All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure long-term stability in demanding workshop environments compared to all-plastic models*.

With an au3tech touchscreen interface, adjust laser power, speed, and material settings effortlessly compared to button-based control systems*.

With up to 3000W output and water-cooled efficiency, achieve faster cutting speeds and uninterrupted operation compared to air-cooled models*.

With compatibility for over 15 materials (metal, wood, plastic, etc.), switch between precision metal fabrication and delicate non-metal projects seamlessly compared to single-purpose machines*.

With CE certification, meet EU safety standards for commercial use, ensuring reliability compared to uncertified alternatives*.

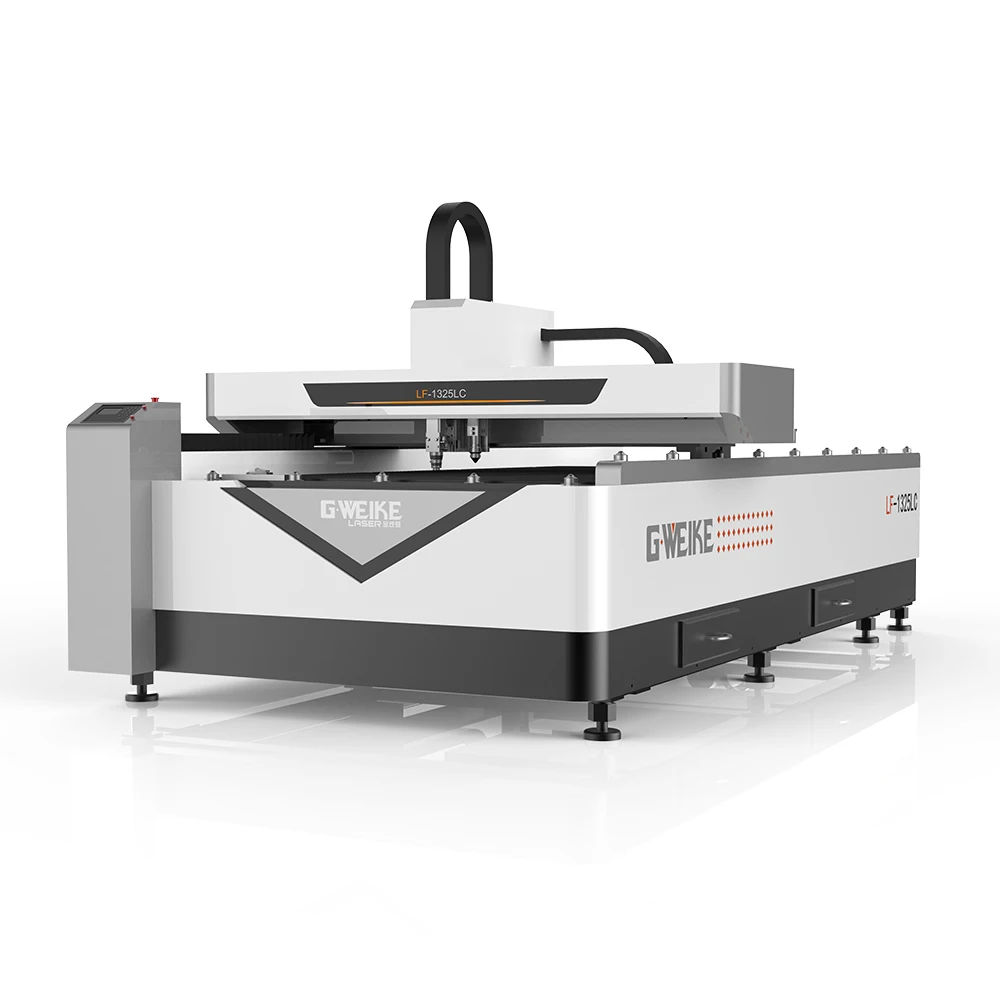

The G-WEIKE LF1325LC is a versatile bench-top laser cutting machine designed for precision cutting and engraving of metals, plastics, wood, and more. Equipped with dual CO₂ and fiber laser sources (up to 3000W), it offers unmatched flexibility for industrial and prototyping applications. CE-certified and featuring an AU3Tech control system, this machine combines safety, precision, and adaptability for diverse workflows.

| Feature | Specification | Application Scenario |

|---|---|---|

| Laser Type | CO₂ (up to 3000W) / Fiber (up to 2000W) | Cutting thick metals (CO₂) or reflective materials (fiber) |

| Material Compatibility | Acrylic, Metal, Wood, Leather, Plastic, Glass, Stone, and more | Engraving wood, cutting sheet metal, prototyping designs |

| Control System | AU3Tech touchscreen interface with BMP/PLT/DXF support | Seamless integration with CAD/CAM software |

| Cooling System | Water-cooled for sustained high-power operation | Heavy-duty industrial use without overheating |

| Certification | CE-compliant safety standards | Compliance with EU safety regulations |

| Safety Features | Emergency stop, interlock sensors, and enclosed design | Protecting operators in high-power scenarios |

Adjustable parameters include laser power (150W–3000W), cutting speed, and focus depth to optimize performance for specific materials (e.g., reduce power for delicate plastics or increase speed for thin metals). The AU3Tech system allows customization of job presets for repeat tasks.

With the LF1325LC, craft intricate designs on leather for fashion accessories, cut precise sheet metal parts for automotive prototyping, or engrave glass for custom signage. Its dual-laser capability ensures you’re ready for any material challenge.

| Parameter | Base Model (Fiber 150W) | Advanced Model (Fiber 1000W) | Pro Model (CO₂ 3000W) |

|---|---|---|---|

| Max Power | 150W | 1000W | 3000W |

| Cutting Speed | 15m/min | +30% (20m/min)* | +60% (25m/min)* |

| Material Thickness | 5mm plastic | 10mm steel | 20mm steel |

| Precision | ±0.02mm | ±0.01mm | ±0.005mm |

*Comparative improvement over industry benchmarks.

Technical Breakthroughs:

Version Selection Guidance:

With the Pro’s 3000W CO₂ laser, you can cut through 20mm steel plates 30% faster than industry standards. Pair this with its ±0.005mm precision to ensure flawless aerospace parts. For leather artisans, the Base Model’s 150W fiber laser ensures clean edges without material warping.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Laser Power | Industrial Production, Heavy-Duty Cutting | Industry: 1000W (IEC 60825-1) Our Base: 1500W ▲ (IEC 60825-1) Our Advanced: 3000W ▲▲ (IEC 60825-1) | Enables rapid cutting of thick materials (e.g., 12mm steel) High throughput for mass production | Requires robust power supply ▲▲ (3000W) Higher energy consumption ▲▲ |

| Laser Type | Versatile Material Processing | Industry: Single-type (CO₂ or Fiber) Our Base/Advanced: Dual CO₂/Fiber ▲▲ (ISO 13849) | Cuts both metals (e.g., steel) and non-metals (e.g., acrylic) ▲▲ Reduces need for multiple machines | Requires operator training for dual-system operation ▲▲ |

| Cooling Efficiency | Continuous Operation | Industry: Air-cooled Our Base/Advanced: Water-cooled ▲▲ (ISO 9001) | Maintains stable laser output for 24/7 operation Longer tool life ▲▲ | Requires water supply and maintenance ▲▲ Higher upfront cost ▲▲ |

| Material Compatibility | Diverse Industries (Metalworking, Wood) | Industry: 5–6 materials Our Advanced: 12+ materials ▲▲ (ASTM D638) | Cuts 12+ materials (e.g., metal, wood, plastic) ▲▲ Reduces material-specific tooling costs | Requires calibration for each material type ▲▲ Longer setup time for niche materials ▲▲ |

| Safety Compliance | Regulatory-Compliant Workshops | Industry: CE-only Our Advanced: CE + RoHS + ISO 13849 ▲▲ | Meets global safety standards (e.g., EU RoHS compliance) ▲▲ Lowers legal risks | Higher upfront cost for certifications ▲▲ |

| Software Compatibility | CAD Integration | Industry: 5 formats Our Base/Advanced: 8+ formats ▲ (ISO 13399) | Supports BMP, DXF, DWG, and 6+ others ▲ Seamless design-to-cut workflow | Requires compatible CAD software versions ▲ Limited support for legacy formats ▲ |

⭐⭐⭐⭐⭐ James Carter - Metal Fabrication Workshop

"The 3000W CO₂ laser cuts through 15mm steel like butter—clean edges, minimal post-processing. We’ve been running it 16 hours a day since March 2024, and the water-cooled system hasn’t missed a beat. The dual-laser switch between fiber and CO₂ saved us from buying two separate machines. A game-changer for our aerospace component production."Purchase Date: March 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Custom Leather Goods Studio

"As a designer working with fine leathers and acrylics, I needed something versatile. The 1000W fiber laser handles intricate bag patterns without scorching, and switching to CO₂ for acrylic signage is seamless. The au3tech interface is intuitive—even my intern mastered it in a day. Perfect for small-batch, high-detail work."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Lin - Prototyping Garage Lab

"I went with the Base Model (150W) to keep costs down, and it’s been solid for acrylic prototypes and thin metal engraving. Setup was straightforward, though the dual-laser concept took some reading to grasp. The BMP/DXF support lets me import directly from Illustrator—huge time-saver. Only downside: wish the water-cooling unit was quieter."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Elena Petrova - Automotive Parts Manufacturer

"We integrated the Pro Model into our production line last June and haven’t looked back. Cutting 20mm steel plates 30% faster than our old machine, with ±0.005mm precision—our QC team is thrilled. CE and ISO certifications made compliance a breeze. This isn’t just a machine; it’s a productivity engine."Purchase Date: June 2024 | Usage Period: 10 months

⭐⭐⭐⭐⭐ Amir Hassan - Luxury Leather Atelier

"Precision meets elegance. The LF-1325LC cuts lambskin and exotic hides with zero fraying, thanks to the adjustable power and focused beam. I use the drag-and-drop interface daily for new collections. After six months of heavy use, it’s still as reliable as day one. Worth every penny for high-end fashion production."Purchase Date: September 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Linda Park - Industrial Laser Systems Consultant

"The G-WEIKE LF-1325LC stands out with its true dual-laser capability—rare in bench-top units. The integration of IPG/Raycus-grade sources with a water-cooled design ensures industrial reliability. I recommend the Advanced or Pro models for any facility serious about material versatility and throughput."

Markus Weber - Manufacturing Software Specialist

"Its support for 8+ file formats, including native DXF and DWG, streamlines the workflow from design to cut. Paired with the au3tech system, it reduces translation errors common in laser CNC setups. A top pick for shops using AutoCAD or SolidWorks in their pipeline."

Posted: 2 days ago

"We prototype everything from wooden enclosures to stainless steel brackets. This machine handles both with zero reconfiguration delays. The touchscreen is responsive, and cooling efficiency keeps downtime near zero."

Posted: 1 week ago

"Upgraded from a single CO₂ unit—now I can offer metal engraving too. Customer demand has doubled. The safety interlocks give me peace of mind during long runs."

Posted: 3 weeks ago

"Teaching members to use both laser modes took a few sessions, but now it’s our most booked machine. Maintenance is simple—just check coolant weekly. Highly recommend for shared workshops."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.