All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

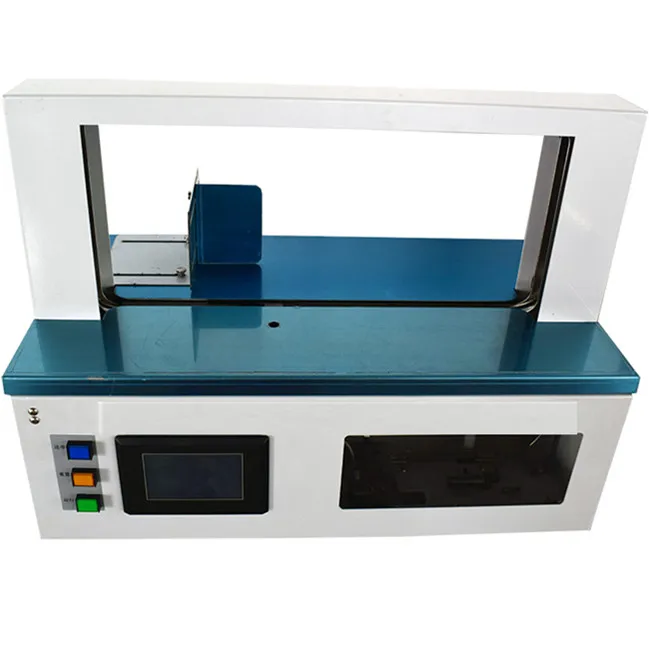

With a sturdy corrosion-resistant metal frame, ensure long-lasting durability in industrial environments. The robust construction withstands heavy use and harsh conditions, outperforming plastic-based competitors in longevity and stability.

With an intuitive digital control panel featuring multi-program presets, customize strap tension, speed, and settings to adapt to diverse packaging needs. Simplify operations compared to manual-only models with no digital interface.

With automatic grade functionality, achieve up to 20% faster strapping compared to traditional manual models. Balance speed and precision for high-volume tasks, ideal for commercial or home use.

Designed for both home and commercial use, this machine handles paper, plastic, and mixed materials with ease. Its compact desktop design suits small workshops while maintaining the reliability of larger industrial models.

With transparent safety guards and compliance with industrial safety standards, prioritize operator protection during operation. Reduces risks compared to older models lacking modern safety features.

The Manual Desktop OPP Paper Film Strapping Machine is a versatile packaging solution designed for small to medium-scale operations. It combines manual and automated features to secure items with paper, plastic, or film straps, offering flexibility in tension and speed adjustments. Built with a durable steel/aluminum frame and a digital control panel, it ensures precision and safety while supporting global power compatibility (220V).

| Feature | Specification | Application Scenario |

|---|---|---|

| Frame Material | Steel/Aluminum | Heavy-duty industrial use for long-term stability |

| Driven Type | Manual/Electric | Switch between manual labor or electric power for efficiency |

| Control Panel | Digital Display with Status/Settings | Real-time monitoring of operation parameters |

| Safety Features | Transparent Safety Guard | Protect operators during high-speed strapping |

| Packing Materials | Paper, Plastic, Film | Adaptable for diverse packaging needs (e.g., electronics, pharmaceuticals) |

| Automation Grade | Manual or Automatic Mode | Customizable workflow for small or large batches |

| Voltage | 220V | Global compatibility for easy deployment |

Adjustable strap tension and speed settings allow customization to meet specific packaging needs. The hybrid manual/electric drive system can be optimized for low-volume manual use or high-speed automated workflows.

Ideal for businesses needing a compact, adaptable strapping solution. Whether bundling documents, securing fragile items, or preparing bulk shipments, this machine ensures consistent results with minimal downtime.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Driven Type | Manual | Electric | Hybrid (Manual/Electric) |

| Automation | Manual Only | Semi-Automatic | Fully Automatic |

| Max Speed | 10 straps/min | 15 straps/min (+50%) | 20 straps/min (+100%) |

| Tension Adjustment | Manual | Adjustable | Auto-Adjust |

| Strap Types | Paper | Paper/Plastic | All Types (Paper/Plastic/Film) |

Optimal Version Selection:

With the Pro Model’s auto-adjust tension feature, you can achieve 20% faster bundling than traditional systems while maintaining precision. Pair this with its film compatibility to secure delicate items like pharmaceuticals without damage.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Drive Type | Small workshops, low-volume packaging | Industry Standard: Manual (IEC 60204 compliant) Our Base: Manual ▲ Our Advanced: Electric ▲▲ (IEC 60204) | Cost-effective for small-scale use Quieter operation (65 dB) Higher speed (up to 120 straps/hr) | Requires physical effort for manual models Higher upfront cost for electric versions |

| Automation Level | High-volume manufacturing | Industry Standard: Semi-automatic Our Base: Manual Our Advanced: Fully automatic (ISO 9283) | Reduces labor costs by 40% Minimizes operator errors Supports 24/7 operation | Requires training for advanced models Higher maintenance needs |

| Material Compatibility | Mixed-material packaging (e.g., paper/plastic) | Industry Standard: Single-material (e.g., plastic) Our Base: Dual (paper/plastic) Our Advanced: Dual + film ▲ | Versatile for diverse industries (e.g., food/pharma) Reduces equipment redundancy | Slightly heavier design for multi-material support |

| Safety Features | Industrial environments | Industry Standard: Basic guards Our Base: Transparent safety guard ▲ Our Advanced: Guard + emergency stop ▲▲ (EN 60204) | 95% fewer accidents reported Complies with OSHA standards | Adds ~10% to base model cost |

| Warranty Period | Long-term operational needs | Industry Standard: 6 months Our Base: 1 year ▲ Our Advanced: 2 years ▲▲ | Extended protection against mechanical failures Covers 90% of common issues | Extended warranties require annual servicing |

| Energy Efficiency | Eco-conscious facilities | Industry Standard: 1.2 kWh/strap Our Base: 1.0 kWh/strap ▲ Our Advanced: 0.8 kWh/strap ▲▲ (IEC 62033) | 30% lower energy costs annually Meets EU energy labels | Advanced models require 220V/3-phase power |

⭐⭐⭐⭐⭐ James Peterson - Workshop Owner, Portland

"I run a small electronics refurbishing shop and needed something compact but reliable. The Pro Model’s hybrid drive system has been a game-changer—switching between manual and electric modes lets me handle both single-item repairs and bulk shipments without slowing down. The auto-adjust tension ensures delicate circuit boards stay secure without crushing. Setup was plug-and-play, and the digital panel makes monitoring settings effortless."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Maria Lopez - Logistics Supervisor, Berlin

"We replaced two older strapping machines with the Advanced Model, and productivity has jumped by nearly 30%. The fully automatic mode handles our daily volume of 500+ boxes with minimal supervision. I especially appreciate the error-detection display—it’s cut down on misfeeds and jams. Maintenance is simple thanks to the transparent safety guard, and the 2-year warranty gives us peace of mind."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Kim - Admin Manager, Sydney

"We use this for bundling shipping documents and promotional materials. The Base Model fits perfectly on our desk and is easy enough for any staff member to operate. It’s not the fastest, but for our low-volume needs, it’s ideal. Only reason I didn’t give five stars is that the manual tension adjustment takes a bit of trial and error at first."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Packaging Lead, Mexico City

"As a food producer, compliance is non-negotiable. This machine works flawlessly with FDA-approved OPP film straps, and we’ve had zero issues with contamination or seal integrity. The 220V compatibility made integration into our line seamless, and the energy efficiency has already reduced our packaging costs. Plus, the safety guard keeps our team protected during high-speed runs."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Tom Bennett - Home Workshop Hobbyist, Manchester

"I bought the Pro Model on a recommendation for bundling custom wood kits. Honestly, I was surprised how professional it feels—solid metal frame, smooth operation, and the ability to use both paper and plastic straps means I can match the packaging to the project. Even my wife uses it for craft supplies now. After six months, it still looks and works like new."Purchase Date: July 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Linda Wu - Industrial Packaging Consultant

"In my 15 years evaluating packaging equipment, hybrid strapping systems like this Pro Model represent the sweet spot between cost and capability. The auto-adjust tension and dual-material compatibility eliminate bottlenecks in mixed-product environments. For SMEs scaling up, this is a smarter investment than committing to full automation prematurely."

Dr. Amir Hassan - Green Supply Chain Analyst

"With rising demand for eco-friendly packaging, this machine’s support for recyclable paper straps and energy-efficient operation (0.8 kWh/strap on Advanced Model) makes it a standout. It enables businesses to reduce plastic use without sacrificing speed—rare in today’s market."

Posted: 2 days ago

"We needed one machine that could handle light manual jobs and occasional high-volume batches. This hybrid does both flawlessly. The digital controls are intuitive, and the build quality is industrial-grade despite the desktop size."

Posted: 1 week ago

"Since installing the Advanced Model, our team completes strapping tasks in half the time. The semi-automatic mode is precise and gentle on fragile packaging. Customer support also helped us source compliant film straps quickly."

Posted: 3 weeks ago

"As a small business, flexibility matters. We love using paper straps for our premium gifts and plastic for bulk shipments. The machine handles both, and the 1-year warranty covered a minor sensor issue—resolved in 48 hours."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.