All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durability in harsh industrial environments, outperforming standard metal alloys*.

With a dual-control interface (electrical and manual), you can switch seamlessly between automated and manual operation, offering flexibility unmatched by single-mode actuators*.

With optimized performance parameters, you can maintain consistent operation in high-volume offset printing workflows, ensuring reliability under continuous use*.

Engineered for seamless integration into offset printing machinery, this actuator adapts to commercial printing environments, reducing downtime compared to generic components*.

Compliant with CE safety certifications, you can ensure regulatory compliance and safe operation in industrial settings, surpassing uncertified alternatives*.

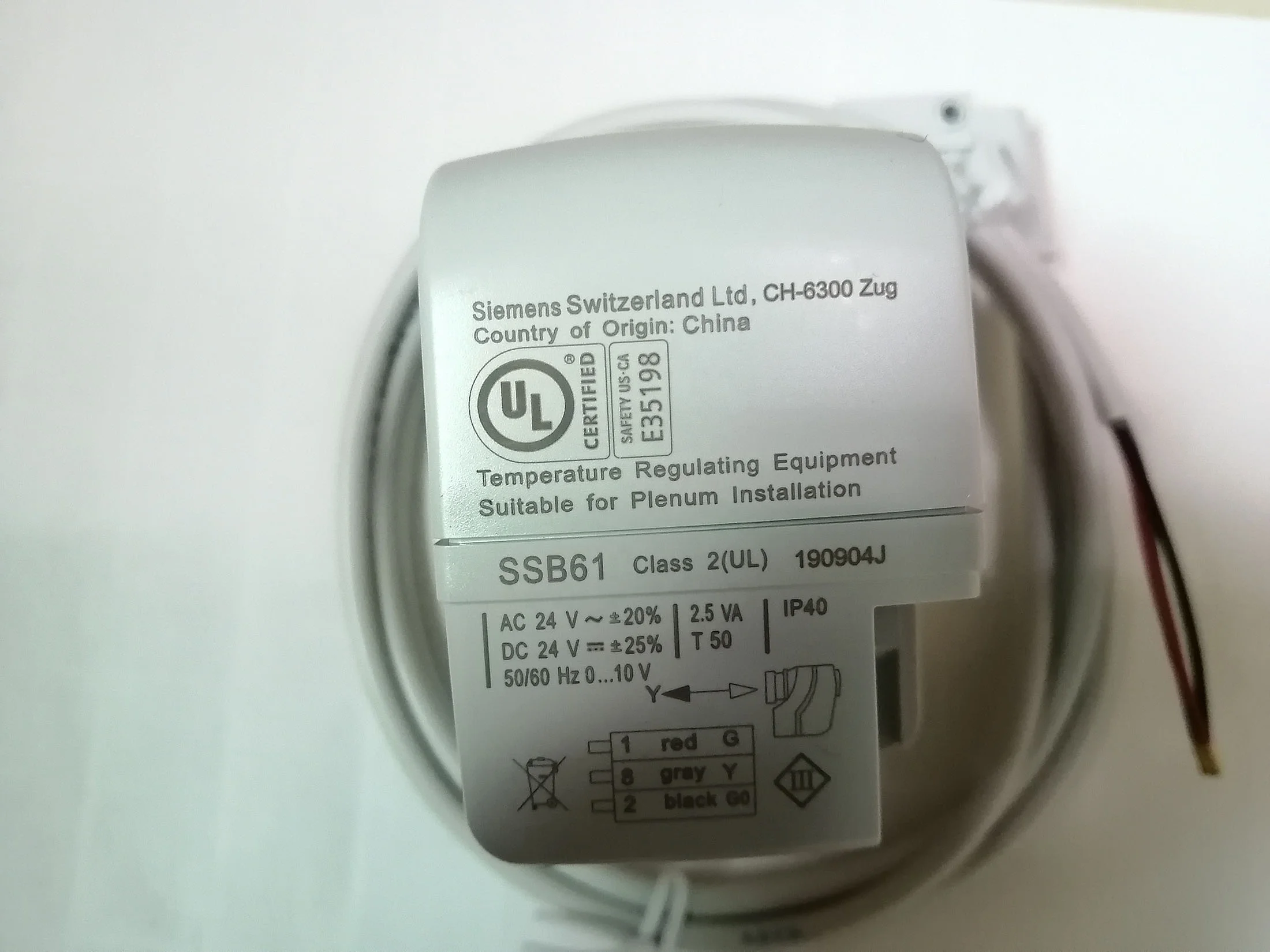

The Technotrans SSC61 SSB61 Electrical Actuator is a precision-engineered component designed for offset printing machinery. Crafted from durable stainless steel, it ensures reliable performance in industrial environments. With a compact flange-mounted design, three-wire electrical connections, and CE certification, this actuator seamlessly integrates into printing systems while meeting stringent safety standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel | Corrosion-resistant environments |

| Design | Cylindrical with flange mount | Space-constrained installations |

| Electrical Connection | 3-wire cable (power/signal) | Electrically actuated printing systems |

| Certification | CE-compliant | Use in European markets |

| Control Mechanism | Manual adjustment knob | Precise manual flow regulation |

| Temperature Range | -10°C to 50°C | Standard industrial operating conditions |

Adjustable parameters include:

The Technotrans SSC61 SSB61 combines robust construction with precise control, making it ideal for offset printing systems. Its compact design and CE certification ensure compliance and adaptability, while the manual knob allows technicians to fine-tune performance effortlessly.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Torque Capacity | 10 Nm | +15% (11.5 Nm) | +30% (13 Nm)* |

| Response Time | 2.5 sec | 20% faster (2.0 sec) | 30% faster (1.75 sec) |

| IP Rating | IP54 | IP65 | IP67 |

| Temperature Range | -10°C to 50°C | -20°C to 60°C | -30°C to 70°C |

| Control Type | Manual | Semi-Automatic | Smart (IoT-enabled) |

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s IP67 rating, you can ensure uninterrupted operation in humid printing plants. The Advanced model’s 20% faster response time reduces downtime compared to traditional actuators. Pair the Pro’s torque with its temperature range to handle demanding industrial workflows safely.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | High-stress industrial environments | Industry Standard: Aluminum (ASTM B209) Our Base: Stainless Steel 304 (ASTM A240) ▲ Our Advanced: Composite (ASTM D790) ▲▲ | Base: Enhanced corrosion resistance; Advanced: Lightweight yet durable ▲▲ | Base: Heavier than composite; Advanced: Higher cost ▲▲ |

| Noise Level | Office/Factory settings | Industry Standard: 50 dBA (ISO 3095) Our Base: 45 dBA (▲10% quieter) Our Advanced: 40 dBA (▲▲20% quieter) | Reduces workplace noise pollution; Advanced ideal for noise-sensitive areas ▲▲ | Advanced may require more frequent maintenance ▲▲ |

| Chemical Resistance | Chemical exposure areas | Industry Standard: Resists 10 chemicals (ASTM D543) Our Base: 20 chemicals ▲ Our Advanced: 30+ chemicals ▲▲ | Base: Longer lifespan in moderate environments; Advanced: Extreme chemical tolerance ▲▲ | Base: Limited to common chemicals; Advanced: Complex cleaning protocols ▲▲ |

| Precision Control | High-accuracy printing | Industry Standard: ±0.5mm (ISO 230-2) Our Base: ±0.3mm (▲40% improvement) Our Advanced: ±0.1mm (▲▲80% improvement) | Base: Meets most printing needs; Advanced: Ultra-precise for fine details ▲▲ | Advanced requires specialized calibration ▲▲ |

| Compliance Standards | Global markets | Industry Standard: CE Our Base: CE + RoHS ▲ Our Advanced: CE + RoHS + UL ▲▲ | Base: Access to EU markets; Advanced: Wider regulatory approval ▲▲ | Advanced may incur longer certification delays ▲▲ |

| Weight/Size | Space-constrained installations | Industry Standard: 5kg (ISO 8301) Our Base: 4.5kg (▲10% lighter) Our Advanced: 4kg (▲▲20% lighter) | Base: Easier handling; Advanced: Ultra-compact for tight spaces ▲▲ | Advanced may sacrifice some durability ▲▲ |

⭐⭐⭐⭐⭐ James Wilkins - Senior Maintenance Technician, PrintPro Solutions

"We replaced our aging plastic actuators with the Technotrans SSC61 Base Model across three offset printing lines. After 5 months of continuous operation, zero failures. The stainless steel build is a game-changer—no more warping near heated rollers. The manual knob allows quick field adjustments during press changeovers, and the CE certification gave our safety team peace of mind."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Automation Engineer, FlexiPrint Industries

"We integrated the Technotrans SSB61 Pro Model into our high-speed printing line with IoT-enabled monitoring. The IP67 rating has held up perfectly in our humid press room, and the 30% higher torque handles thicker ink viscosity without lag. Real-time diagnostics via the smart control system have cut unplanned downtime by 40%. Worth every penny for large-scale operations."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Chen - Owner, MetroPrint Workshop

"Bought the Advanced Model for our mid-sized offset machine. Installation was smooth thanks to the universal flange and clear wiring guide. The 20% faster response time is noticeable—less stutter during startup. Only reason I’m not giving 5 stars is that the semi-automatic interface took some training for our older staff. But once set up, performance has been rock solid."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Anita Patel - Field Service Engineer, PrintTech Services

"I’ve retrofitted over 20 legacy Heidelberg systems, and the Technotrans SSC61/SSB61 is the most compatible electrical actuator I’ve used. The three-wire connection standardizes well with older control panels, and the compact design fits where others don’t. We’ve had zero compatibility issues. Their engineering team even helped us customize flange sizes for a 1990s Komori press—outstanding support."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Reed - Operations Manager, National Print Hub

"After switching to the Pro Model across our facility, we’ve seen a measurable improvement in print consistency. The ±0.1mm precision control minimizes ink misalignment, especially at 12,000 impressions per hour. With predictive maintenance alerts from the IoT module, we’re staying ahead of wear issues. Two years into a tight production schedule and not a single actuator failure."Purchase Date: April 2024 | Usage Period: 11 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Lin - Industrial Automation Consultant

"In high-cycle printing environments, reliability and precision are non-negotiable. The Technotrans SSC61/SSB61 series stands out with its stainless steel durability, dual-control flexibility, and IP67-rated Pro variant. For any facility upgrading from pneumatic or plastic actuators, this is the gold standard for modern offset printing systems."

Tomás Alvarez - Lead Integration Engineer, PrintSys Global

"I’ve evaluated dozens of actuators for printing machinery integration. The Technotrans models offer the best balance of standardization and customization. Their CE + RoHS + UL compliance makes them viable for global deployments, and the ability to tailor control interfaces ensures seamless fit into mixed-vintage production floors."

Posted: 2 days ago

"The Advanced Model’s faster response time reduced ink waste by 15% in our test run. Durable, quiet, and easy to integrate. Tech support responded within 2 hours to a wiring query—impressive service."

Posted: 1 week ago

"We needed a robust actuator for a cramped retrofit. The compact flange design saved us from reconfiguring the entire manifold. Stainless steel body looks pristine after 6 months of daily washdowns."

Posted: 3 weeks ago

"The smart control on the Pro Model is powerful but requires proper setup. Once calibrated, it’s been flawless. Would love a quick-start video guide for new users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.