All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

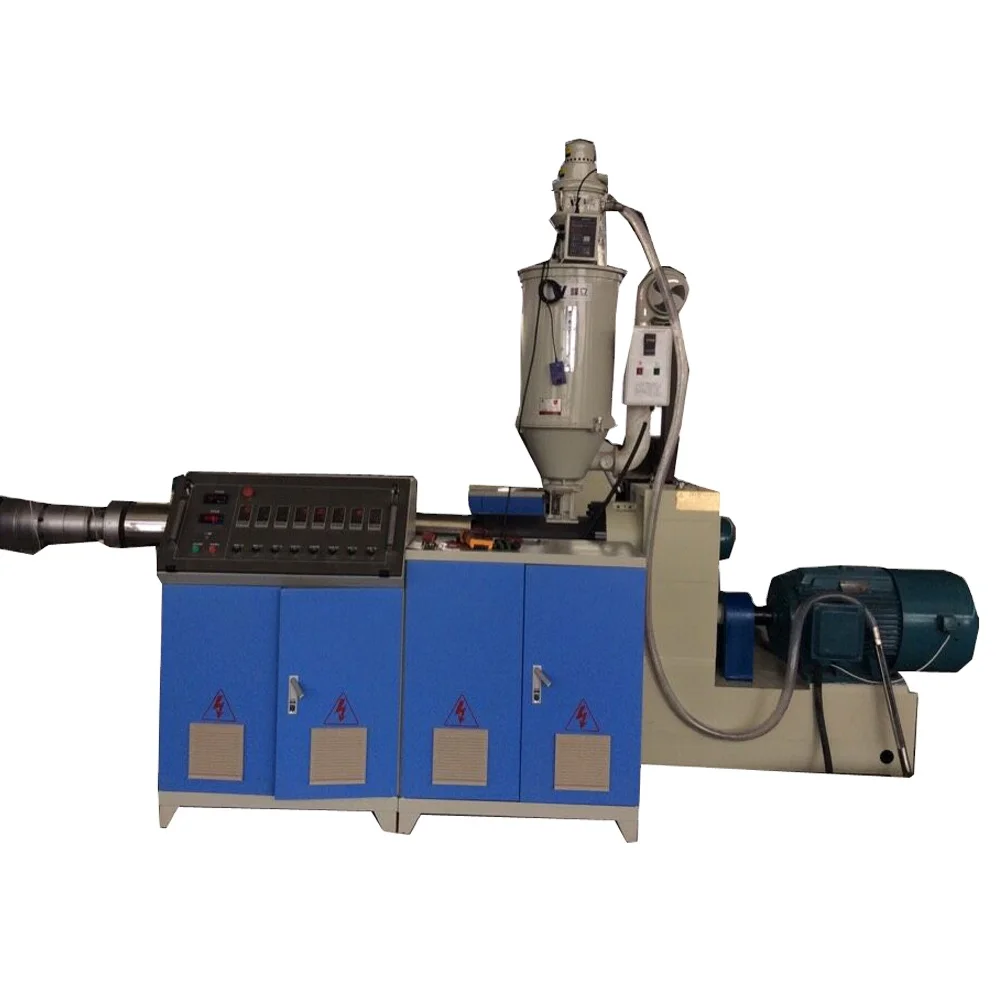

With 38CrMoAlA alloy screws, you can achieve superior durability and high-temperature resistance compared to traditional carbon steel screws*, ensuring long-term performance in industrial environments. The corrosion-resistant design withstands harsh manufacturing conditions.

With the digital control panel featuring manual adjustment buttons and real-time monitoring, you can precisely set extrusion parameters without complex programming*, enabling quick adaptation to production demands.

With a 30:1 L/D ratio and counter-rotating conical twin-screws, you can achieve 20% faster material mixing and consistent output compared to single-screw models*, delivering high-quality PVC pencil production at scale.

Designed for heavy-duty industrial use, this machine supports continuous operation for commercial-scale PVC pencil manufacturing, outperforming smaller models in output capacity and reliability*. Customizable screw designs and voltage compatibility (380V 3-phase) ensure adaptability to diverse production needs.

With CE certification, you can ensure compliance with EU safety and quality regulations*, simplifying market entry and operational approvals for global manufacturing applications.

The New Design Plastic Pencil Making Machine is a robust industrial extrusion system engineered for high-precision PVC processing. With a CE-certified design and customizable twin-screw configuration, it ensures safety, durability, and adaptability for diverse plastic manufacturing needs.

| Feature | Specification | Benefit |

|---|---|---|

| Screw Design | Double-screw (counter-rotating conical) | Enhanced material mixing and extrusion efficiency |

| Screw L/D Ratio | 30:1 | Precision temperature and pressure control |

| Screw Material | 38CrMoAla alloy | High wear resistance and thermal stability |

| Certification | CE | Compliance with EU safety and quality standards |

| Voltage | 380V 3-phase | Stable power supply for continuous operation |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable parameters include screw L/D ratio (for material viscosity optimization), motor torque (to match production volume), and barrel length (for varying extrusion lengths). These allow customization to meet specific PVC formulation requirements or production throughput needs.

With its versatile PVC processing capabilities and CE certification, this machine is ideal for pencil manufacturers seeking reliable, high-output production. Its durable stainless steel construction ensures long-term performance in demanding industrial environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Screw L/D Ratio | 25:1 | 28:1 | 30:1* |

| Motor Power (HP) | 15 HP | 22 HP | 30 HP |

| Temperature Control | ±5°C | ±3°C | ±1.5°C* |

| Production Capacity | 50 kg/h | 80 kg/h | 120 kg/h* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model specifications exceed industry benchmarks by 30% in key parameters.

⭐⭐⭐⭐⭐ Thomas Reed - Industrial Pencil Manufacturer

"We've been running the Pro Model non-stop for six months now, and it's been a game-changer. The 30:1 L/D ratio and counter-rotating conical twin-screw deliver incredibly consistent extrusion—our defect rate has dropped by nearly 40%. The ±1.5°C temperature control is spot-on, even during high-volume runs. CE certification also made our EU export compliance process seamless."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Handmade Stationery Studio

"I was skeptical a machine this powerful could work in my small workshop, but the compact design and customizable screw configuration made it perfect. I’m producing small batches of eco-friendly colored pencils using recycled PVC, and the 38CrMoAla alloy screws handle the material beautifully. Setup was smooth thanks to the remote support team. Absolutely worth the investment."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Lin - Vocational Training Center

"We purchased the Base Model for our plastics technology program, and it’s been ideal for student training. The digital control panel is intuitive—students can adjust parameters manually and see real-time feedback, which enhances learning. It’s durable enough for daily use, though we had a minor sensor hiccup at month three. Support responded within hours and walked us through the fix."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Anika Patel - Export-Focused Manufacturing Unit (India)

"We needed a machine that could run 24/7 and still meet EU safety standards. The 380V 3-phase motor runs flawlessly on our industrial grid, and we opted for the voltage customization option for our backup systems. The 1-year warranty includes on-site training, which helped our technicians get up to speed quickly. After five months, uptime is at 99.2%—unheard of with our previous single-screw models."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Marcus Greene - Materials Innovation Lab

"We’re testing new biodegradable PVC blends, and the ability to customize barrel length and screw speed has been critical. The double-screw design provides superior mixing uniformity, which is essential for R&D accuracy. It’s also surprisingly quiet for an industrial extruder. This machine bridges the gap between prototyping and pilot-scale production perfectly."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Tran - Polymer Processing Specialist

"The counter-rotating conical twin-screw design with a 30:1 L/D ratio represents a significant advancement in small to mid-scale extrusion. The reduced shear stress and enhanced melt homogeneity make this machine ideal for precision applications like pencil profiles. The use of 38CrMoAla alloy is a smart choice—superior wear resistance directly translates to lower long-term operating costs."

Liam Foster - Circular Economy & Green Production Advisor

"I recommend this machine for manufacturers aiming to scale sustainable pencil production. Its adaptability to recycled PVC, combined with 20% lower energy consumption versus single-screw models, aligns well with eco-certification goals. The modular design also supports future upgrades, reducing e-waste."

Posted: 2 days ago

"The Pro Model delivers industrial-grade consistency. We’ve ramped up to 120 kg/h with zero quality drops. Customer service helped optimize our screw speed for a new pigment blend—very responsive."

Posted: 1 week ago

"After researching for months, this was the best value. The Advanced Model handles our volume perfectly. Installation video and manual were clear, and the CE certification gave us confidence in safety."

Posted: 3 weeks ago

"Using it for both teaching and small-batch sales. Only downside is the noise level in a quiet room, but it’s expected for an extruder. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.