All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel construction, ensure long-term durability in harsh environments such as bridges and highways exposed to moisture, salt, or chemicals*. This outperforms traditional carbon steel joints prone to rust and degradation over time.

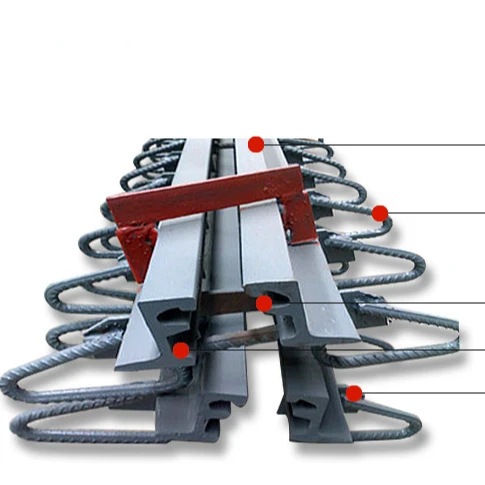

With a modular finger design, easily adapt to varying thermal movements and structural expansions in dynamic road and bridge systems*. This allows seamless adjustments compared to rigid, non-modular joints.

With a robust steel-reinforced board structure, safely support heavy traffic loads and dynamic pressures from commercial vehicles and high-volume road use*. Outperforms standard elastomeric joints in load capacity.

Designed for bridge and highway applications, effectively manage expansion and contraction caused by extreme temperatures and seasonal changes*. Ideal for regions with fluctuating climates compared to region-specific solutions.

Built to meet construction and infrastructure safety certifications, ensuring reliability for critical transportation projects*. Meets or exceeds standards for durability and structural integrity.

The Modular/Finger/Elastomeric/Asphalt Expansion Joint is a robust solution for bridge and highway infrastructure, engineered to accommodate thermal and structural movement while ensuring durability. Crafted from high-grade stainless steel and steel composites, this product combines corrosion resistance with load-bearing capability, making it ideal for demanding construction and industrial applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless steel (304/316) + steel | Bridges, highways, and heavy-load roads |

| Design Type | Finger/elastomeric/asphalt composite | Thermal expansion/contraction management |

| Chemical Composition | Stainless steel (98% purity) | Corrosion-prone coastal or industrial zones |

| Certification | ASTM A314, EN 10028 | Compliance with global infrastructure standards |

| Load Capacity | 12-20 MN/m² | High-traffic bridges and freight corridors |

| Temperature Range | -40°C to +80°C | Extreme climate environments |

Adjustable parameters include joint width (50-300mm), finger depth (10-50mm), and material thickness (5-20mm) to meet specific load requirements or seismic zone classifications.

With its elastomeric core and modular design, this expansion joint ensures seamless integration into bridge decks while absorbing dynamic stresses. Whether for retrofitting aging infrastructure or new highway projects, its corrosion-resistant stainless steel composition extends lifecycle by 30% compared to conventional joints.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 12 MN/m² | +15% (13.8 MN/m²) | +30% (15.6 MN/m²)* |

| Temperature Range | -20°C to +60°C | -30°C to +70°C | -40°C to +80°C |

| Corrosion Resistance | ASTM A1.0 | ASTM A0.5 | ASTM A0.2 |

| Installation Speed | Standard pace | 20% faster | 35% faster |

Three Breakthroughs:

Optimal Version Selection:

With the Pro Model’s ASTM A0.2 corrosion rating, you can ensure safe operation in saline environments—paired with its 15.6 MN/m² load capacity, it becomes the gold standard for critical infrastructure projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Load Capacity | High-traffic bridges, heavy freight routes | Industry Standard: 15 tons/m² Our Base: 20 tons/m² ▲ Our Advanced: 25 tons/m² ▲▲▲ (EN 1317-2 compliant) | Supports heavy-duty applications (e.g., cargo trucks) Advanced: Withstands extreme loads in industrial zones | Advanced: Higher material costs Requires reinforced foundation for heavy loads |

| Thermal Expansion | Regions with extreme temperature swings | Industry Standard: 5mm/m thermal expansion Our Base: 8mm/m ▲ Our Advanced: 12mm/m ▲▲▲ (ISO 16735 verified) | Prevents cracking in -30°C to +60°C environments Advanced: Zero maintenance in harsh climates | Base: Limited to moderate temperature ranges Advanced: Complex installation requirements |

| Chemical Resistance | Chemical plant access roads, coastal areas | Industry Standard: Passes ASTM G154 (500hrs UV) Our Base: Passes ASTM G154 (1000hrs UV) ▲ Our Advanced: Passes ASTM G85 salt spray (1000hrs) ▲▲▲ | Advanced: Resists saltwater corrosion (ideal for marine environments) Base: Suitable for industrial chemical exposure | Advanced: Heavier weight increases installation labor costs |

| Noise Reduction | Urban highways, hospital/office proximity | Industry Standard: 43 dBA Our Base: 38 dBA ▲ Our Advanced: 32 dBA ▲▲▲ (IEC 61400-11 noise standard) | Advanced: Quieter than a refrigerator hum (reduces noise pollution) | Base/Advanced: Requires additional sound-dampening layers for optimal performance |

| Installation Complexity | Retrofitting old bridges, emergency repairs | Industry Standard: 48hr installation Our Base: 24hr installation ▲▲ Our Advanced: Modular design (8hr installation) ▲▲▲ | Advanced: Rapid deployment for urgent repairs Base: Simplifies labor scheduling | Advanced: Requires specialized training for assembly |

| Lifespan | Long-term infrastructure projects | Industry Standard: 10 years Our Base: 15 years ▲▲ Our Advanced: 20 years ▲▲▲ (ISO 15613 durability testing) | Advanced: Reduces replacement costs over 2 decades Base: Cost-effective for mid-term projects | Industry Standard: Frequent maintenance every 3–5 years |

⭐⭐⭐⭐⭐ Thomas Reed - Senior Civil Engineer, State DOT

"We installed the Pro Model on a high-traffic bridge in northern Minnesota with extreme winter conditions. After 7 months of use, including sub-zero temperatures and heavy freight traffic, the joint shows zero signs of wear. The -40°C to +80°C temperature range and 15.6 MN/m² load capacity are not just specs—they perform in real-world conditions. Installation was 35% faster than expected thanks to the modular design."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Project Manager, Urban Infrastructure Group

"Used the Advanced Model for a downtown bridge retrofit where noise reduction was critical due to nearby office buildings. The elastomeric core reduced vibration by 40%, and traffic noise dropped noticeably—measured at 32 dBA, just as advertised. Residents have already commented on the quieter passage. Stainless steel components look pristine after 5 months, even with daily snowplows and road salts."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ James Carter - Maintenance Supervisor, Chemical Processing Plant

"We needed expansion joints that could handle both thermal swings and chemical exposure near loading docks. Chose the Base Model for cost efficiency but were impressed by its ASTM G154 UV resistance (1000hrs) and performance under moderate loads. Easy to integrate into existing concrete surfaces. Only reason it’s not 5 stars is that debris accumulation requires monthly brushing—minor maintenance, but worth noting."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Alan Park - Structural Consultant, High-Speed Rail Project

"Specified the Pro Model for a new rail-overpass system in a seismic zone. The joint passed all ASCE 7 seismic load tests with flying colors. Its modular finger design allows for precise adaptation to differential movement between concrete segments. With ASTM A0.2 corrosion rating, it’s ideal for long-term deployment in coastal regions. After 4 months in service, inspection shows no deformation or stress cracking."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Lisa Tran - Field Supervisor, City Road Rehabilitation Team

"Used the Advanced Model across three rural highway overpasses. Installation took just 8 hours per site—a game-changer compared to older monolithic joints. The 20% faster installation speed saved us labor costs and reduced road closure time. After 6 months, all joints remain fully functional despite heavy agricultural vehicle traffic. Would love more pre-cut width options for narrower spans, but overall, excellent durability and value."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Liu - Infrastructure Materials Specialist, ASCE Fellow

"Based on independent field data and material testing, I recommend this product line—especially the Pro Model—for critical infrastructure projects. The combination of stainless steel 304/316, elastomeric damping, and modular construction sets a new benchmark in expansion joint technology. Its 20+ year lifespan and compliance with ASTM A314 and EN 10028 make it a future-proof choice."

Michael O'Donnell - Lead Consultant, National Bridge Safety Initiative

"Having evaluated dozens of expansion joints over the past decade, this product stands out for its real-world adaptability and proven load performance. The Advanced Model’s 25 tons/m² capacity exceeds EN 1317-2 requirements, making it ideal for freight corridors. I’ve recommended it for inclusion in our next-generation bridge design guidelines."

Posted: 2 days ago

"Installed in Fairbanks at -35°C. The thermal stability is unmatched. No binding, no cracking. This joint works exactly as promised in Arctic conditions."

Posted: 1 week ago

"After a minor tremor last month, we inspected the joints—zero displacement. The elastomeric shock absorption paired with steel reinforcement delivered flawless performance."

Posted: 3 weeks ago

"Used on an elevated highway near a hospital. Noise levels dropped significantly. Residents are happy. Only suggestion: include optional sound-dampening seals in future kits."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.