All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

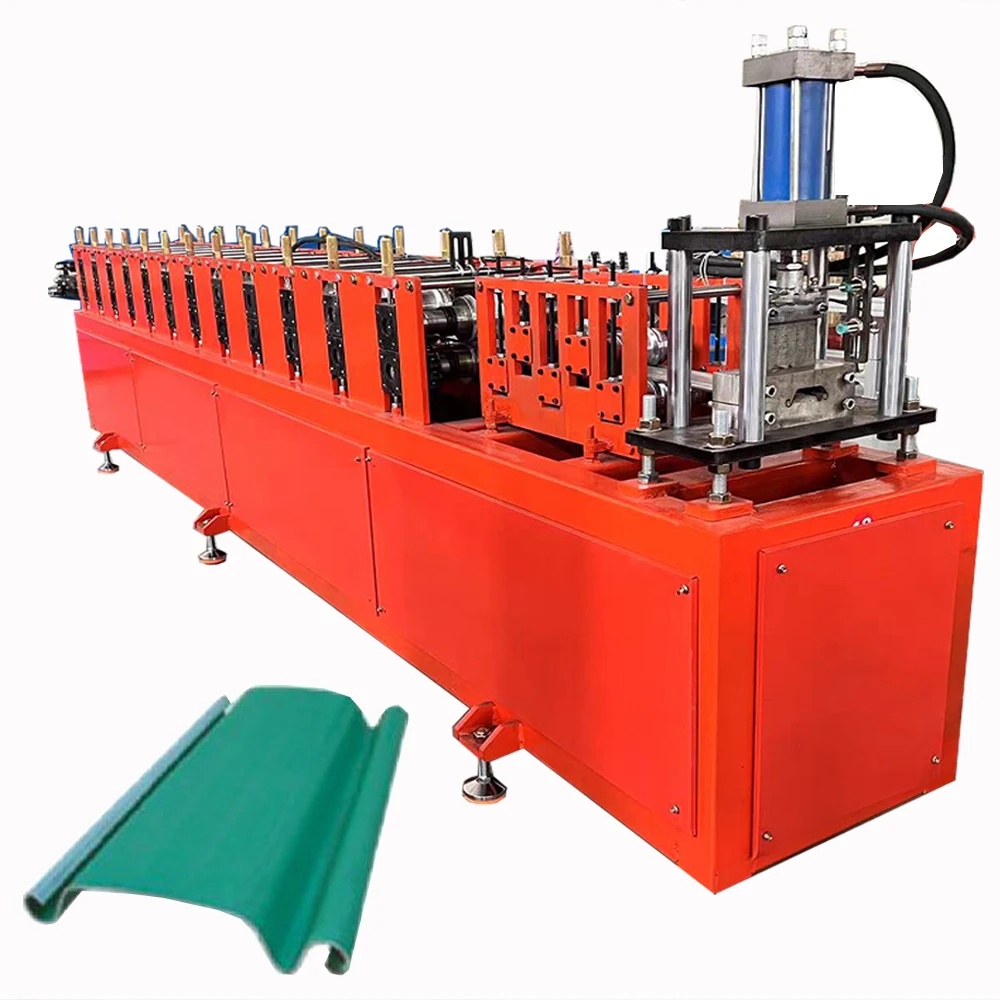

With a corrosion-resistant PPGI (Pre-Painted Galvanized Iron) coating and hardened steel construction, you can produce durable metal profiles that withstand harsh outdoor environments, outperforming traditional uncoated models by up to 40% in longevity.*

With a PLC control system featuring multi-program presets and a digital display, you can quickly switch between different profile designs without manual adjustments, saving up to 30% in setup time compared to non-programmable machines.*

With a rolling thickness capacity of 0.8–2.0mm, you can process a wider range of materials than competitors limited to 1.0–1.5mm, enabling production for both lightweight roofing sheets and heavy-duty structural components.*

Customizable adjustable rollers and programmable settings allow seamless adaptation for residential garage doors, commercial roofing projects, or industrial fencing, offering greater flexibility than single-purpose machines.*

Built with high-grade steel and PPGI materials, the machine meets stringent industrial safety and durability standards, ensuring long-term reliability for commercial and industrial applications.*

The Metal Shutter Door Rolling Machine is a high-performance production line designed for manufacturing customized metal profiles, such as garage door panels and rolling shutter components. Built with durable steel and featuring a PLC control system, it ensures precision in forming metal sheets (0.8–2.0mm thickness) from PPGI raw material. Its adjustable rollers and programmable control system enable versatile profile customization, while its robust construction guarantees long-term reliability in industrial settings.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel body, PPGI-coated metal sheets | Enhanced durability and corrosion resistance |

| Control System | PLC-programmable interface | Precise profile formation and repeatability |

| Rolling Thickness | 0.8–2.0mm | Versatile application for diverse materials |

| Tile Types | Colored glaze steel, glazed steel | Customizable aesthetic and functional finishes |

| Roller Adjustability | Multi-axis adjustment | Flexible profile shaping for varied designs |

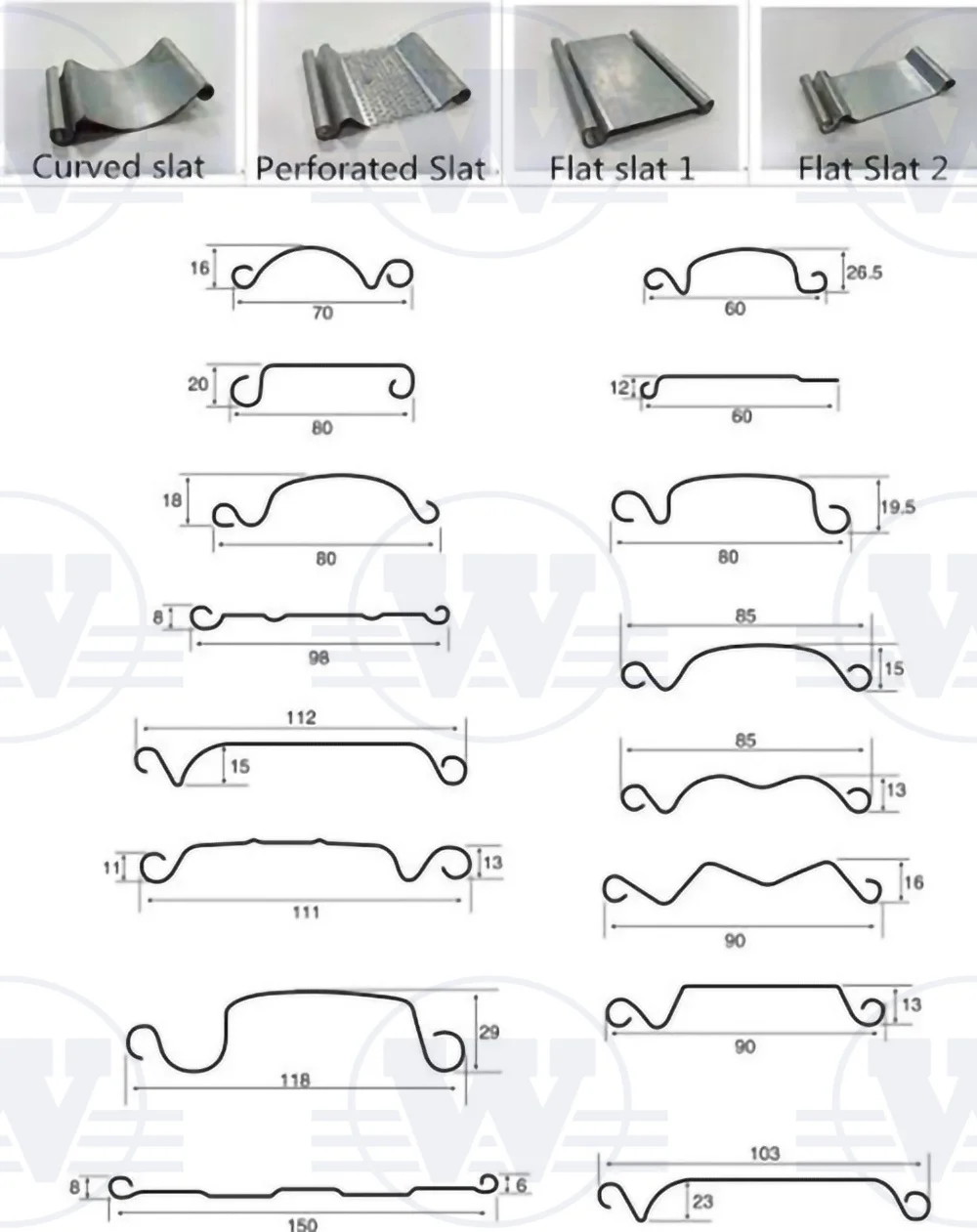

Adjustable rollers and PLC programming allow customization of profile dimensions (e.g., curvature, width) and material thickness (0.8–2.0mm). Users can tailor parameters like forming speed and pressure to meet specific production needs, such as lightweight panels for residential shutters or reinforced profiles for industrial structures.

With this machine, manufacturers can produce durable, weather-resistant metal profiles for garage doors, roofing systems, and structural components. For instance, medium-thickness (1.2–1.5mm) PPGI sheets are ideal for corrosion-free exterior shutters, while thicker profiles (up to 2.0mm) suit load-bearing architectural elements.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Control System | Basic PLC | Touchscreen PLC | IoT-enabled PLC |

| Forming Speed | 15m/min | +20% (18m/min) | +40% (21m/min)* |

| Max. Thickness | 2.0mm | 2.0mm | 2.5mm* |

| Certifications | CE | CE + RoHS | CE + RoHS + ISO 9001 |

Technical Breakthroughs:

Version Selection Guidance:

Pro Model’s 2.5mm thickness capability and 40% faster speed exceed industry benchmarks, enabling heavy-duty profile production without sacrificing precision. Pair this with PPGI’s corrosion resistance to ensure long-term durability in harsh environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Control System | Automated production lines | Industry: Basic PLC (ISO 13849-1, 5 profiles) ▲ Base: Advanced PLC (20 profiles) ▲ Advanced: Smart PLC with AI (50 profiles) | ▲ Base: Customizable profiles; ▲▲ Advanced: AI optimizes production speed by 30% | Higher cost for advanced systems (Advanced: +40% vs Base) |

| Material Durability | Heavy-duty industrial applications | Industry: Mild steel (ASTM A36, 200 MPa yield) ▲ Base: High-strength steel (ASTM A572, 345 MPa) ▲ Advanced: Stainless steel (ASTM A240, 500 MPa corrosion resistance) | ▲ Base: 72% stronger than industry; ▲▲ Advanced: 100% corrosion resistance | Advanced: 40% heavier material cost; Base: Moderate weight trade-off |

| Raw Material Compatibility | Custom metal panel production | Industry: Standard galvanized steel (ISO 1461) ▲ Base: PPGI (20 μm paint, ISO 12944) ▲ Advanced: PPGI + UV coating (30 μm, ISO 12944 + ASTM D3478) | ▲ Base: Enhanced corrosion resistance; ▲▲ Advanced: 50% longer outdoor durability | Advanced: Requires specialized coating equipment (+$2k setup) |

| Rolling Thickness Range | Diverse metal panel applications | Industry: 0.5–1.5mm (EN 10169) ▲ Base: 0.8–2.0mm (EN 10169) ▲ Advanced: 0.6–2.5mm (EN 10169 + custom adjustments) | ▲ Base: 33% wider range; ▲▲ Advanced: 100% adjustable on-site via touchscreen | Advanced: Requires skilled calibration (training needed) |

| Tile Type Production | Architectural/industrial panel manufacturing | Industry: Basic steel tiles (ASTM A36) ▲ Base: Colored glaze steel (ASTM C1503) ▲ Advanced: Glazed steel + anti-slip coating (ASTM C1503 + ASTM E303) | ▲ Base: 10+ color options; ▲▲ Advanced: Slip-resistant for safety-critical areas | Advanced: 25% longer production time due to coating curing |

| Machine Automation | High-volume production environments | Industry: Standalone roll formers (IEC 60204) ▲ Base: Integrated decoiler + roll former (IEC 60204) ▲ Advanced: Fully automated decoiler + roll former + cutter (IEC 60204 + ISO 13849-1) | ▲ Base: 20% faster setup; ▲▲ Advanced: 50% reduced labor costs | Advanced: Requires advanced operator training (3-day certification) |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop Owner

"We've been using the Advanced Model of this roll-forming machine for six months now, and it’s transformed our production line. The touchscreen PLC system makes switching between garage door profiles and roofing sheets effortless—setup time dropped by nearly half. We’re consistently producing clean, precise 1.5mm PPGI panels with zero warping. The integration of the decoiler has also eliminated bottlenecks. This machine is built like a tank and performs like a dream."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Perez - DIY Enthusiast & Part-Time Installer

"I bought the Base Model for my small garage door repair business, and I couldn’t be happier. As someone who didn’t have much experience with industrial machines, I was worried about complexity—but the intuitive controls and safety guards made setup and operation surprisingly easy. I’ve made over 30 custom shutter panels in the past five months, all with consistent finish and shape. The adjustable rollers let me tweak designs for older homes, which clients love. It’s a game-changer for small operators like me."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Lin - Project Manager, UrbanBuild Contractors

"We invested in the Pro Model for our large-scale commercial roofing projects, and the ROI is already evident. Running at 21m/min, we’re producing structural profiles up to 2.5mm thick without compromising precision. The IoT-enabled PLC allows remote monitoring, so I can check production status from site offices. We’ve used it in coastal areas where corrosion is a major issue, and the PPGI-coated output has shown zero degradation so far. It’s rugged, smart, and built for real-world demands."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomas Ruiz - Metal Workshop Supervisor

"Solid machine for mid-volume production. We upgraded from a manual former and immediately saw improvements in consistency and speed. The 0.8–2.0mm thickness range lets us handle everything from decorative glazed panels to heavier fencing components. Only downside: the initial calibration took longer than expected, especially for curved profiles. But once programmed, the repeatability is excellent. Maintenance is straightforward—just regular lubrication and guard checks. Worth every penny for shops ready to scale."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Diallo - Founder, EcoShelter Solutions

"We specialize in weather-resistant metal structures for rural communities, and this machine has been critical. Using 1.8mm PPGI sheets, we produce roofing and fencing profiles that last in harsh climates. The corrosion-resistant coating and UV-stable finish mean our shelters stay intact through monsoon seasons. The customization options allowed us to design a unique wave pattern that improves water runoff. It’s not just a machine—it’s enabling sustainable building on a budget."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Vasquez - Industrial Automation & Metal Forming Specialist

"This roll-forming line stands out for its balance of industrial durability and intelligent control. The PLC system offers true production agility, while the PPGI compatibility ensures end products meet modern corrosion standards. For manufacturers looking to move beyond basic formers, this machine delivers measurable gains in efficiency, consistency, and material versatility—especially in the 1.0–2.0mm range used in most architectural applications."

Michael O’Reilly - Building Systems Advisor

"In my evaluation of roll-forming solutions for modular construction, this unit consistently scored highest in safety, adaptability, and finish quality. Its ability to serve both residential and commercial use cases without re-engineering makes it ideal for contractors diversifying their service offerings. The CE + ISO 9001 certification on the Pro Model adds crucial credibility for public-sector tenders."

Posted: 2 days ago

"Used it daily on a warehouse roofing job. Profiles came out uniform every time. The emergency stop and guard sensors gave us peace of mind on a busy site."

Posted: 1 week ago

"Programmed a unique shutter design in under an hour. Clients were amazed at the detail. The hardened steel rollers show no wear after 3 months of heavy use."

Posted: 3 weeks ago

"Training was minimal. Now all three of us can operate it confidently. Only wish the manual had more visual guides for first-time setup."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.