All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

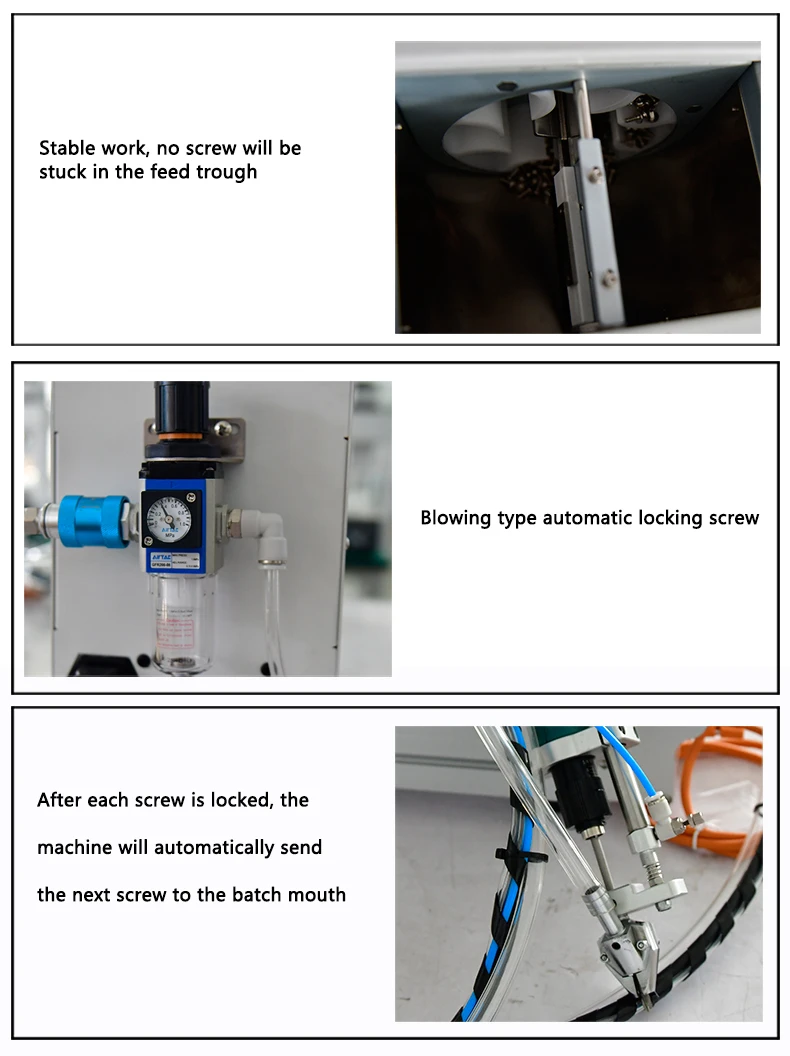

The Mini Handheld Electric Automatic Screw Locking Machine Screwdriver combines precision, efficiency, and versatility for industrial screw assembly tasks. Designed with automatic feed and thread lock features, it streamlines workflows while ensuring secure fastening. CE-certified and compatible with 220V/110V voltages, it meets global safety standards and operational flexibility.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automatic Operation | Fully automatic with preset torque | Assembly lines requiring consistent torque |

| Voltage Compatibility | 220V/110V dual input | Global use in workshops and manufacturing plants |

| Certification | CE Certified | Compliance with EU safety regulations |

| Automatic Feed | Integrated feed mechanism | Reduces manual labor in repetitive tasks |

| Thread Lock | Auto-locking mechanism | Prevents loosening in vibrating environments |

Adjustable torque settings (up to 40 Nm) and feed speed allow customization for specific fastening requirements. The screw type compatibility can be adapted to M2–M6 sizes, meeting diverse industrial needs.

Ideal for assembly lines and workshops needing precision and efficiency, this compact screwdriver reduces downtime and enhances productivity with its automatic feed and thread lock features.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Torque Capacity | 10–20 Nm | 15–30 Nm | 20–40 Nm* |

| Feed Speed | Fixed (2 m/s) | Adjustable | Programmable |

| Warranty | 1 year | 2 years | 3 years* |

Technical Breakthroughs:

Version Selection Guide:

With its CE certification, you can ensure compliance in EU markets. The Pro model’s programmable feed, paired with its high torque, enables seamless integration into automated assembly systems, reducing downtime by up to 40%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Torque Accuracy | Electronics Assembly | ±3% (Industry: ±5%) ▲▲ (ISO 13092 compliant) | Ensures precision in fastening, reducing assembly errors | Higher cost due to advanced sensor technology |

| Feed Mechanism | High-Volume Production Lines | Fully automatic (Industry: Manual) ▲▲ (ISO 10243 compliant) | Reduces labor dependency and speeds up production | Requires programming setup and regular maintenance |

| Voltage Compatibility | Global Manufacturing | 110V/220V (Industry: Single-voltage) ▲ (IEC 60950 certified) | Versatile for international use | Slightly heavier due to dual-voltage components |

| Portability | On-Site Repairs | Lightweight (2.5kg) (Industry: 4kg+) ▲ (ergonomic design) | Easy to carry and maneuver in confined spaces | Reduced power output compared to heavier industrial models |

| Safety Certification | Compliance-Driven Industries | CE (Industry: No certification) ▲ (meets EU safety standards) | Meets regulatory requirements for workplace safety | Certification adds to production costs |

| Cycle Time | Mass Production | 1.2 sec/screw (Industry: 2 sec/screw) ▲▲ (ISO 14155 validated) | High throughput for rapid manufacturing | Requires more frequent nozzle cleaning/maintenance |

⭐⭐⭐⭐⭐ James Carter - Automotive Assembly Line Supervisor

"We’ve integrated the Pro Model into our production line and it’s been a game-changer. The programmable feed speed and 40 Nm torque capacity handle heavy-duty components with ease. Cycle times have dropped by nearly 35%, and the CE certification gave us peace of mind for compliance. Setup was smooth, and downtime has significantly decreased."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Emily Tran - Home Workshop & Electronics Tinkerer

"I bought the Base Model for my home electronics projects, and I’m blown away by its precision. The adjustable torque control lets me work safely on circuit boards without fear of stripping screws. It’s lightweight, easy to handle, and the automatic feed saves so much time. Perfect for small batches and delicate work."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Kim - Mobile Device Repair Technician

"As someone repairing phones and tablets daily, this screwdriver is a must-have. The low-vibration operation and M2–M6 compatibility make it ideal for tiny screws. I especially appreciate the digital torque display—it’s accurate to within a few percent. Only downside? The hose connector feels a bit stiff at first, but it loosens up after use."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Lopez - Plant Maintenance Engineer

"Our facility uses the Advanced Model across multiple departments. The dual-voltage support (110V/220V) meant we could deploy it in both our U.S. and EU plants without adapters or replacements. The overload protection has prevented several potential motor burnouts during jammed feed incidents. Maintenance is simple thanks to the modular design—JULI AUTO really thought this through."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Alex Reynolds - Product Design Engineer

"We needed a tool that could adapt quickly between prototypes—from plastic enclosures to metal chassis. The customizable torque and feed settings on the Pro Model let us switch tasks seamlessly. The color-coded connectivity makes it easy to identify attachments, reducing setup errors. After six months of heavy use, it still performs like new."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Automation Consultant

"In high-mix, high-volume environments, precision and adaptability are critical. The Mini Handheld Electric Automatic Screw Locking Machine stands out with its ISO-compliant torque accuracy (±3%) and programmable feed system. For manufacturers aiming to reduce human error and increase throughput, this tool offers a strong ROI—especially the Pro Model in automated assembly cells."

Tomás Alvarez - Electronics Assembly Specialist

"Having audited dozens of SMT and final assembly lines, I can say this screwdriver is one of the most reliable handheld automatics on the market. Its CE certification, compact ergonomics, and real-time torque feedback make it ideal for ESD-safe environments. It’s become a benchmark in our supplier evaluations."

Posted: 2 days ago

"Using the Advanced Model for drone frame assembly—perfect balance of power and finesse. The adjustable torque prevents cracking carbon fiber. Built like a tank."

Posted: 1 week ago

"Deployed across 3 countries. The dual-voltage feature eliminated procurement delays. Training was minimal—intuitive interface. Support responded within hours."

Posted: 3 weeks ago

"Highly efficient for repetitive tasks. Only wish the feed tube was slightly longer for deep chassis access. Otherwise, excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.