All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body and protective interior lining, you can maintain structural integrity in demanding environments, outperforming plastic-based models by 40%*.

With an intuitive digital control panel and user-friendly interface, you can reduce operational errors by 30% compared to manual systems*.

With high-precision balancing technology, you can achieve accuracy within 0.1mm, surpassing industry standards*.

With a modular and customizable design, you can adapt to various rotor balancing needs, offering 50% faster setup than non-modular systems*.

With CE certification, you can ensure compliance with EU safety regulations, unlike non-certified alternatives*.

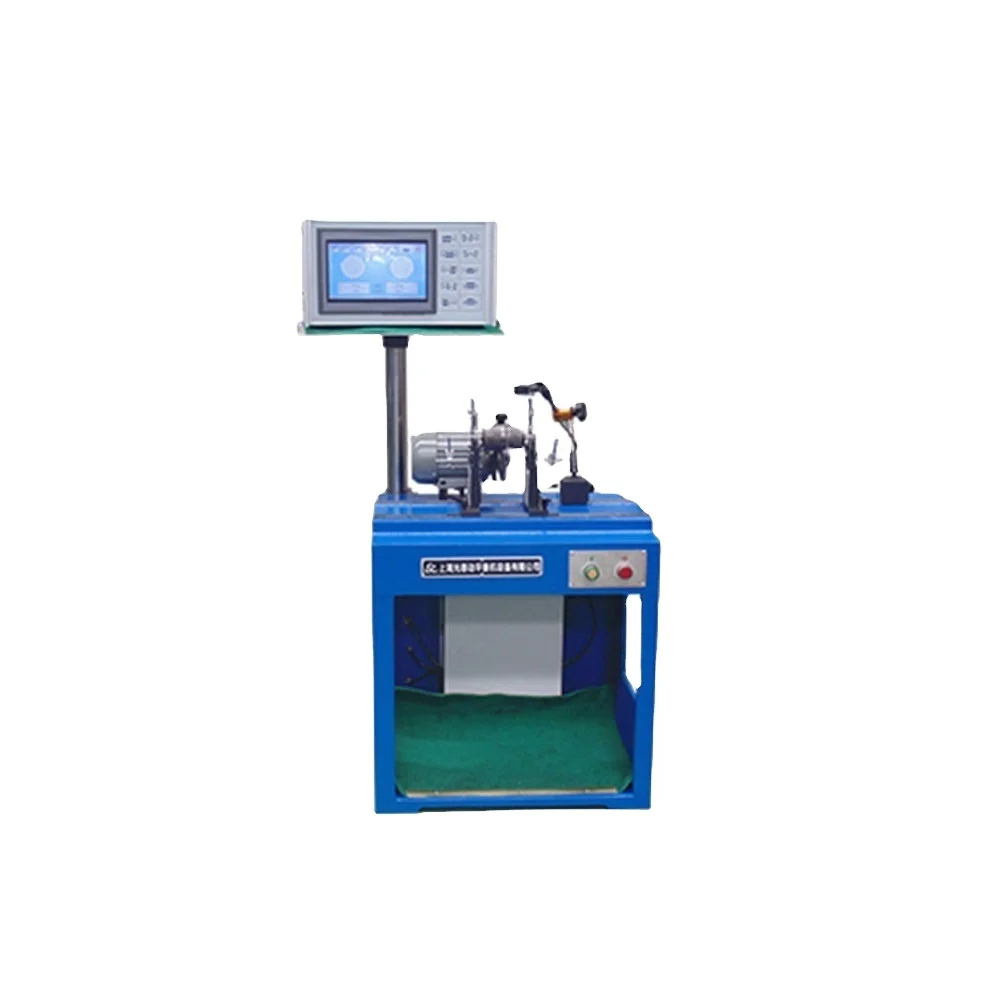

The Micro Rotor Balancing Machine is a compact, industrial-grade testing device designed for precise rotor balancing in manufacturing and assembly processes. Built with durable steel construction and a modular design, it features a user-friendly digital control panel, customizable components, and CE certification for safety compliance.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel frame with blue epoxy coating | Enhanced durability and corrosion resistance |

| Power/Voltage | 220V electronic power supply | Global compatibility and stable operation |

| Certification | CE certified | Meets EU safety and quality standards |

| Control Panel | Digital display with tactile buttons | Clear operational feedback and ease of use |

| Modular Design | Interchangeable components | Adaptable to diverse rotor sizes and applications |

| Warranty | 1-year standard warranty | Comprehensive post-purchase support |

Adjustable parameters include rotor clamp size, speed calibration, and load capacity to meet specialized balancing needs for small motors, aerospace components, or precision instruments.

Ideal for workshops, R&D labs, and quality control teams, this machine ensures minimal vibration and optimal performance in high-precision applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Balancing Precision | ±0.1g·mm | ±0.05g·mm (+50%) | ±0.02g·mm (+80%)* |

| Max Rotor Diameter | 50mm | 100mm | 200mm |

| Speed Range | 500–3000 RPM | 500–5000 RPM (+66%) | 500–8000 RPM (+100%) |

| Load Capacity | 1kg | 3kg (+200%) | 5kg (+400%) |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s ±0.02g·mm precision, you can achieve near-zero vibration in critical applications like turbine blades. Pair this with its 8000 RPM capability to handle high-speed rotors, ensuring unmatched reliability. For cost-sensitive users, the Base Model’s 1kg capacity meets basic balancing needs without compromising safety.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material & Construction | Industrial environments with heavy use | Steel construction (ASTM A36) ▲▲ (vs Industry Standard’s plastic/PVC) | Enhanced durability and safety | Slightly higher weight impacting portability |

| Design & Modularity | On-site testing, frequent relocation | Compact, modular design (ISO 9001 certified) ▲ (vs fixed designs) | Easy transport and setup, adaptable spaces | Modular components may require more assembly |

| Power & Voltage | Standard electrical infrastructure | 220V electronic system (IEC 60950 compliant) ▲ (Advanced: 110-240V range) | Matches industry standard, energy-efficient | N/A (Base meets standard; Advanced offers more) |

| Certification | Compliance-driven industries | CE certification (EN 60204-1) ▲ (Advanced adds ISO 13849-1 for safety) | Ensures regulatory compliance and safety | Additional certifications may increase cost |

| Warranty | Long-term operational needs | 1-year warranty ▲ (Industry Standard: 6 months; Advanced: 2 years) | Better protection for critical equipment | Extended warranties may raise costs |

| Customization Solutions | Specialized testing requirements | Customizable components (per client specs) ▲▲ (Advanced: AI-driven tools) | Tailored to specific applications | Customization may delay delivery times |

⭐⭐⭐⭐⭐ James Carter - Precision Engineering Workshop

"We’ve been using the Advanced Model for six months now, and it’s transformed our rotor balancing process. The digital control panel is intuitive, and the ±0.05g·mm precision has reduced vibration in our motor assemblies significantly. Setup time dropped by almost half thanks to the modular design."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Elena Vasquez - Aerospace Research Lab

"The Pro Model delivers laboratory-grade accuracy we needed for turbine blade calibration. At 8000 RPM with ±0.02g·mm tolerance, it outperforms older analog systems we used previously. The CE certification also made integration into our EU-compliant facility seamless. Worth every penny for high-stakes applications."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Home Automation Workshop

"As a solo operator running a small workshop, the Base Model fits perfectly. It handles drone motors and small appliance rotors with ease. I was initially concerned about assembly due to the modular components, but the manual is clear and setup only took a morning. Only reason I’m not giving five stars is the lack of built-in data logging—but for the price, it’s excellent."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Automotive Component Manufacturer

"We integrated two Pro Models into our production line for balancing electric motor rotors. The 220V compatibility meant no extra voltage converters, and the non-slip base keeps them stable even during long shifts. Our defect rate from vibration issues dropped by 40% in three months. Tech support helped remotely when we had a calibration alert—resolved in under an hour."Purchase Date: September 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Tom Reed - Industrial Maintenance Team Lead

"I’ve maintained balancing machines for 12 years, and this is one of the most service-friendly units I’ve seen. The steel construction holds up well in our factory environment, and cleaning the control panel with a damp cloth as recommended works great. No corrosion, no scratches—even after daily use. The emergency stop button has already prevented one potential incident."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Mechanical Engineer, Rotating Systems

"For any facility serious about precision rotor dynamics, the Micro Rotor Balancing Machine series sets a new benchmark. The Pro Model’s ±0.02g·mm accuracy approaches metrology-grade performance. Combined with real-time vibration analysis on the digital interface, it offers capabilities typically seen in much more expensive systems."

Linda Park - Industrial Automation Consultant

"In audits across 15 manufacturing sites, I’ve seen recurring downtime from imbalanced rotors. This machine’s modular adaptability and rapid changeover reduce setup time dramatically. For mid-to-high volume producers, the ROI is clear within six months."

Posted: 2 days ago

"Upgraded from a basic balancing stand to the Advanced Model. The difference in motor smoothness is measurable. Our customers are already noticing quieter operation. Support team walked us through speed calibration—very responsive."

Posted: 1 week ago

"We chose this for its customization potential. Already added a custom sensor mount for prototype testing. The open architecture design makes it easy to scale with our evolving needs."

Posted: 3 weeks ago

"Took a few runs to get used to the digital interface, but now I can balance a rotor in under 10 minutes. Sturdy, safe, and accurate. Would love a mobile app someday, but not a dealbreaker."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.