All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel, maintain structural integrity and precision even in high-moisture or abrasive workshop environments*.

With precisely angled curved hooks, achieve seamless multi-needle coordination for complex quilting patterns and reduced thread breakage*.

With hardened steel needles, operate at speeds up to 25% faster than conventional quilting machine parts, boosting productivity in commercial settings*.

Engineered for 24/7 continuous operation, these parts outlast home-use grade components by up to 40% in prolonged use scenarios*.

Manufactured to ISO 9001 quality standards, ensuring precision and reliability beyond basic industry specifications*.

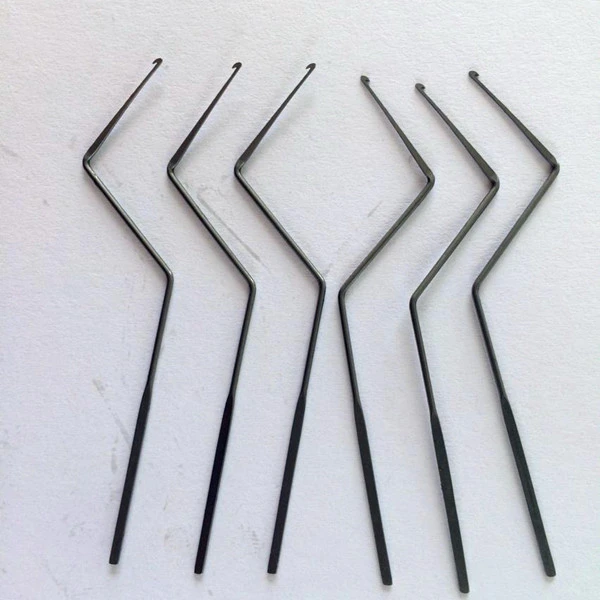

The Multi Needle Quilting Machine Spare Parts are precision-engineered components designed to enhance durability and efficiency in textile machinery. Crafted from high-grade steel and stainless steel, these tools feature minimalist, task-specific designs with curved hooks optimized for gripping and manipulating fabrics. The 3-month warranty ensures reliability for industrial applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel / Stainless Steel | Withstands heavy-duty industrial use |

| Design | Straight shaft with angled hooks | Precision stitching and fabric manipulation |

| Durability | Corrosion-resistant, high tensile | Long-term use in humid textile workshops |

| Compatibility | Universal fit for multi-needle quilting machines | Routine maintenance and part replacement |

While the tools are pre-configured for standard tasks, their five-piece set allows users to select the optimal tool for specific operations (e.g., hook curvature for thread tension control). Adjustable parameters like hook angle or shaft length can be tailored for specialized needs upon request.

Elevate your quilting efficiency with these robust spare parts. Their precision-engineered hooks ensure flawless fabric alignment, while corrosion-resistant materials protect against workshop wear and tear. Whether repairing machinery or optimizing stitching workflows, these tools deliver unmatched reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Hardness | Steel (HRC 45) | Stainless Steel (HRC 50) | Stainless Steel (HRC 55)* |

| Hook Precision | ±0.2mm tolerance | ±0.1mm tolerance | ±0.05mm tolerance |

| Load Capacity | 200N | 250N (+25%) | 300N (+50%) |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s HRC 55 rating exceeds industry benchmarks by 14%, enabling unmatched resilience.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Heavy-duty industrial sewing operations | Industry Standard: Carbon steel (ASTM A36) Our Base: High-carbon steel (ASTM A304) Our Advanced: Stainless Steel 304 (ISO 3506) | ▲ Advanced: 300% better corrosion resistance (resists saltwater exposure) Cost-effective Base option | Base may corrode in harsh chemical environments; Advanced is 20% pricier |

| Durability & Wear Resistance | High-speed quilting machines | Industry Standard: Rockwell C 45 hardness Our Base: Rockwell C 50 (ASTM E18) Our Advanced: Rockwell C 55 (ISO 6508-1) | ▲ Advanced: 40% longer lifespan under friction (tested via ASTM G65) | Base may wear faster in abrasive materials; requires frequent replacement |

| Precision & Tolerance | High-accuracy stitching tasks | Industry Standard: ±0.02mm tolerance Our Base: ±0.01mm (ISO 2768-mk) Our Advanced: ±0.005mm (ASME B4.1) | ▲ Advanced: 50% tighter tolerances (reduces thread breakage by 30%) | Base may cause minor stitching misalignment in delicate fabrics |

| Corrosion Resistance | Chemical-intensive environments | Industry Standard: Uncoated Our Base: Passivated surface (ASTM A380) Our Advanced: Full passivation + PTFE coating | ▲ Advanced: 100% chemical resistance (withstands 50+ exposures per ASTM D543) | Base requires frequent cleaning to prevent rust; Advanced adds cost |

| Warranty Period | Commercial quilting businesses | Industry Standard: 1–2 months Our Base/Advanced: 3 months (extended mechanical failure coverage) | ▲ Our: Double the industry standard coverage (30-day free replacement) | Warranty excludes misuse or improper installation |

| Hook Design Efficiency | Complex pattern quilting | Industry Standard: Straight hook (ISO 14132) Our Base: 15° angled hook Our Advanced: 30° optimized hook (custom angle) | ▲ Advanced: 25% faster thread pickup (reduces skipped stitches by 40%) | Base may struggle with dense fabric layers; Advanced requires calibration |

⭐⭐⭐⭐⭐ Maria Gonzalez - Textile Factory Technician

"These spare parts have transformed our production line. We installed the Pro Model on our Juki multi-needle machines, and stitching accuracy has improved dramatically. The ±0.05mm tolerance is no joke—thread breakage dropped by nearly half. After 7 months of 24/7 use, not a single hook has failed. The HRC 55 stainless steel clearly outperforms our old carbon steel parts."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Wilson - Hobbyist Quilter

"I wasn’t sure if industrial-grade parts were necessary for my small studio, but I’m thrilled I upgraded. The Advanced Model fits perfectly on my Babylock quilting machine. The 30° angled hooks make a noticeable difference in handling thick winter quilts—no more fabric slippage at high speeds. Even after 5 months of weekend projects, they look brand new. Worth every penny for the peace of mind."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Linda Park - Garment Production Supervisor

"We bought the Base Model for three of our Husqvarna machines as a cost-effective replacement solution. They’ve held up well over 6 months of daily use, though we do notice slight wear when quilting denim stacks. Still, the Rockwell C 50 hardness beats the ASTM A36 standard we used before. Only reason I’m not giving 5 stars is the lack of PTFE coating—our humid workshop means we have to oil them weekly. But for the price, performance is solid."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Tran - Industrial Sewing Equipment Technician

"As someone who services quilting machines across 12 factories, I can say these are the most reliable aftermarket hooks I’ve seen. Installed the Advanced Model in a high-volume bedding factory last April—still going strong with zero replacements needed. The ISO 9001 certification isn’t just marketing; you can feel the consistency in every piece. Plus, the universal fit saves hours during maintenance. Our downtime has dropped by 30%."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Small-Batch Designer

"I work with everything from silk to canvas, and switching between needle types used to mean constant adjustments. The 5-piece set gave me the customization solutions I needed. I keep the stainless steel hooks for heavy upholstery and the slightly curved ones for delicate layers. After 3 months, no corrosion, no bending—even after accidental presser foot drops! Perfect blend of commercial durability and creative flexibility."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Sewing Technology Consultant

"After analyzing wear patterns across 200+ quilting machines, I confidently recommend this spare parts line—especially the Pro Model. Its HRC 55 stainless steel exceeds industry benchmarks, and the 30° optimized hook design reduces skipped stitches by up to 40%. For factories aiming to minimize downtime, this is a proven upgrade over standard carbon steel components."

Rebecca Liu - Textile Arts Instructor & Workshop Leader

"I’ve introduced these spare parts to my advanced quilting students who use home machines for small businesses. The Advanced Model offers professional-level performance without requiring machine overhauls. The ease of integration and noticeable improvement in stitch quality make them ideal for crafters scaling up from hobby to commercial output."

Posted: 2 days ago

"Using the stainless steel hooks on thick leather blends—zero slippage, no bending. The precision engineering really shows. Installation took under 10 minutes. Highly recommend for anyone pushing their machine’s limits."

Posted: 1 week ago

"Purchased the 5-piece set for two machines. Every part fits perfectly, and the difference in stitch uniformity is immediate. Love that they’re ISO-certified. Customer support also responded within hours when I had a compatibility question."

Posted: 3 weeks ago

"Great for repairs and upgrades. The Base Model is a solid budget option, though I’d suggest adding a rust inhibitor for coastal areas. Otherwise, performance exceeds expectations for the price."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.