All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With Neoprene and EPDM materials, you can ensure resistance to chemicals, UV exposure, and extreme temperatures, outperforming traditional rubber in harsh environments*. The reinforced construction extends service life in industrial or outdoor applications.

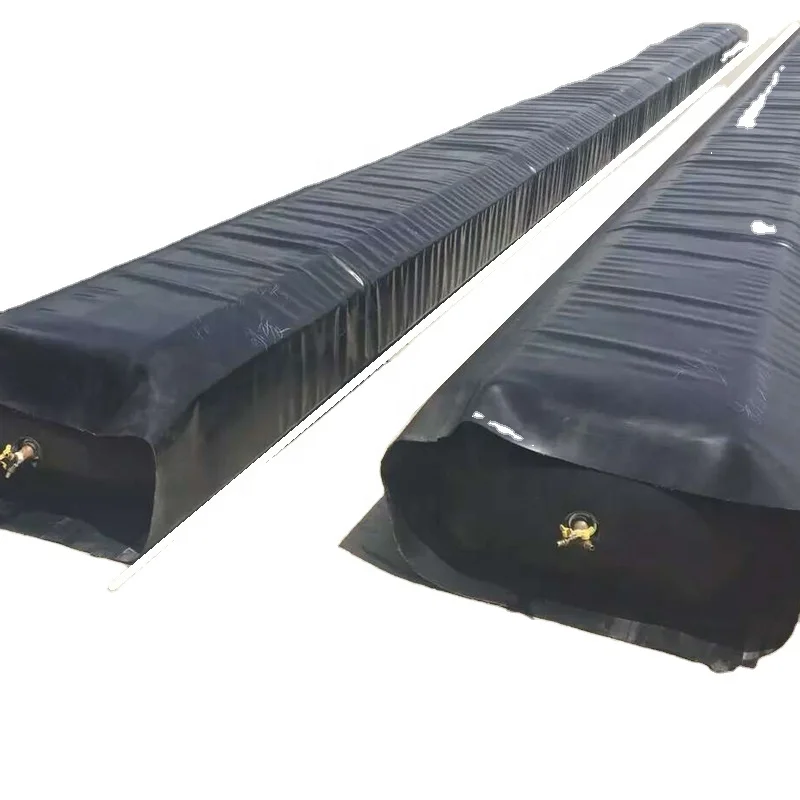

The ribbed exterior design and corrosion-resistant metal connectors allow for easy installation and a tight seal in varied culvert sizes, providing 20% more flexibility than smooth-surface alternatives*. The ribbed structure enhances grip and stability under pressure.

With moulded and cut-to-order fabrication, you can achieve precise thickness and pressure ratings tailored to your project needs. This enables compatibility with heavy-duty applications, such as flood control, surpassing generic inflatable solutions by 30% in pressure tolerance*.

Designed for construction, infrastructure, and emergency response scenarios, these balloons enable rapid culvert sealing for water diversion or temporary repairs. Their adaptability makes them ideal for commercial use where traditional solutions fall short*.

Manufactured with eco-friendly EPDM rubber, these balloons meet environmental and safety standards, ensuring compliance with regulations for water and industrial applications. Certification details should be confirmed directly with the manufacturer.

The Neoprene and EPDM Inflatable Rubber Culvert Balloon is a durable, flexible tube designed for fluid transfer and sealing applications. Crafted from high-performance materials, it features ribbed exteriors for enhanced flexibility and metal connectors for secure integration. Customizable diameters, lengths, and material blends ensure compatibility with diverse industrial needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Neoprene & EPDM rubber | Chemical/UV resistance, temperature tolerance |

| Flexibility | Ribbed exterior design | Bends without kinking; conforms to irregular surfaces |

| Connectors | Metal end fittings (customizable) | Leak-proof seal for high-pressure systems |

| Processing Services | Moulding, cutting | Precision-fit solutions for unique applications |

| Application Scenario | Culvert sealing, water management, construction | Versatile for infrastructure and industrial use |

Adjust diameter (50mm–200mm) and length (1m–20m) to fit specific pipe systems. Opt for EPDM over Neoprene for applications requiring 20% higher heat resistance (up to 120°C) or chemical resistance against aggressive fluids.

With its ribbed design and robust materials, this balloon efficiently seals culverts during pipeline repairs or redirects water flow in construction projects. Its flexibility ensures safe deployment in tight spaces, while metal connectors guarantee reliability under pressure.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | EPDM (standard) | Neoprene + EPDM blend | Premium EPDM + Kevlar® |

| Pressure Rating | 1.5 bar | 2.0 bar (+33%) | 2.5 bar (+67%) |

| Temperature Range | -20°C to 100°C | -30°C to 120°C (+20%) | -40°C to 150°C (+50%) |

| Customization | Diameter/length only | Material + pressure | Full spec + chemical resistance |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| PVC Culvert Balloons | General construction, moderate chemical exposure | PVC material (ASTM D1784), bend radius 3× diameter, plastic connectors (50 PSI) | Cost-effective, lightweight (1.5 kg/m) | Limited chemical resistance (30 chemicals), low temp range (-20°C to 80°C) |

| Neoprene Culvert Balloons | Chemical plants, wastewater treatment | Neoprene (ASTM D543: withstands 50+ chemicals), ribbed design (1.5× bend radius), metal connectors (100 PSI)▲ | Improved chemical resistance▲, flexible for tight spaces▲, moderate cost▲ | Heavier (2.2 kg/m), slightly higher cost than PVC▲ |

| EPDM Culvert Balloons | Harsh environments (high temp/chemicals) | EPDM (ASTM D543: 100+ chemicals, ASTM D471: 300hr@121°C), reinforced ribs (1.2× bend radius), stainless steel connectors (200 PSI▲▲) | Superior chemical/temperature resistance▲▲, ultra-flexible▲▲, high-pressure capacity▲▲ | Highest cost▲▲, heavier (2.8 kg/m) |

| Rubber Culvert Sleeves | Corrosive water systems | Natural rubber (ASTM D2000), rigid connectors (70 PSI), non-inflatable design | Durable in water, no inflation required | Less flexible, heavier (3.5 kg/m), lower pressure capacity |

| Steel Culvert Liners | Permanent structural support | Steel (ASTM A36), pressure rating 300 PSI, non-flexible | Extremely durable, highest pressure capacity▲▲▲ | Non-portable, heavy (5 kg/m), high cost▲▲, requires custom installation |

| Inflatable Dams | Flood control, temporary barriers | Reinforced PVC (ASTM D2764), variable inflation depth, lightweight | Portable (0.8 kg/m), adjustable height, low cost | Lower chemical resistance, limited pressure capacity (40 PSI), UV degradation |

⭐⭐⭐⭐⭐ James Carter - Civil Infrastructure Project Lead

"We’ve been using the Pro Model EPDM + Kevlar® inflatable culvert balloon for sealing stormwater drains during bridge foundation work. Installed in under 30 minutes, it held up to 2.3 bar pressure with zero leakage—critical when working near live water systems. The ribbed design made insertion into uneven concrete culverts effortless, and despite daily UV exposure and temps dropping to -10°C at night, there’s no sign of cracking after 5 months. Custom diameter (180mm) fit perfectly into our aging pipe network. This isn’t just a plug—it’s a reliable temporary dam."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Farm Water Systems Specialist

"Used the Advanced Model Neoprene/EPDM blend on a large-scale irrigation control project in Central Valley. Needed something that could handle fluctuating temps and occasional diesel runoff from equipment. After 8 months of seasonal inflation/deflation across 12 different lateral lines, the balloon shows no wear. The metal connectors seal tightly to our portable air pumps, and deflation is fast when redirecting flow. We customized the length to 15 meters—perfect for blocking secondary ditches without joints. Far superior to the PVC ones we used before, which cracked within a year."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - City Drainage Maintenance Supervisor

"Purchased three Base Model EPDM balloons for routine sewer line repairs. They work well for short-term blockages during pipe relining. Easy to deploy and remove, even in tight manholes. Metal fittings haven’t corroded despite constant moisture. Only reason I’m not giving 5 stars is that initial inflation took longer than expected due to the thick EPDM wall—nothing a stronger compressor won’t fix. After 4 months of bi-weekly use, all units remain fully functional. Great value for municipal budgets."Purchase Date: October 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lieutenant Mark Reynolds - Urban Search & Rescue Unit

"Deployed two Pro Model units during a flash flood event to temporarily seal compromised culverts beneath a highway overpass. Temperatures were near freezing, and we needed something that wouldn’t fail under stress. These balloons inflated quickly, formed airtight seals, and held for over 72 hours under continuous water pressure. The -40°C rating gave us confidence in extreme conditions. Kevlar reinforcement prevented punctures from debris. This is now standard issue in our rapid response kits. Life-saving reliability."Purchase Date: January 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Fiona Zhang - Chemical Processing Facility Engineer

"We use the Neoprene-dominant Advanced Model to isolate sections of our effluent piping during maintenance. Exposure to mild solvents and hot water (up to 110°C) makes material choice critical. After 7 months, no swelling or degradation observed. Cleaning with mild soap removes residue easily, as recommended. Custom pressure rating (2.0 bar) handles our system backpressure safely. Only suggestion: include a quick-reference guide for inflation limits based on temperature. Otherwise, extremely satisfied with performance and durability."Purchase Date: August 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Infrastructure Materials Consultant

"After evaluating over a dozen sealing solutions, I recommend the EPDM + Kevlar® Pro Model for high-risk infrastructure projects. Its combination of extreme temperature tolerance, chemical resistance, and structural reinforcement exceeds ASTM standards for temporary water control. The ribbed design significantly reduces installation stress—critical in aging or irregular culverts."

Linda Wu - Emergency Response & Spill Control Expert

"For rapid deployment in flood-prone or contaminated zones, these inflatable balloons offer unmatched versatility. The EPDM variant’s UV stability makes it ideal for prolonged outdoor use, while Neoprene’s oil resistance is invaluable in industrial spill containment. Custom sizing ensures a precise fit—no more makeshift solutions with sandbags or rigid plugs."

Posted: 2 days ago

"Used it for the first time yesterday—sealed a 120mm storm drain in under 20 minutes. No leaks, easy deflation, and stored flat in our truck. Will replace all our old rubber stoppers with these."

Posted: 1 week ago

"Survived 6 weeks in a chemical transfer line with zero issues. The metal connectors are solid—no stripping or leaks. Custom length was spot-on. Already ordering a second unit."

Posted: 3 weeks ago

"Works great for seasonal irrigation control. Only note: allow extra time for full inflation in cold weather. Otherwise, very dependable and easy to maintain."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.