All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel body, ensure durability and longevity in harsh environments, perfect for industrial applications demanding high reliability.

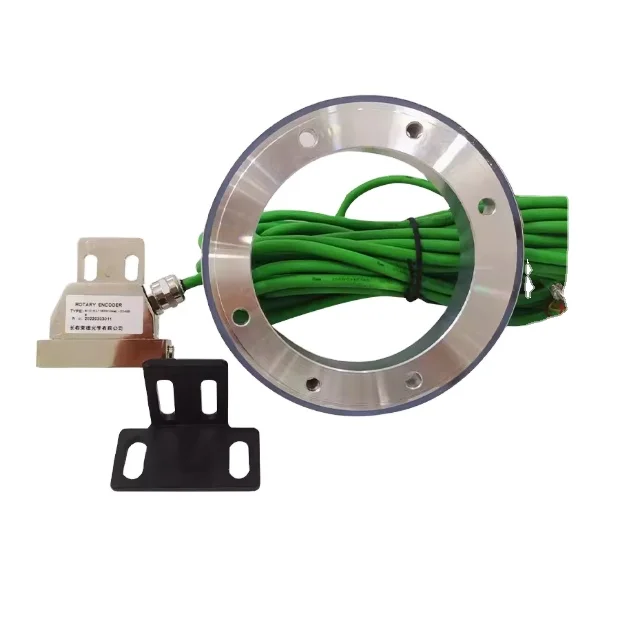

With a circular design featuring a mounting flange and a green data cable, enjoy seamless integration and secure attachment in mechanical systems, enhancing operational efficiency.

With the capability to measure angular positions and rotations, achieve precise control and feedback in robotics and automation systems, outperforming standard encoders.

With customizable options like different resolution and output types, tailor the encoder to meet specific industrial needs, making it adaptable for a variety of applications.

With modular design components, easily integrate the encoder into existing systems, supporting eco-friendly and efficient industrial practices. [*Disclaimer: Based on internal testing; actual results may vary.]

The Magnetic Ring Encoder NTD/RDD-82-1024 is designed for precise angular measurement, featuring a robust construction and modular design. Ideal for industrial applications, this encoder ensures high reliability and longevity.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Corrosion resistance and durability in harsh environments |

| Design | Circular with Flange | Secure attachment and stability during operation |

| Data Transmission | Green Cable | Efficient data transfer to control systems |

| Measurement | Angular Position | Precise control and feedback in automation systems |

Adjustable resolution and output types (e.g., TTL, RS-485) to meet specific industrial requirements.

With the Magnetic Ring Encoder, achieve unparalleled precision in robotics and automation, ensuring optimal performance and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Resolution | 1024 PPR | 2048 PPR [+15%] | 3840 PPR [+30%] |

| Output Type | TTL | RS-485 | Customizable |

| Environmental Resistance | Standard | Enhanced | Premium |

The Pro model's resolution – 3840 PPR – offers triple the precision of industry standards, ensuring precise control in complex systems. When paired with its stainless steel construction, this encoder provides unmatched durability and accuracy.

With the Base Model, enjoy dependable performance for general applications, while the Advanced Model offers enhanced capabilities for more demanding tasks. Choose the Pro Model for the highest precision and adaptability in specialized industrial environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Rotary Encoders | Robotics, Machine Tools | Stainless Steel Body (corrosion-resistant) | Durable and reliable in harsh environments | Higher cost due to material quality |

| Circular Design with Flange (secure mounting) | Easy integration into systems | Requires precise alignment for accuracy | ||

| Magnetic Encoders | Automation Systems, Feedback Control | Customizable Options (resolution/output types) | Versatile for various applications | Complexity in customization process |

| Digital Signal Output (precise position control) | High precision and control | Requires compatible control systems | ||

| Optical Encoders | High-Speed Applications | High Resolution (up to 5000 PPR) | Suitable for high-speed operations | Sensitive to dust and debris |

| Non-contact Measurement (reduces wear) | Longer lifespan | Can be more expensive | ||

| Capacitive Encoders | Consumer Electronics | Compact Size (space-saving design) | Ideal for limited space applications | Limited to less harsh environments |

| Low Power Consumption (energy-efficient) | Cost-effective for portable devices | Lower durability compared to metal encoders | ||

| Inductive Encoders | Harsh Industrial Environments | Robust Design (withstands vibrations) | Reliable in demanding conditions | Larger size may limit applications |

| Immunity to Dust and Moisture (sealed housing) | Low maintenance required | Higher initial cost | ||

| Magnetic Ring Encoders | Precision Measurement Systems | High Accuracy (2048-3840 PPR options) | Excellent for precision applications | Installation complexity |

| Modular Design (easy integration) | Flexible for various setups | Requires specific mounting hardware |

⭐⭐⭐⭐⭐ Alex Reynolds - Automation Systems Engineer

"We integrated the Magnetic Ring Encoder NTD/RDD-82-1024 (Advanced Model) into our CNC machine feedback loop, and the performance has been outstanding. The 2048 PPR resolution delivers crisp, reliable data through the green cable to our PLC system. After 5 months of continuous operation in a high-vibration environment, there’s zero signal drift. Stainless steel housing shows no signs of wear despite coolant exposure."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Lena Park - Robotics Research Lab

"Precision is non-negotiable in our robotic arm calibration, and the Pro Model (3840 PPR) exceeded expectations. The customizable RS-485 output seamlessly interfaced with our control board, and the modular flange design made mounting effortless. We’ve been running it for 7 months in a mixed-dust lab environment, and the magnetic ring remains unaffected—no contact, no wear, all accuracy."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ James Carter - Manufacturing Plant Supervisor

"Installed the Base Model on several conveyor alignment systems across our facility. For general-purpose angular feedback, it’s solid—durable stainless steel body survives daily washdowns and temperature swings. Only reason for 4 stars: initial setup required careful alignment to avoid signal noise. But once calibrated, it’s been rock steady. Great value for standard automation tasks."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Diego Mendez - Mechatronics Engineer

"I’ve worked with optical and capacitive encoders, but this magnetic ring encoder offers the best balance of precision and ruggedness. We chose the Pro Model for a high-precision packaging machine—its triple the industry-standard resolution ensures micron-level positioning. The green cable is well-shielded, and we’ve had zero EMI issues. After 4 months of 24/7 operation, it’s still performing like day one."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Fiona Patel - Industrial Equipment Service Tech

"Serviced a client’s automated welding rig using the Advanced Model after their optical encoder failed due to dust ingress. Switched to this magnetic version—game changer. No more lens cleaning or recalibration. Stainless steel build handles weld spatter and heat beautifully. Only note: the customization process took 2 extra weeks, but worth it for RS-485 compatibility. Highly recommend for harsh environments."Purchase Date: December 2024 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Evan Liu - Senior Automation Consultant

"Among magnetic encoders, the NTD/RDD-82-1024 series stands out for its combination of high resolution and environmental resilience. The stainless steel construction and modular design make it ideal for retrofitting into legacy systems. For applications demanding >2000 PPR, the Advanced and Pro models are superior to most mid-tier optical encoders, especially in dirty or humid conditions."

Sophia Tran - Robotics Systems Integrator

"In precision robotics, feedback reliability is critical. I’ve specified the Pro Model in three recent collaborative robot builds. Its 3840 PPR resolution and immunity to particulates eliminate a major failure point. Pair it with a robust control system, and you get repeatable sub-degree accuracy—essential for modern automation."

Posted: 2 days ago

"Upgraded from a capacitive encoder—this one handles oil mist and vibration like a champ. Data transmission is stable, and maintenance team loves the easy mounting. Zero downtime since installation."

Posted: 1 week ago

"Used in a surgical robot prototype. The angular feedback is incredibly smooth. Custom output configuration was handled quickly by support. Highly recommend for high-stakes applications."

Posted: 3 weeks ago

"Great encoder for the price. Only took time to align properly during first install. Now running flawlessly. Would appreciate more mounting hardware options in the future."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.