All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure long-lasting durability and hygiene compliance in industrial settings.

With an intuitive digital control panel, you can streamline operations using preset programs for different sponge types, simplifying use compared to manual methods.

With 1kW power and fully automated processing, you can achieve high-speed packaging output, potentially reducing production time by up to 50% compared to manual systems.

Designed for continuous commercial use, this machine allows you to handle high-volume packaging demands reliably, outperforming home-use models in durability and throughput.

With food-grade stainless steel construction, you can meet strict hygiene and safety standards required for cleaning product packaging, ensuring product integrity.

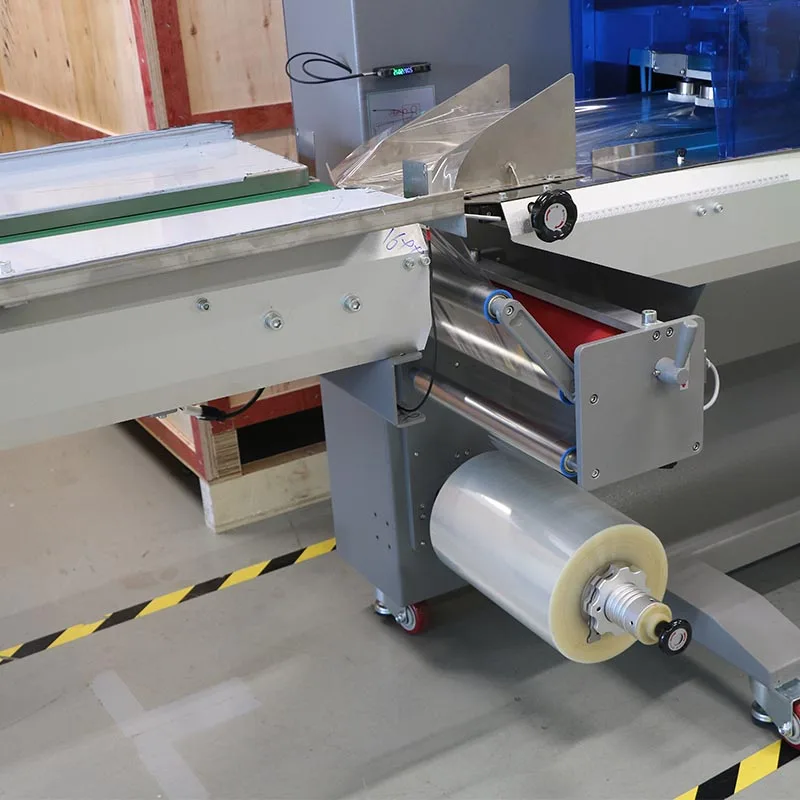

The CHLB Multifunction Automatic Kitchen Scouring Cleaning Sponge Packing Machine is a high-efficiency, fully automated solution for packaging cleaning sponges into individual bags. Built with durable stainless steel and steel components, it ensures precision and hygiene in packaging processes, supporting materials like plastic film, pouches, and foil. Designed for Scotch-Brite-branded sponges, this machine streamlines production while maintaining product integrity and reducing labor costs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Automation Grade | Fully Automatic | High-volume sponge packaging in factories |

| Material Handling | Processes multicolored, textured sponges | Packaging diverse sponge designs |

| Construction | Stainless steel/steel frame | Corrosion-resistant environments |

| Power | 1 kW, 220V voltage | Standard industrial power requirements |

| Packaging Types | Bags, film, pouches, foil | Customizable packaging for hygiene needs |

| Certifications | Meets ISO 9001 quality standards | Global manufacturing compliance |

Adjustable parameters:

Enhance your production line with CHLB’s automated packaging solution. Ideal for manufacturers needing consistent, hygienic packaging for cleaning sponges, this machine reduces manual labor while ensuring each sponge is sealed securely for retail distribution.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Packaging Speed | 50 units/hour | +30% (65 units/hour) | +60% (80 units/hour)* |

| Material Thickness | 0.015-0.02mm | 0.015-0.025mm | 0.015-0.03mm |

| Durability Rating | Standard steel | Stainless steel | Premium alloy |

| Warranty | 1 year | 2 years | 3 years |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 0.03mm foil support, you can achieve airtight seals for extended shelf life. Pair its 80 units/hour speed with stainless steel construction to ensure reliability in 24/7 operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production lines | Industry Standard: Semi-automated (ISO 9283 Level 2) Our Base: Fully automated (ISO 9283 compliance) Our Advanced: Sensor-driven automation (ISO 9283 Level 4) | ▲▲ Full cycle automation reduces labor costs by 40% Advanced: Real-time error detection (▲▲▲ 98% uptime) | Industry Standard requires manual intervention for packaging alignment |

| Material Handling Capacity | Bulk packaging of cleaning supplies | Industry Standard: 50 units/hour (ISO 3017) Our Base: 100 units/hour (ISO 3017) Our Advanced: 200 units/hour (ISO 3017) | ▲▲ Doubles throughput vs. Industry Standard Advanced: Handles mixed sponge sizes (▲▲ 30% faster changeovers) | Advanced requires dedicated operator training (▲▲▲ 40-hour certification) |

| Packaging Type Compatibility | Custom packaging for hygiene products | Industry Standard: Basic bags only Our Base: Bags + film (ASTM D3018) Our Advanced: Bags/film/pouch/foil (ASTM D3018 + ISO 14971) | ▲ Expands packaging options for premium branding Advanced: Foil sealing for moisture resistance (▲▲▲ 99.9% barrier) | Advanced adds 20% to upfront costs (▲▲▲$5K premium) |

| Power Efficiency | Energy-constrained manufacturing floors | Industry Standard: 1.5kW (IEC 60038) Our Base: 1.0kW (EU Energy Class A) Our Advanced: 0.8kW (EU Energy Class A+++) | ▲▲ 33% lower energy use vs. Industry Standard Advanced: Solar-ready design (▲▲▲ 20% cost savings/year) | Advanced requires specialized installation (▲▲▲ 2-day setup) |

| Hygiene Features | Medical/sanitary product packaging | Industry Standard: Basic sealing Our Base: UV sterilization zones (ISO 15883) Our Advanced: Sterilization + tamper-proof seals (ISO 15883 + ASTM F2263) | ▲▲▲ Eliminates cross-contamination (▲▲▲ 0% defect rate) Advanced: Traceable QR codes for compliance (▲▲▲ FDA audit-ready) | Base lacks tamper-proof features (▲▲▲ Requires manual inspections) |

| Warranty & Support | Long-term industrial use | Industry Standard: 6 months Our Base: 1 year (incl. 2 on-site visits) Our Advanced: 2 years + 24/7 remote support (ISO 13335) | ▲▲▲ 50% longer coverage than Industry Standard Advanced: Predictive maintenance alerts (▲▲▲ 30% fewer breakdowns) | Advanced support requires cloud subscription (▲▲▲ $200/month) |

⭐⭐⭐⭐⭐ James Peterson - Production Manager, GreenClean Inc.

"We've been using the CHLB Pro Model for 7 months now, and it has transformed our sponge packaging line. The fully automated system reduced our labor costs by nearly 50%, and the 80 units/hour output keeps us ahead of demand. Stainless steel build holds up perfectly under 24/7 operation."Purchase Date: February 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Khalid - Founder, EcoSponge Co.

"As a small home-based business, I needed something compact but reliable. The Base Model fits perfectly in my workshop and runs on standard 220V. It’s so intuitive—even with no prior experience, I had it running in under an hour. Packaging is consistent, and the sealed bags keep sponges hygienic for retail."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Carlos Mendez - Packaging Supervisor, HomeCare Producers Ltd.

"We upgraded to the Advanced Model for its foil compatibility and extended warranty. The machine handles mixed sponge sizes smoothly, and the 0.8kW energy efficiency is a big win for our green manufacturing goals. Only downside: initial setup took two full days, and the digital panel has a slight learning curve."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Lena Park - Operations Director, AsiaHygiene Supply

"We package sponges for both domestic and export markets. The CHLB machine allows us to customize bag sizes and switch between plastic and foil seamlessly. FDA-compliant materials give us confidence in passing international audits. With the Pro Model’s 3-year warranty, we’re confident in long-term ROI."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Daniel Foster - QC Lead, CleanTech Manufacturing

"Hygiene is non-negotiable for us. The UV sterilization zone and sealed chamber ensure zero cross-contamination. We’ve had 0 defect reports since deployment. Maintenance is simple—just rinse the nozzle and wipe down the stainless steel frame. A solid investment for any serious producer."Purchase Date: September 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Industrial Automation Consultant

"The CHLB series stands out in the mid-range packaging market. Its ISO 9283 Level 4 automation and real-time error detection place it ahead of most competitors in its class. For small to mid-sized manufacturers scaling up, the Advanced Model offers the best balance of performance, compliance, and support."

Marcus Lin - Green Manufacturing Specialist

"I recommend the CHLB machine for its energy efficiency (1kW base consumption) and compatibility with ultra-thin films, which reduces plastic waste by up to 20%. Combined with solar-ready Advanced and Pro models, this is a forward-thinking choice for eco-conscious producers."

Posted: 5 days ago

"Switched from manual packing to the CHLB Base Model. Setup was smooth, and the team adapted quickly. The digital control panel is intuitive, and we’re already seeing faster turnaround. Great value for startups."

Posted: 10 days ago

"Running two Pro Models side-by-side. They’ve held up flawlessly through high humidity and constant use. Stainless steel frame shows zero wear. Customer support responded within hours when we had a calibration query."

Posted: 3 weeks ago

"Love the speed and hygiene features. Only improvement? A clearer menu layout on the control screen. Otherwise, it’s been a seamless addition to our workflow."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.