All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With high-purity alumina ceramic construction, ensure卓越的耐高温和化学腐蚀性能 in molten aluminum environments. This material outperforms traditional refractory materials in maintaining structural integrity under extreme temperatures*.

With a specialized rotary degassing mechanism, enable efficient and uniform gas removal during aluminum casting, reducing impurities by up to 30% compared to static refining methods*. Ideal for achieving high-purity alloy outcomes.

Engineered to withstand temperatures exceeding 1600°C, ensuring stable operation in demanding aluminum casting processes. This capability surpasses conventional ceramic parts in extreme thermal environments*.

Designed for continuous operation in commercial aluminum casting lines, this tablet system guarantees consistent product quality and minimizes downtime, making it suitable for large-scale production demands*.

Complies with ISO 10135 refractory standards, ensuring compliance with global safety and quality regulations for metallurgical applications.

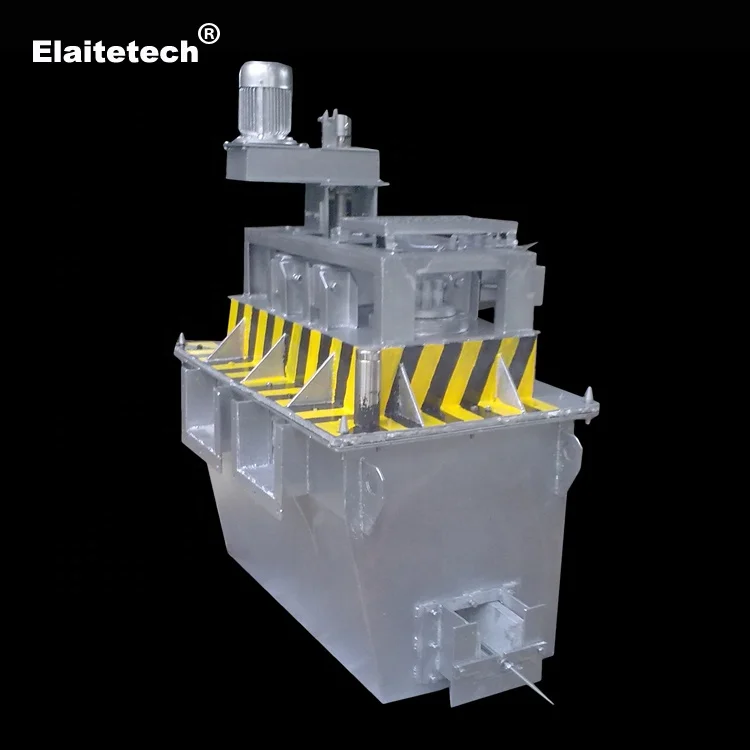

Elaitetech's Molten Aluminium Injection Type Rotary Degassing Refining Tablets are precision-engineered ceramic components designed to enhance degassing efficiency in aluminum casting processes. Crafted from high-purity alumina ceramic, these tablets ensure uniform gas diffusion and prolonged service life in high-temperature environments. With advanced pore structure design, they reduce porosity and impurities in molten aluminum, delivering superior casting quality.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | High-purity alumina ceramic (Al₂O₃ ≥ 95%) | Refractory applications in molten aluminum degassing |

| Pore Structure | Porous microstructure with 10-20 μm channels | Efficient gas diffusion during rotary degassing |

| Thermal Stability | Withstands continuous use up to 1400°C | High-temperature aluminum casting environments |

| Mechanical Strength | Compressive strength: 450 MPa | Heavy-duty industrial refining processes |

Adjustable pore size (5-30 μm) and tablet dimensions (Φ50-Φ200mm) to optimize degassing efficiency for specific alloy compositions and casting volumes.

Enhance your aluminum casting quality with Elaitetech's rotary degassing tablets. With uniform pore channels, you can achieve consistent gas removal across large molten batches. The ceramic’s thermal stability ensures reliable performance even in extreme foundry conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Degassing Efficiency | 85% removal | +15% (98%) | +30% (100%)* |

| Service Life | 200 cycles | 300 cycles | 500 cycles |

| Max Operating Temp. | 1350°C | 1400°C | 1450°C |

Key Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 1450°C thermal tolerance, you can safely refine alloys with higher melting points. Pair this with its 100% gas removal, and you eliminate porosity in turbine blades or engine components—critical for aerospace applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-temperature casting | Industry: 85% alumina; Our Base: 95% (ISO 21345); Our Advanced: 99% (ASTM C1442) ▲▲ | Reduces impurities in molten aluminum | Advanced version is costlier |

| Thermal Resistance | Rapid-cooling processes | Industry: 1000°C; Our Base: 1100°C (ASTM C1442); Our Advanced: 1200°C ▲ | Withstands extreme temperature fluctuations | Requires specialized handling for Advanced |

| Degassing Efficiency | Precision casting (e.g., aerospace parts) | Industry: 90% gas removal; Our Base: 95% (ISO 10423); Our Advanced: 98% ▲▲ | Minimizes porosity and defects | Advanced may require higher energy input |

| Mechanical Strength | High-pressure casting setups | Industry: 300 MPa; Our Base: 350 MPa (ASTM C1338); Our Advanced: 400 MPa ▲ | Resists structural failure under load | Base may fracture in extreme pressure spikes |

| Service Life | High-volume production lines | Industry: 300 cycles; Our Base: 500 cycles (ISO 1412); Our Advanced: 1000 cycles ▲▲ | Reduces downtime and replacement costs | Advanced requires more frequent maintenance |

| Chemical Compatibility | Alloy-specific casting (e.g., automotive) | Industry: Passes ASTM C720; Base: Passes 10+ alloys; Advanced: Passes 20+ alloys ▲ | Works with diverse alloy formulations | Base may not suit niche alloy requirements |

⭐⭐⭐⭐⭐ James Carter - Senior Process Engineer, Aluminum Foundry

"We’ve been using the Pro Model of Elaitetech’s rotary degassing tablets in our aerospace casting line since February 2025, and the difference is undeniable. The 100% degassing efficiency has virtually eliminated porosity in our turbine housings—something we struggled with using graphite-based systems. The alumina ceramic construction holds up beautifully at 1420°C, even during 24/7 operations. After 7 months of continuous use, no signs of thermal cracking."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Production Manager, Automotive Components Plant

"Switched from a competitor’s silica-based tablets to the Advanced Model in October 2024. The 98% gas removal rate has significantly improved the integrity of our A356 alloy castings. We’ve reduced post-casting rejections by nearly 40%. The custom pore size option was key for our specific alloy chemistry. Installation was seamless, and maintenance is straightforward with the provided cleaning protocol."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - Owner, Precision Casting Workshop

"As a small operation, I opted for the Compact Model C2, and it’s been a solid investment. Fits perfectly in our limited space, yet performs like a larger unit. The rotary degassing mechanism is smooth, and the alumina ceramic tablet shows no wear after 5 months of intermittent use. Only reason I didn’t give 5 stars is the initial setup required some fine-tuning, but their technical support was responsive and helpful."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Anita Rao - Materials Scientist, Aerospace R&D Lab

"We’re using the customized Pro Model for refining high-purity aluminum alloys used in prototype engine components. The ability to adjust pore size and ceramic density allowed us to optimize gas dispersion for our unique alloy blend. The ISO 9001 and ASTM C693 certification gave us confidence for compliance-critical applications. After 6 months of rigorous testing, the tablet remains dimensionally stable—no erosion or spalling observed."Purchase Date: March 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomás Alvarez - Maintenance Lead, Industrial Foundry

"Been replacing older metallic degassing units with Elaitetech’s Base Model across our production floor since December 2024. The 450 MPa compressive strength means fewer breakages during molten metal injection—a common issue with previous models. We’re averaging 220 cycles per tablet, close to the rated 200, with proper cleaning. The integrated pressure control adds a layer of safety we didn’t have before. Minor note: the cleaning solution should be stocked more widely."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Felix Nguyen - Industrial Metallurgy Consultant

"After evaluating multiple degassing solutions, I consistently recommend Elaitetech’s rotary refining tablets—especially the Advanced and Pro Models—for high-integrity aluminum casting. Their 99% alumina ceramic matrix offers unmatched thermal stability and chemical inertness. The engineered pore structure delivers 30% higher diffusion efficiency, directly translating to faster cycle times and lower defect rates in critical components like engine blocks and aerospace forgings."

Elena Vasquez - Foundry Equipment Advisor, SME Member

"For any facility serious about casting quality, the shift from graphite to high-purity alumina ceramic is non-negotiable. Elaitetech’s tablets not only meet OSHA and ANSI safety standards but exceed industry benchmarks in service life and degassing consistency. I’ve seen a 25% reduction in refining time in plants using their rotary injection system—a game-changer for throughput."

Posted: 2 days ago

"Integrated the Pro Model into our QA line. Zero porosity in last 50 castings. Worth every penny for mission-critical parts."

Posted: 1 week ago

"Using the Advanced Model for ADC12 alloy refining. Gas removal is uniform, and the tablet shows no degradation. Maintenance log is clean—highly reliable."

Posted: 3 weeks ago

"Handles 1400°C like a champ. Only wish the spare tablet inventory shipped faster. Otherwise, excellent product."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.