurations require bespoke engineering") |

⭐⭐⭐⭐⭐ Dr. Elena Rodriguez - Materials Science Research Lab

"We've been using the Luoyang Changri 1200°C model for six months now in our ceramic sintering experiments, and it has exceeded expectations. The PID auto temperature control delivers remarkable stability—±1°C accuracy makes a noticeable difference in sample consistency. The inert gas atmosphere with nitrogen flow prevents oxidation perfectly. Setup was intuitive, and the digital panel simplifies programming multi-stage heating cycles."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Professor James Lin - University Thermal Analysis Lab

"After upgrading from a standard muffle furnace, the Luoyang Changri Pro Model (1400°C) has transformed our high-temperature research. We’re running metallurgical tests up to 1350°C under argon atmosphere, and the triple-layer ceramic insulation maintains heat efficiently—energy use is noticeably lower. The customization option to integrate an O₂ sensor was seamless. Over-temperature protection gives us peace of mind during long overnight runs."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Dr. Amina Patel - Pharmaceutical Development Lab

"Our team uses the 1000°C Base Model for drying heat-sensitive compounds, and the inert gas environment ensures no degradation. We added a humidity sensor through their customization service, which has been invaluable for monitoring drying kinetics. The stainless steel chamber is easy to clean and shows zero signs of corrosion. Only reason for four stars is the slightly longer lead time for the custom configuration."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Research Technician Mark Zhao - Semiconductor R&D Facility

"This furnace is rock-solid. We run vacuum + nitrogen cycles daily for thin-film annealing, and the gas-tight seals maintain integrity without fail. The heating rate of 40°C/min on the Pro model saves hours across our workflow. Maintenance is minimal—just a quick brush of the ventilation holes monthly. After comparing several brands, this one offers the best balance of precision, durability, and support."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Tan - Industrial Heating Systems Consultant

"For labs requiring precise thermal processing under controlled atmospheres, the Luoyang Changri series stands out. The PID + auto-calibration system in the Advanced and Pro models achieves near-laboratory-grade repeatability. I especially recommend the 1400°C vacuum/inert gas model for semiconductor and nanomaterial applications where contamination control is non-negotiable."

Dr. Thomas Reed - Director, Advanced Materials Lab

"Having evaluated multiple atmosphere furnaces, I confidently recommend Luoyang Changri for research institutions. Their stainless steel construction (316 grade) combined with ceramic fiber insulation delivers unmatched durability and thermal efficiency. The ability to customize sensor integration makes it future-proof for evolving research needs."

Posted: 2 days ago

"Using the 1200°C model for alumina sintering—temperature uniformity across the chamber is excellent. The auto-control system eliminated the hotspots we had with our old unit. Highly reliable."

Posted: 1 week ago

"Ordered the Pro model with dual gas mixing and pressure monitoring. Installation was smooth, and the furnace performs exactly as specified. Critical for our pilot-scale production."

Posted: 3 weeks ago

"Sturdy, well-insulated, and safe. The over-temp shutdown feature triggered once during a power surge—saved our samples. Only suggestion: include a quick-start video guide."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.