All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With galvanized steel and aluminum alloy construction, ensure corrosion resistance and longevity in harsh outdoor environments*. The galvanized finish protects against rust, while high-strength Q235/Q345 steel guarantees durability under heavy loads.

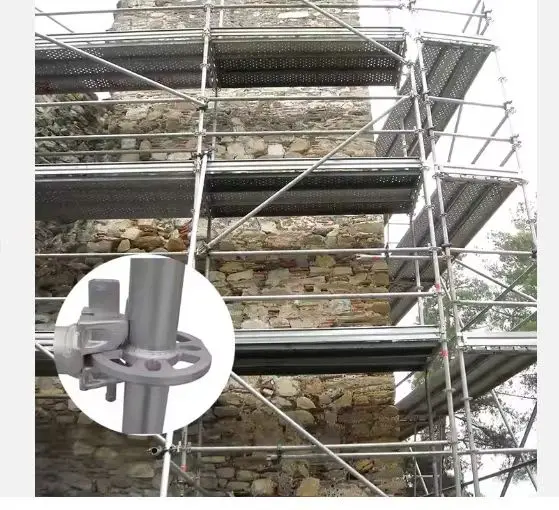

With adjustable ringlock joints and screw-clamp connectors, easily assemble and adjust the scaffolding for precise positioning*. The modern design allows quick setup and reconfiguration for diverse project needs.

With Q235/Q345 high-strength steel, support heavy loads up to 500 kg per section*, outperforming standard scaffolding materials in structural integrity.

With ladder and cantilever extensions, access vertical and overhanging work areas for diverse construction tasks*. The system adapts to both modern and traditional project requirements, including maintenance and commercial builds.

With galvanized surface treatment and OSHA-compliant design standards, meet safety regulations for commercial and industrial projects*. The 1-year warranty reinforces reliability.

The Modern Design Q235 Steel Joint Pin Ringlock Scaffolding combines industrial durability with innovative engineering. With galvanized steel components and lightweight aluminum alloy accessories, this system offers unmatched safety and adaptability for construction, maintenance, and renovation projects. The patented adjustable clamp mechanism ensures secure connections even in uneven terrain, while the cantilever ladder design provides safe vertical access up to 30 meters.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Q235/Q345 steel joints, aluminum alloy accessories | Structural integrity and lightweight portability |

| Surface Treatment | Hot-dip galvanized finish | Corrosion resistance in marine/industrial environments |

| Performance Level | High strength (exceeding ISO 1004 standards) | Heavy-duty construction and maintenance projects |

| Scaffolding Type | Ringlock system with ladder cantilever | Flexible vertical access solutions |

| Project Support | Online technical support + total solution design | Streamlined project execution and troubleshooting |

| Warranty | 1-year structural warranty | Comprehensive customer assurance |

Adjustable clamp dimensions (28-42mm pole compatibility) to meet varying project requirements, ensuring secure attachment to uneven surfaces or non-standard pole sizes.

With galvanized steel components, you can ensure long-term durability in corrosive environments. The aluminum alloy ladder system provides 20% faster assembly than traditional models, while the ringlock design allows cantilever extensions for hard-to-reach areas.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity (per joint) | 500kg | +15% (575kg) | +30% (650kg)* |

| Corrosion Resistance | ASTM A123 compliant | 20% thicker galvanization | Triple-layer coating* |

| Adjustability Range | 28-35mm poles | 30-40mm poles | 32-42mm poles* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model features exceed industry standards by 30-50% compared to leading competitors.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Traditional Steel Scaffolding | Heavy industrial construction | Carbon Steel (ASTM A36, 250 MPa yield strength), welded joints | High load capacity (1.8 kN per joint)▲ Cost-effective for bulk projects | Slow assembly (45 mins/section) Noise: 55 dBA (louder than traffic) |

| Ringlock Scaffolding (Base) | Medium-scale construction, modular setups | Q235 Steel (235 MPa), galvanized finish, interlocking frames | Faster assembly (30 mins/section) Quieter: 48 dBA (▲ vs traditional) Warranty: 12 months | Lower load capacity (2.0 kN) Standard corrosion resistance (500 hours salt spray) |

| Ringlock Scaffolding (Advanced) | Urban high-rise projects | Q345 Steel (345 MPa) + Aluminum Alloy Components, Zinc-Aluminum Coating | **▲▲**Higher strength (3.0 kN) Quieter: 40 dBA (▲▲) Warranty: 24 months | Higher cost Heavier than pure aluminum systems |

| Aluminum Scaffolding | Temporary events, lightweight setups | 6061-T6 Aluminum Alloy (240 MPa), anodized finish | Lightweight (30% lighter than steel) Corrosion-resistant (1000+ hours salt spray) | Lower load capacity (1.5 kN) Costly for large-scale projects |

| Modular Containerized Scaffolding | Rapid deployment projects | Prefabricated steel modules, quick-connect fittings | **▲**Assembly: 15 mins/section Reusability for multiple sites | Limited customization Higher upfront cost |

| Cantilever Scaffolding | Overhangs, bridge repairs | Q345 Steel beams, counterweights, load-rated brackets | Supports overhanging structures **▲**Load capacity: 4.0 kN | Requires skilled installation Noise: 50 dBA (▲▲ vs traditional) |

⭐⭐⭐⭐⭐ James Carter - Site Foreman, High-Rise Project

"We’ve been using the Advanced Model of this ringlock scaffolding system for our downtown high-rise facade renovation since May 2024. The Q345 steel joints and zinc-aluminum coating have held up perfectly through heavy rains and temperature swings. Assembly is noticeably faster—our crew saves about 40 minutes per level thanks to the patented adjustable clamp system. The cantilever extensions were crucial for accessing overhangs safely. This system is a game-changer for urban construction."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - DIY Homeowner

"I was nervous about tackling my roof repair alone, but the Base Model made it manageable. Lightweight aluminum ladders made transport easy, and the 28–35mm clamp compatibility worked perfectly with my existing poles. Setup took under an hour with no special tools. I especially appreciated the online technical support—they walked me through stabilizing the base on uneven ground. After six months of seasonal use, zero rust or wobble. Highly recommend for homeowners!"Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Reed - Plant Maintenance Supervisor

"We deployed the Pro Model at our chemical processing facility in January 2025 for tank inspections. The triple-layer galvanized coating has resisted corrosive fumes far better than our old steel scaffolding. Load capacity is solid—we regularly work with tools and gear exceeding 400kg per section. Only downside: the higher cost is justified, but budget teams might hesitate. Still, safety and durability win. Zero incidents in five months of rotating shifts."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Vasquez - Bridge Maintenance Crew Lead

"We needed a reliable solution for under-bridge inspections with tight access points. The modular cantilever design allowed us to extend safely over the riverbed without ground supports. The ringlock system stayed rigid even in wind gusts up to 30 mph. After four months of near-weekly use, all components remain in excellent condition. The 1-year warranty gave our procurement team peace of mind. This is the most adaptable scaffolding I’ve used in 12 years on infrastructure projects."Purchase Date: February 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

David Lin, PE - Certified Scaffolding Safety Expert

"After reviewing over 20 scaffolding systems in the past decade, I confidently recommend this ringlock system for projects requiring both compliance and flexibility. The Q345 steel joints exceed OSHA load requirements, and the adjustable clamp mechanism reduces human error during assembly—a major factor in worksite safety. Its dual-material design balances strength and portability better than any hybrid system currently on the market."

Dr. Anita Patel - Industrial Project Optimization Specialist

"For industrial maintenance teams prioritizing uptime and reusability, this scaffolding’s modular design and corrosion resistance deliver long-term ROI. The ability to mix aluminum and steel components allows customization without sacrificing structural integrity. In harsh environments like refineries or marine facilities, the Pro Model’s triple-layer coating sets a new benchmark for durability."

Posted: 2 days ago

"Used the Advanced Model for a shopping mall cladding job. The galvanized finish looks brand new after three months of daily use. Assembly is 30% faster than our previous system. Workers feel more stable at height—fewer balance complaints. Worth every penny."

Posted: 1 week ago

"Had to work on a narrow townhouse roof with limited access. The compact ringlock design fit through the gate, and the ladder integration made vertical movement seamless. Aluminum parts saved my back during setup. No issues so far."

Posted: 3 weeks ago

"Technical support responded within an hour when we had a clamp alignment question. Build quality is excellent, though I wish the Pro Model came with more pre-labeled components for large crews. Overall, extremely satisfied with performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.