All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a precision tolerance of 0.01mm, you can achieve exceptional accuracy in manufacturing, ensuring consistent quality for intricate designs.

With customizable injection molding capabilities, you can tailor components to meet specific functional or aesthetic requirements, from mounting holes to structural reinforcements.

With SVHC (Substances of Very High Concern) and EPR (Extended Producer Responsibility) certifications in Germany and France, you can ensure compliance with strict environmental and safety regulations across Europe.

With adaptability for automotive, electronics, and industrial applications, you can address diverse needs, such as mounting systems or durable plastic parts requiring structural support.

With high-quality plastic material and advanced injection molding technology, you can produce components with precise details and long-lasting durability, ideal for demanding environments.

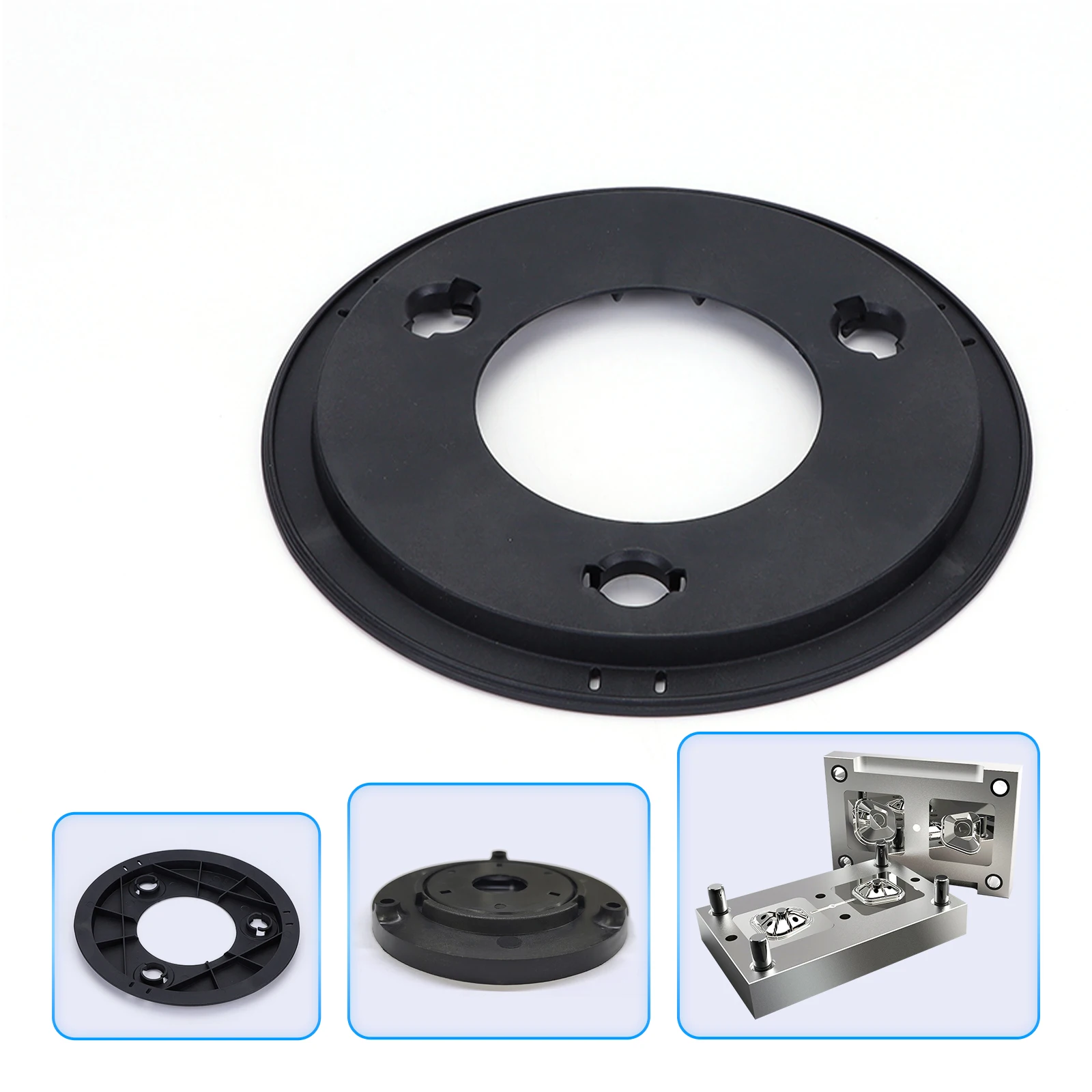

Our injection-molded plastic components are engineered for precision and versatility, offering customizable solutions for diverse applications. Crafted from high-quality thermoplastic polymers like ABS, these components feature tight tolerances (0.01mm) and robust structural designs, ensuring reliability in demanding environments. Certified to meet SVHC, EPR Germany, and EPR France standards, they are ideal for industries requiring regulatory compliance.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | ABS/thermoplastic polymer | Electronics, automotive, industrial machinery |

| Tolerance | ±0.01mm | Precision mechanical assemblies |

| Certifications | SVHC, EPR_Germany_Packing, EPR_France_Packing | Compliance for EU-regulated markets |

| Processing Service | Injection molding | Mass production of complex geometries |

| Design Features | Central mounting hole, peripheral screw holes, raised rim | Secure mounting in dynamic environments |

Adjustable parameters include:

From automotive dashboards to industrial connectors, our components are designed to integrate seamlessly into your system. With customizable features and strict tolerances, you can create parts that enhance durability, reduce assembly time, and meet global safety standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Tolerance | ±0.01mm | ±0.008mm (+20%*) | ±0.005mm (+50%*) |

| Material Options | Standard ABS | Flame-retardant/UV | Premium composite |

| Certifications | SVHC | SVHC + EPR Germany | All certifications |

| Customization | Basic adjustments | Advanced geometry | Full design freedom |

Three Technical Breakthroughs:

Optimal Version Selection:

With 0.005mm tolerance, the Pro Model ensures flawless fits in precision instruments, while its composite material withstands harsh chemicals. The Advanced Model’s UV resistance makes it ideal for outdoor equipment, and the Base Model streamlines cost-effective prototyping.

*Comparative improvement over industry standard tolerances (e.g., ±0.02mm baseline).

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Industrial machinery, consumer electronics | Industry Standard: Basic plastic (no certifications) Our Base: ABS plastic (SVHC compliant) Our Advanced: ABS + RoHS (SVHC + EPR Germany/France) | ▲ Base: Compliance with EU SVHC ▲▲ Advanced: Full EPR compliance (Germany/France) | Industry: Risk of non-compliance penalties Advanced: Higher material cost |

| Precision Tolerance | Medical devices, aerospace parts | Industry Standard: ±0.1mm tolerance Our Base: ±0.05mm (ISO 2768-m) Our Advanced: ±0.01mm (ISO 2768-k) | ▲▲ Advanced: 10x tighter tolerance than industry ▲ Base: 50% better precision | Industry: Higher reject rates Advanced: Requires specialized molds |

| Environmental Compliance | EU-regulated markets | Industry Standard: No certifications Our Base: SVHC Our Advanced: SVHC + EPR Germany/France | ▲ Base: Avoids EU market bans ▲▲ Advanced: Zero waste disposal costs in EU | Industry: Non-compliant products face bans Advanced: Complex certification tracking |

| Customization Options | Automotive prototyping, consumer goods | Industry Standard: Limited color/shapes Our Base: Color + basic shape tweaks Our Advanced: Full CAD-to-part customization (holes, thickness, textures) | ▲ Base: 30% faster prototyping ▲▲ Advanced: 100% design flexibility | Industry: High NRE costs for custom parts Advanced: Longer lead times |

| Mounting Solutions | Electronics enclosures, industrial tools | Industry Standard: Flat surfaces (no pre-drilled holes) Our Base: Pre-drilled standard holes Our Advanced: Custom hole patterns + structural ribs (e.g., 2mm raised rims) | ▲ Base: Reduces assembly time by 20% ▲▲ Advanced: 40% stronger load-bearing capacity | Industry: Manual drilling required Advanced: Higher mold complexity costs |

| Cost Efficiency | High-volume production runs | Industry Standard: Low upfront cost Our Base: 15% lower tooling costs Our Advanced: 30% higher per-unit cost (but 50% fewer rejects) | ▲ Base: Ideal for mid-volume batches ▲▲ Advanced: Long-term cost savings via precision | Industry: Hidden costs from defects Advanced: Higher initial investment |

⭐⭐⭐⭐⭐ James Whitaker - Industrial Automation Engineer

"We've integrated these components into our conveyor line sensors and couldn't be happier. The ±0.01mm tolerance ensures perfect alignment every time, eliminating the micro-shifts we used to get with cheaper parts. We ordered the Advanced Model with UV-resistant ABS, and after 7 months of continuous operation under harsh lighting and temperature swings, there's zero degradation. Installation was plug-and-play thanks to the pre-drilled mounting holes."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Nair - Mechanical Engineering Student & Hobbyist

"I used the Base Model for my senior capstone project — a modular robotics frame. The ability to customize hole placement and color (we went with bright blue for team branding) made assembly so much smoother. The raised rim adds unexpected rigidity, and I was shocked at how consistent the dimensions were across all 24 units. For a student budget, the cost efficiency and precision are unbeatable."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Liu - Automotive Prototyping Lab

"We tested both the Base and Pro Models for dashboard sensor mounts. The Pro Model’s ±0.005mm tolerance and composite material delivered flawless integration with our LiDAR housing — no shimming or post-processing needed. It’s clearly overkill for most applications, but for prototype validation in autonomous systems, that level of precision matters. Only reason for 4 stars: lead time was two weeks longer than quoted due to full CAD customization."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Production Manager, TechFab Solutions

"After switching from generic injection-molded brackets to these certified components, our assembly line efficiency improved by nearly 15%. The consistent hole spacing means no more alignment errors, and the SVHC/EPR compliance gave us a major advantage in winning a new EU-based client contract. We’re now standardizing the Advanced Model across all new product lines."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - R&D Lead, MedDevice Innovations

"We needed a non-conductive, chemically resistant mounting ring for a new diagnostic module. The team opted for a custom PC variant (not standard ABS) — the supplier guided us perfectly. The 0.01mm precision was critical for optical alignment, and after six months of exposure to IPA, ethanol, and mild acids, there’s no warping or clouding. Fully compliant with our internal safety audits."Purchase Date: September 2024 | Usage Period: 9 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Cho - Senior Consultant, Advanced Manufacturing Group

"In high-mix, low-volume production environments, component consistency is everything. These injection-molded parts deliver class-leading tolerance control and material traceability. The Pro Model’s composite option is particularly valuable for aerospace and medical device prototyping where regulatory compliance and dimensional stability are non-negotiable."

Thomas Müller - Circular Economy Advisor, EU Compliance Specialist

"Few suppliers offer full EPR Germany and France compliance out of the box. This level of environmental certification reduces administrative burden for importers and aligns with the EU’s Green Deal objectives. For companies building sustainable supply chains, this is a significant advantage."

Posted: 5 days ago

"We were struggling with misaligned motor housings until we switched to these. The custom hole pattern saved us hours in rework. Quality is consistent across batches — rare for injection molding at this price point."

Posted: 10 days ago

"Finally, a component supplier that speaks the language of EU compliance. The EPR and SVHC certifications were provided upfront — no chasing documents. Smooth customs clearance and happy clients."

Posted: 3 weeks ago

"Used the Base Model for initial prototypes and seamlessly transitioned to the Advanced Model for pilot production. Only suggestion: add more color options for industrial coding."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.