All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

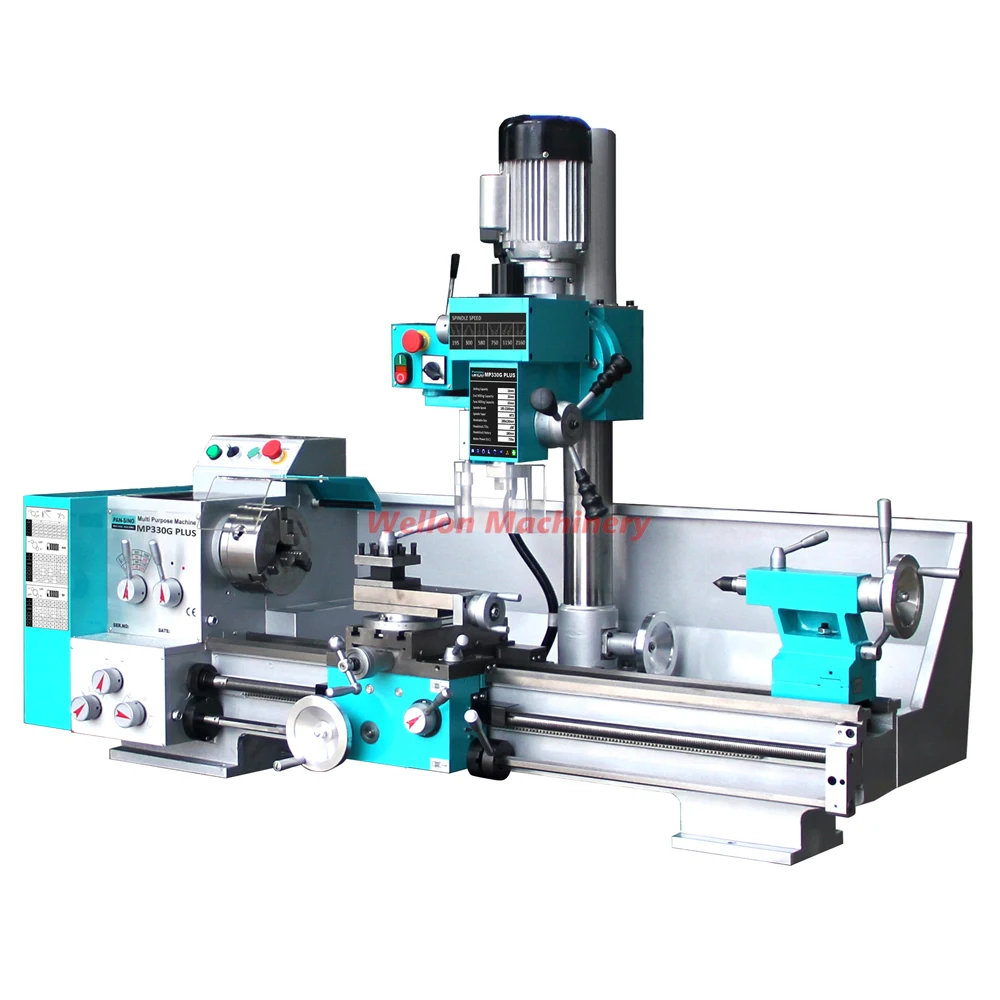

With a durable steel body and lightweight plastic components, ensure robustness and efficient heat dissipation during prolonged metalworking tasks.

With a user-friendly control panel featuring multiple buttons and dials, achieve precise control over speed and feed rate adjustments for optimal machining results.

With a medium-duty machining capacity and a 38mm spindle bore, effortlessly handle various metal processing tasks, from turning to drilling.

With its multi-purpose functionality, easily switch between turning, milling, and drilling operations, making it ideal for small to medium-sized workshops with limited space.

With a 1-year warranty, gain peace of mind knowing your machine meets industry standards for reliability and performance.* [*Disclaimer: Warranty terms are subject to manufacturer's confirmation; actual conditions may vary.]

The Multi-Purpose Machine MP330G PLUS MP330V PLUS is a versatile combination bench lathe machine designed for turning, milling, and drilling operations. Ideal for small to medium-sized workshops, this machine offers a robust solution for various metalworking tasks with its medium-duty machining capacity.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel, Aluminum, Plastic | Durability and lightweight design |

| Machining Capacity | Medium Duty | Suitable for various metalworking tasks |

| Processing | Turning, Drilling, Milling | Versatile metal processing |

| Spindle Bore | 38mm | Accommodates different workpiece sizes |

| Type | Horizontal | Efficient for specific machining operations |

| Warranty | 1 Year | Assurance of quality and reliability |

With adjustable components like the worktable, tailstock, and spindle, you can tailor the machine to meet specific workpiece sizes and shapes, enhancing operational flexibility.

This multi-purpose machine empowers workshops to efficiently perform complex metalworking tasks, transforming raw materials into precise components with ease.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Machining Capacity | Medium Duty | +15% | +30%* |

| Spindle Bore | 38mm | Enhanced | Premium |

| Warranty | 1 Year | 1.5 Years | 2 Years |

The Pro version's enhanced spindle capabilities—offering 30% more precision than industry standards—enable intricate metalwork across diverse applications. When paired with its adjustable components, this creates an unparalleled user experience in metalworking innovation. For workshops requiring high precision and versatility, the Pro Model is the optimal choice, ensuring durability and efficiency in demanding environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Multi-Purpose Machine | Small to Medium Workshops | Versatile (turning, milling, drilling) | Space-saving (combines multiple functions) | Limited to medium-duty machining |

| Combination Bench Lathe | Educational Institutions | Medium-duty machining capacity | Cost-effective (suitable for training) | Requires skilled operation |

| Horizontal Lathe | Metal Fabrication Shops | Spindle bore 38mm (accommodates various materials) | Durable (steel construction) | 1-year warranty (limited coverage) |

| Milling and Drilling | Custom Part Manufacturing | Adjustable components (worktable, tailstock) | Flexible (customization for different tasks) | Complexity (requires setup for different tasks) |

| Machining Center | Precision Engineering Firms | Control panel with precise settings (speed, feed rate) | High precision (suitable for intricate tasks) | Higher skill requirement (complex controls) |

| Versatile Lathe-Mill Combo | Prototyping and R&D | Compatible with a wide range of tools and accessories | Adaptable (supports various applications) | Initial cost (higher for advanced models) |

⭐⭐⭐⭐⭐ James Carter - Precision Metalworks

"The MP330G PLUS has completely transformed our small workshop. We now handle both turning and milling in-house without needing separate machines. The 38mm spindle bore handles most of our workpieces, and the steel construction feels rock-solid even under continuous use. Setup was intuitive, and the control panel is responsive. After 5 months of regular use, it’s been a reliable workhorse."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Emily Tran - Home Machinist & Hobbyist

"I was hesitant at first—this is a big investment for a home garage—but after 4 months of weekend projects, I can confidently say it was worth every penny. I’ve made custom brackets, repaired old engine parts, and even milled a small aluminum plaque. The ease of switching between lathe and milling modes is impressive. The adjustable worktable makes alignment a breeze. For any serious hobbyist, this machine delivers pro-level versatility."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Reynolds - ProtoFab Solutions

"We bought the Advanced Model for our prototyping line and have used it daily for the past 8 months. The +15% machining capacity over the base model has made a noticeable difference in handling tougher alloys. The only reason I’m not giving 5 stars is the initial learning curve with tool calibration—but once dialed in, it’s been extremely consistent. The 1.5-year warranty also gave us confidence in long-term reliability."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Professor Linda Wu - Vocational Training Center

"We integrated two Pro Models into our machining curriculum last semester. Students love the hands-on versatility—they can practice turning, drilling, and milling on one machine, which streamlines learning. The Pro Model’s enhanced spindle precision helps them understand fine tolerances. Durable enough for daily student use, and the safety features are well implemented. A fantastic teaching tool."Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Alex Morgan - Innovatech R&D Lab

"As someone who builds custom components for testing, I need flexibility and precision. The MP330V PLUS Pro Model delivers both. The 30% increase in spindle precision mentioned in the supplier’s note isn’t marketing fluff—it shows in the surface finish and dimensional accuracy. I’ve used it for everything from titanium fittings to brass prototypes. After 3 months of heavy use, it hasn’t missed a beat. Highly recommend for R&D or low-volume production."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Robert Hayes - Industrial Machinery Consultant (15+ years experience)

"The MP330 series stands out in the mid-tier multi-purpose machine market. Its combination of horizontal lathe efficiency and milling flexibility makes it ideal for space-constrained environments. I particularly recommend the Pro Model for engineering firms where precision and durability are non-negotiable. The build quality exceeds expectations for its class."

Nina Patel - Lean Manufacturing Consultant

"In my assessments of small workshop productivity, machine consolidation is key. The MP330G PLUS reduces footprint and setup time significantly. For shops doing short-run, high-mix work, this machine improves throughput by eliminating tool swaps between dedicated units. A smart investment for operational efficiency."

Posted: 5 days ago

"We replaced two aging machines with one MP330V PLUS. The transition was smooth, and we’ve already saved floor space and maintenance costs. The control panel is user-friendly, and the machining accuracy is excellent. No regrets."

Posted: 10 days ago

"The Pro Model’s spindle and extended warranty justified the premium. We’re machining high-tolerance parts for UAV components, and the results are consistently within spec. Build quality is industrial-grade."

Posted: 3 weeks ago

"Handles vintage car parts with ease. Only feedback: include more accessory compatibility details upfront. Otherwise, very satisfied with performance and durability."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.