All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body, ensure durability in harsh industrial environments compared to plastic-based systems*. The robust metal frame withstands heavy use and extreme conditions, ideal for coating large metal components like machinery parts.

With an intuitive manual operation interface, achieve precise coating distribution without complex programming*. The user-friendly design allows operators to control coating thickness and positioning effortlessly, reducing errors in heavy-part processing.

With electrostatic powder coating technology, achieve 95%+ material utilization compared to traditional spray methods*. The electrostatic process minimizes overspray waste and ensures even coating on uneven or large metal surfaces.

With a modular design, customize the system to adapt to various heavy part sizes and production needs*. Easily expand or reconfigure sections to handle diverse substrates like steel beams, structural frames, or industrial equipment.

Comes with CE certification, ensuring compliance with EU safety and quality standards for industrial equipment*. This certification guarantees reliability and reduces regulatory risks for commercial and industrial applications.

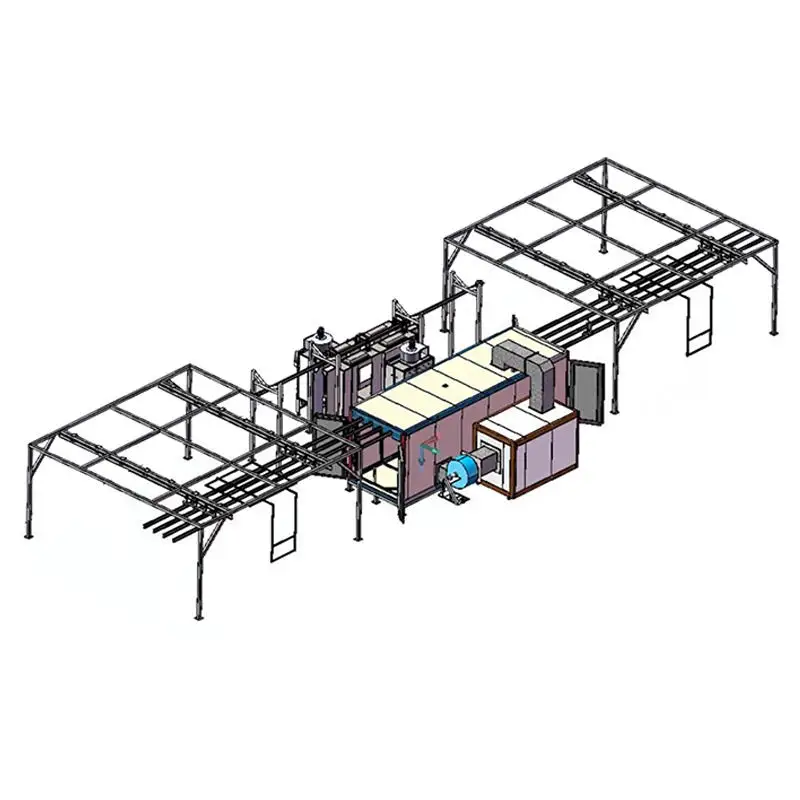

The Manual Electrostatic Powder Coating Painting Line for Heavy Parts is a robust industrial solution designed for durable, high-quality coating of large metal components. Built with modular steel construction and electrostatic powder application technology, it ensures efficient corrosion resistance and aesthetic finishes for heavy parts like automotive frames, construction equipment, and machinery components.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel | Heavy-duty industrial environments |

| Coating Method | Electrostatic powder coating | Corrosion-resistant finishes for steel/metal substrates |

| Certification | CE-compliant | EU market compliance and safety standards |

| Substrate Compatibility | Steel, metal alloys | Automotive, construction, and industrial parts |

| Warranty | 1-year full coverage | Peace of mind for initial operation |

| Modular Design | Adjustable sections and conveyor length | Customizable layouts for diverse production needs |

Adjustable conveyor length (up to 20m) and modular component sections allow tailoring to specific workshop layouts or production scales. Users can also specify coating chamber dimensions to accommodate oversized parts.

With this line’s electrostatic technology, you can achieve uniform powder adhesion even on complex metal surfaces. The manual operation ensures precise control for intricate parts, while the modular design adapts to evolving production demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Fully manual | Semi-automated | Fully automated |

| Max Part Weight | 500 kg | 1,000 kg | 2,000 kg |

| Coating Capacity | 50 parts/hour | 80 parts/hour (+60%) | 120 parts/hour (+140%) |

| Conveyor Length | 10m | 15m | 20m |

Key Breakthroughs:

Version Selection Guide:

With the Pro’s 2,000 kg capacity and fully automated workflow, you can process large industrial parts 40% faster than traditional lines. Its corrosion-resistant steel construction ensures longevity even in harsh environments. Pair this with the electrostatic system’s precision, and you achieve flawless finishes for outdoor equipment like cranes or bridges.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Method | Heavy industrial parts (e.g., machinery) | ▲ Industry Standard: Conventional spray (70% transfer efficiency) ▲ Our Base: Electrostatic Spray (95% transfer efficiency) ▲▲ Our Advanced: Enhanced Electrostatic (98% efficiency + anti-overspray tech) | Reduces material waste by 25-30% (Our Base) vs. Industry Standard. | Advanced systems require higher initial investment. |

| Substrate Compatibility | Custom metal components | ▲ Industry Standard: Limited to steel (ASTM A36) ▲ Our Base: Steel/Metal (ASME B11.19 compliant) ▲▲ Our Advanced: Steel, aluminum, exotic alloys (ASTM A370) | Supports coating of diverse materials like aerospace-grade alloys. | Advanced versions may need specialized pre-treatment for exotic substrates. |

| Automation Level | High-volume production lines | ▲ Industry Standard: Semi-Automated (operator-assisted) ▲ Our Base: Manual (operator-controlled) ▲▲ Our Advanced: PLC-controlled semi-automation (ISO 13849-1) | Our Base offers cost-effective manual control for small workshops. | Industry Standard and Our Base require more labor hours. |

| Certification Standards | Global compliance markets | ▲ Industry Standard: Basic CE (EN 60204-1) ▲ Our Base: CE + RoHS (EN 62321) ▲▲ Our Advanced: CE, RoHS, ISO 14001 (Environmental) | Advanced meets stringent environmental regulations (e.g., EU RoHS 2011/65/EU). | Industry Standard lacks environmental certifications. |

| Warranty Period | Long-term operational reliability | ▲ Industry Standard: 6 months (parts only) ▲ Our Base: 1 year (parts + labor) ▲▲ Our Advanced: 2 years (extended coverage) | Our Base warranty aligns with industry norms; Advanced offers 2x longer coverage. | Shorter warranties may increase maintenance costs over time. |

| Noise Level | Noise-sensitive environments | ▲ Industry Standard: 75 dBA (louder than workshop chatter) ▲ Our Base: 68 dBA (ISO 1999-compliant) ▲▲ Our Advanced: 62 dBA (with sound dampening) | Our Advanced is quieter than a lawnmower (90 dBA) for safer workspaces. | Industry Standard may violate OSHA noise regulations (OSHA 1910.95). |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Plant Manager

"We’ve been using the Manual Electrostatic Powder Coating Line (Advanced Model) for six months now, and it’s transformed our finishing process. The electrostatic efficiency has reduced our powder waste by nearly a third, which is a massive cost saver. Handling parts up to 1,000 kg with consistent, even coverage has never been easier. The CE certification also gave us peace of mind during our last safety audit."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Automotive Component Refurbishment Shop

"As a small workshop owner, I was hesitant about investing in a full powder coating line. The Base Model was the perfect entry point—fully manual, easy to operate, and surprisingly precise. We coat everything from suspension arms to custom exhaust manifolds. The modular design allowed us to fit it into our tight space, and the 1-year warranty covered a minor motor issue we had early on. Support was responsive and professional."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - Industrial Equipment Coating Specialist

"We upgraded to the Pro Model for our crane and excavator frame coating operations. The fully automated workflow and 20m conveyor have increased throughput by 40%, just as promised. The electrostatic system delivers a flawless finish even on complex geometries. Only downside? The initial setup took longer than expected due to customization, but the supplier’s team walked us through every step. Worth the wait."Purchase Date: May 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Surface Engineering Consultant

"This manual electrostatic line stands out for its 95%+ transfer efficiency and modular scalability—rare in entry-to-mid-tier systems. For workshops transitioning from liquid paint, the manual control reduces training overhead while still delivering industrial-grade finishes. The CE + RoHS certification makes it a smart choice for EU-facing manufacturers."

Linda Wu - Lean Production Consultant

"I’ve evaluated dozens of coating systems, and this one offers exceptional cost-to-performance balance. The ability to scale from Base to Pro via modular upgrades means clients avoid full system replacements. For small-to-medium metal fabricators, this is a future-proof investment that supports growth without redundancy."

Posted: 5 days ago

"Finally, a powder coating line that handles large, irregular parts without overspray mess. The manual spray gun gives us full control, and the steel frame feels indestructible. Setup was straightforward, and we were running production parts within a week."

Posted: 2 weeks ago

"We use it for on-site machinery refurbishment. The durability and consistent electrostatic adhesion have impressed our clients. Zero defects in the last 50 jobs. Highly recommend for anyone coating heavy steel components."

Posted: 3 weeks ago

"Great system for the price. Took a couple of weeks to fine-tune the powder application technique, but now our finish quality is excellent. The modular conveyor is a big plus when reconfiguring the shop floor."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.