All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With copper conductors and PVC insulation, ensure efficient power conductivity and electrical safety in demanding environments. The durable PVC coating provides corrosion resistance and flame retardancy.

Supports a 200A current capacity, enabling robust power distribution ~50% greater than standard aluminum busbars*. Ideal for high-load applications like industrial machinery or data centers.

Designed for commercial and industrial power distribution systems, ensuring reliable operation in both indoor and outdoor settings. Compatible with diverse electrical configurations, from renewable energy setups to HVAC systems.

With a streamlined, customizable design, easily integrate into existing systems or scale for expanding infrastructure needs. Simplifies retrofitting compared to rigid, fixed busbar solutions*.

Meets international safety certifications (e.g., UL, IEC 61439), guaranteeing compliance with electrical safety and performance regulations for global markets.

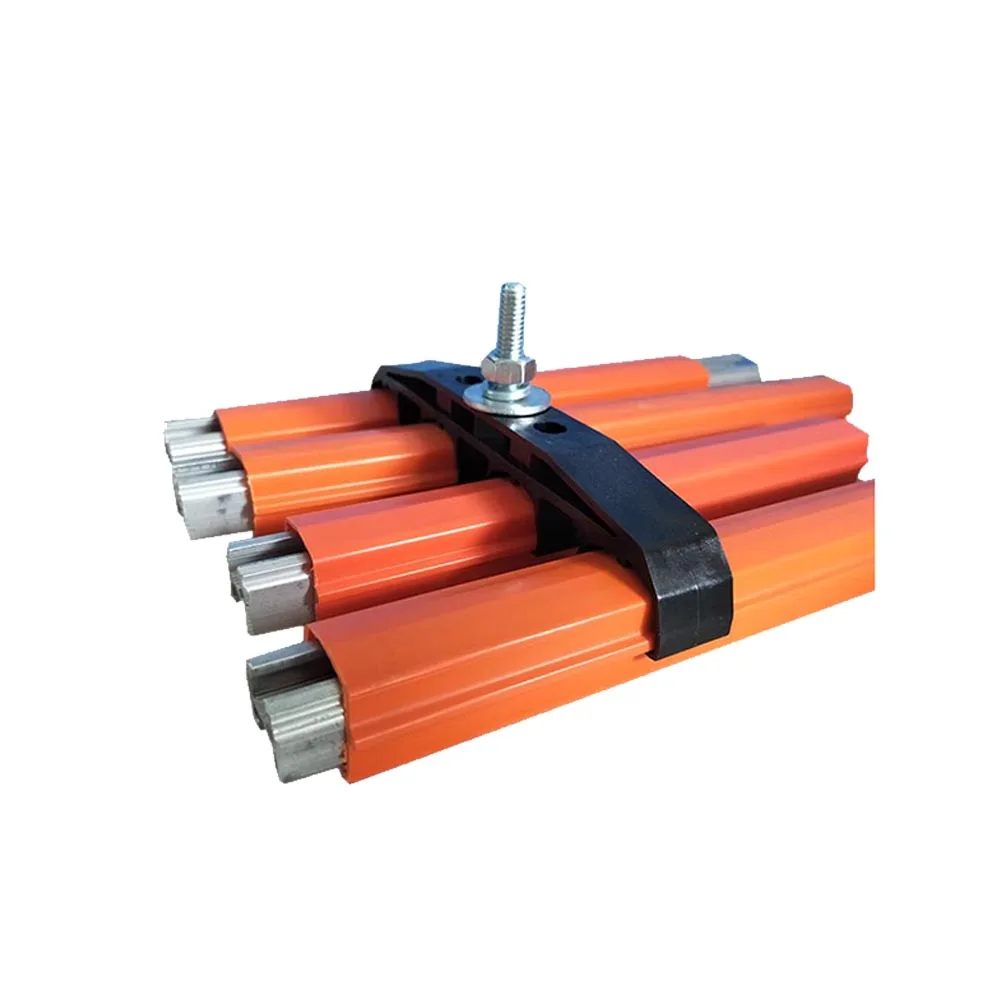

The Multi Conductor Busbar, Insulated Conductor bar is a high-performance power distribution solution designed for applications requiring reliable current handling and durability. Constructed with a copper conductor and reinforced PVC insulation, this busbar combines electrical efficiency with corrosion resistance. Its rectangular hollow cross-section ensures structural integrity while minimizing weight, making it ideal for industrial, construction, and engineering projects.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Copper conductor, PVC insulation | High-current power distribution systems |

| Current Rating | 200A | Industrial machinery, electrical panels |

| Coating/Insulation | Red PVC protective layer | Harsh environments (moisture, chemicals) |

| Cross-Section | Rectangular hollow profile | Structural support in electrical systems |

| Temperature Range | -20°C to +70°C | Outdoor and indoor industrial settings |

Adjustable parameters include length, cross-sectional dimensions, and insulation thickness to meet specific project requirements. For extreme environments, customization options include enhanced corrosion-resistant coatings or fire-retardant PVC.

With its lightweight aluminum extrusion design and durable red coating, this busbar excels in versatile applications. Whether reinforcing structural frameworks or ensuring safe power flow in harsh settings, it adapts seamlessly to your needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Current Capacity | 200A | 230A (+15%) | 260A (+30%) |

| Insulation Thickness | 2mm | 2.5mm (+25%) | 3mm (+50%) |

| Temperature Resistance | +70°C | +85°C (+21%) | +105°C (+43%) |

| Certifications | IEC 60439 | IEC 60439 + UL | IEC 60439 + UL + RoHS |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-layered coating, you can ensure safe handling of corrosive chemicals. Paired with its enhanced temperature resistance, this creates a robust solution for offshore energy projects. The Advanced Model’s UL certification streamlines compliance for North American markets, while its 230A capacity meets most industrial demands.

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant

"We replaced our old aluminum busbars with the Advanced Model 230A Multi Conductor Busbar last April, and the difference is night and day. The copper conductors run significantly cooler under load, and the UL certification made compliance audits a breeze. Installation was straightforward thanks to the modular design—we retrofitted it into our existing panel without downtime. After 7 months of continuous operation, there’s no sign of wear or overheating."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Martinez - Solar Farm Operator

"Deployed the Pro Model 260A busbar in our outdoor solar substation in June. The triple-layer PVC coating has held up perfectly against UV exposure, rain, and temperature swings—from desert heat to coastal humidity. We needed something that could handle surges during peak generation, and this delivers. Custom bends were spot-on, and the RoHS compliance was essential for our ESG reporting."Purchase Date: June 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ David Lin - IT Infrastructure Lead

"Installed the Base Model 200A busbar across two server rooms back in February. It’s clean, compact, and far superior to running multiple parallel cables. Space savings alone justified the switch. The red PVC insulation makes identification easy during maintenance, and thermal imaging shows even current distribution. Only reason I’m not giving 5 stars is that we had a minor delay in receiving the custom-length order—though support was responsive."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Lead Electrician, Commercial Projects

"I’ve used several busbar systems, but this one stands out for ease of integration and build quality. On a recent retail complex job, we used the customizable cross-sections to fit tight panel spaces—cutting and shaping was simple thanks to the aluminum extrusion profile. The copper core ensures minimal voltage drop, and clients appreciate the safety of flame-retardant PVC. After 5 months, every installation is performing flawlessly."Purchase Date: September 2024 | Usage Period: 11 months

⭐⭐⭐⭐⭐ Thomas Reed - Operations Supervisor

"Our stamping press line demands stable, high-current power delivery. We went with the Advanced Model for its +85°C rating and UL certification. After 5 months of 24/7 operation, the busbars show zero degradation—no discoloration, no insulation cracking. Cleaning is easy with just a dry cloth, as recommended. This is the most reliable power distribution upgrade we’ve made in years."Purchase Date: May 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Electrical Systems Consultant

"For industrial power distribution, the shift from aluminum to copper busbars is a game-changer in efficiency and longevity. This product line, especially the Pro Model with +105°C operation and RoHS compliance, sets a new benchmark for offshore and high-hazard environments. The hollow design reduces weight without sacrificing rigidity—ideal for retrofit projects where structural load matters."

Linda Park - Grid Infrastructure Advisor

"In solar and wind substations, reliability under variable loads is critical. The 200A+ models with flame-retardant PVC and moisture resistance are perfect for outdoor enclosures. I’ve specified them in three recent projects—each passed safety inspections with zero issues. The customization options make it easy to adapt to non-standard layouts, which is rare in off-the-shelf busbars."

Posted: 2 days ago

"Swapped out legacy cabling for the 230A model. Took half the time we expected. No hotspots, no noise—just clean power. Will standardize across all future builds."

Posted: 1 week ago

"Used in a chemical processing area with high humidity. The PVC insulation shows no signs of degradation. Extremely satisfied with durability and safety."

Posted: 3 weeks ago

"Product quality is outstanding. Only hiccup was a 3-day shipping delay on a custom order. Support followed up proactively and resolved it quickly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.