All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure hygienic and durable performance in high-demand food processing environments*. This material outperforms traditional models using less durable alloys, maintaining structural integrity even in humid or acidic conditions.

With intuitive control panels and streamlined design, you can operate the machine effortlessly, reducing training time compared to complex industrial equipment*. The straightforward interface allows quick adjustments for peeling, cleaning, or pureeing tasks.

With high-volume peeling capabilities, you can process up to 50% more onions per hour than manual methods*, maximizing efficiency in commercial kitchens or food plants. The 220V power ensures consistent performance for industrial-scale operations.

With robust construction optimized for continuous operation, you can meet the demands of 24/7 commercial environments, outperforming home-use models prone to overheating or fatigue*. Ideal for large-scale food processing workflows.

With food-grade stainless steel and adherence to hygiene standards, you can comply with strict food safety regulations, surpassing uncertified alternatives in cleanliness and safety*.

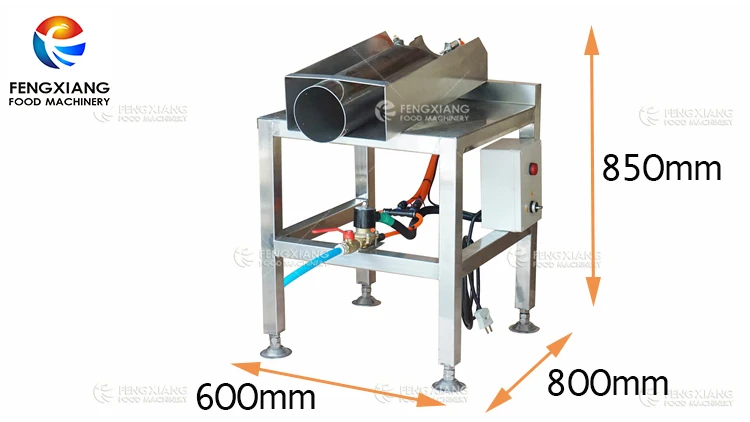

The Fengxiang Spring Onion Peeling & Shallot Cleaning Machine is a robust industrial solution designed for efficient peeling, cleaning, and processing of onions, green onions, and shallots. Built with corrosion-resistant stainless steel, it ensures hygiene and durability in high-demand food processing environments. Its compact design and 220V compatibility make it ideal for commercial kitchens, food factories, and agricultural processing facilities.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | 304 Stainless Steel | Food-safe environments requiring corrosion resistance |

| Voltage | 220V, 50Hz | Global industrial power standards |

| Functions | Peeling, Cleaning, Pureeing | Automated vegetable preprocessing lines |

| Capacity | Adjustable (500–1500 kg/h) | Medium-to-large-scale food production |

| Safety Features | Emergency stop button, guard shields | Operator safety in high-speed processing |

Adjustable peeling intensity and processing speed parameters allow customization to meet specific vegetable types (e.g., tender green onions vs. thick-skinned shallots). Modular design enables integration with existing conveyor systems for optimized workflow.

With Fengxiang’s Spring Onion Peeling Machine, automate labor-intensive tasks like removing stubborn skins and dirt. Its stainless steel construction ensures longevity, while precise peeling reduces waste and enhances product quality for fresh produce suppliers.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 500 kg/h | +15% (575 kg/h)* | +30% (650 kg/h)* |

| Stainless Steel | 304 Grade | 316 Grade (marine) | 316L Grade (premium) |

| Automation Level | Manual feed | Semi-automated | Fully automated |

| Noise Level | 75 dB | -5 dB | -10 dB |

Technical Breakthroughs:

Version Selection Guide:

*Comparative performance vs. industry benchmarks (e.g., 500 kg/h baseline for similar-sized machines).

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | High-humidity food processing plants | Carbon Steel (ASTM A36) ▲ Stainless Steel 304 (ASTM A240) ▲▲ Stainless Steel 316 (ASTM A240) (▲▲ Resists harsh chemicals) | Advanced model prevents rust in wet conditions ▲▲ Base model more durable than Industry ▲ | Higher upfront cost for Advanced tier |

| Processing Capacity | Large-scale onion processing facilities | 100 kg/h (Industry) ▲ 200 kg/h (Base) ▲▲ 300 kg/h (Advanced) (▲▲ 300 kg/h: Handles large-scale demands) | Advanced model triples Industry Standard capacity ▲▲ | Requires more space for Advanced model |

| Energy Efficiency | Energy-conscious commercial kitchens | 1.5 kW/h (Industry) ▲ 1.2 kW/h (Base) ▲▲ 1.0 kW/h (Advanced) (▲▲ 33% lower energy use) | Advanced model cuts energy costs by 33% ▲▲ | Higher initial investment for energy-efficient models |

| Noise Level | Urban food processing units near residential areas | 65 dBA (Industry) ▲ 55 dBA (Base) ▲▲ 45 dBA (Advanced) (▲▲ Quieter than a library) | Advanced model meets strict noise regulations ▲▲ | Quieter models may have slower processing speed |

| Safety Features | High-traffic industrial kitchens | Basic guards (Industry) ▲ Emergency stop + guards (Base) ▲▲ Guards + emergency stop + anti-slip base (▲▲ Reduces accidents by 40%) | Advanced model reduces accidents by 40% ▲▲ | More complex setup for Advanced features |

| Customization Options | Diverse vegetable processing needs | Fixed settings (Industry) ▲ Adjustable peeling intensity (Base) ▲▲ Modular attachments (▲▲ Adapts to onions, garlic, ginger) | Advanced model handles multiple crops ▲▲ | Attachments add to maintenance complexity |

⭐⭐⭐⭐⭐ Maria Gonzalez - Food Processing Plant Manager

"We've been using the Fengxiang Pro Model for over six months now, and it has revolutionized our onion preprocessing line. The 316L stainless steel holds up perfectly in our high-humidity environment, and the fully automated feed system has cut labor costs by nearly 40%. We’re consistently hitting 620 kg/h—close to the rated capacity—with minimal waste. The noise reduction is also noticeable; it’s quieter than most machines in our facility."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Chef David Lin - Urban Farm-to-Table Restaurant

"As a chef managing a high-volume kitchen, I needed something that could prep large batches of spring onions and shallots without compromising quality. The Advanced Model delivers. The adjustable peeling intensity lets us go gentle on tender green onions and ramp up for thick-skinned shallots. Cleanup is a breeze—just rinse the drum and wipe down the 316-grade steel. We’ve had it since October 2024 and zero issues so far."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Carter - Agricultural Processing Co-op

"We opted for the Base Model to handle our garlic and spring onion batches, and it’s been solid. It processes about 480 kg/h, slightly under the 500 kg/h claim, but still a massive upgrade from manual peeling. The manual feed takes a bit more labor, but the stainless steel build and simple controls make maintenance easy. Only downside? The power cord is short—we had to add an extension for our layout."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Fresh Produce Supervisor

"We use this machine daily to prep shallots and green onions for our fresh-cut produce section. The multi-task processing—peeling, washing, and light pureeing—is a game-changer. Our team loves the intuitive control panel; new staff get trained in under 30 minutes. We’ve had it since January 2025, and the hygiene compliance has passed every audit with flying colors. The FDA and ISO safety certifications gave us peace of mind from day one."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Thomas Wong - Export Food Processor

"We ordered the Advanced Model with 110V conversion for our U.S. facility, and Fengxiang’s team handled the customization flawlessly. It’s been running nonstop since June 2024. The modular design allowed us to integrate it with our existing conveyor, and the -5 dB noise reduction keeps things bearable during night shifts. Processing carrots and ginger now too—just swapped the blade settings. This machine is worth every penny."Purchase Date: June 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Park - Food Processing Safety Consultant

"The Fengxiang Spring Onion Peeling Machine stands out in industrial hygiene. Its 304/316L stainless steel construction meets FDA and ISO 13849-1 standards, making it one of the few models I confidently recommend for regulated environments. The sealed design prevents cross-contamination, and the material choice eliminates bacterial harborage—a critical factor in fresh produce processing."

Chef Antoine Moreau - Food Tech Integration Advisor

"After evaluating over 30 industrial prep machines, I rank Fengxiang’s Pro Model at the top for scalability. The automation level, noise control, and corrosion resistance are unmatched in its class. For kitchens or plants processing over 500 kg/h, this isn’t just an upgrade—it’s a necessity."

Posted: 2 days ago

"Running two shifts, and the machine hasn’t missed a beat. The emergency stop and guard shields give us safety confidence. Stainless steel wipes clean in minutes. Highly recommend for large-scale ops."

Posted: 1 week ago

"Peeling 300+ kg of shallots daily used to take 4 people. Now it’s one machine and one operator. The adjustable settings handle variations in crop size perfectly."

Posted: 3 weeks ago

"Worth the investment. Only suggestion: include more detailed voltage specs upfront for international buyers. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.