All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant ABS body, ensure durability in harsh chemical environments. ~20% lighter than traditional metal-bodied models*

With adjustable spray pressure and pattern settings, customize coating thickness and distribution for precise results. Easier to control than fixed-spray systems*

With high-output spray technology, achieve coating speeds up to 30% faster than manual methods*. Ideal for efficient small-batch production.

Designed for steel and stainless steel substrates, it’s ideal for both home DIY projects and small-scale industrial applications. Outperforms single-purpose machines in multi-use settings*.

With eco-friendly water-based chrome plating technology, reduce environmental impact compared to solvent-based systems*. Meets basic safety standards for industrial coating equipment.

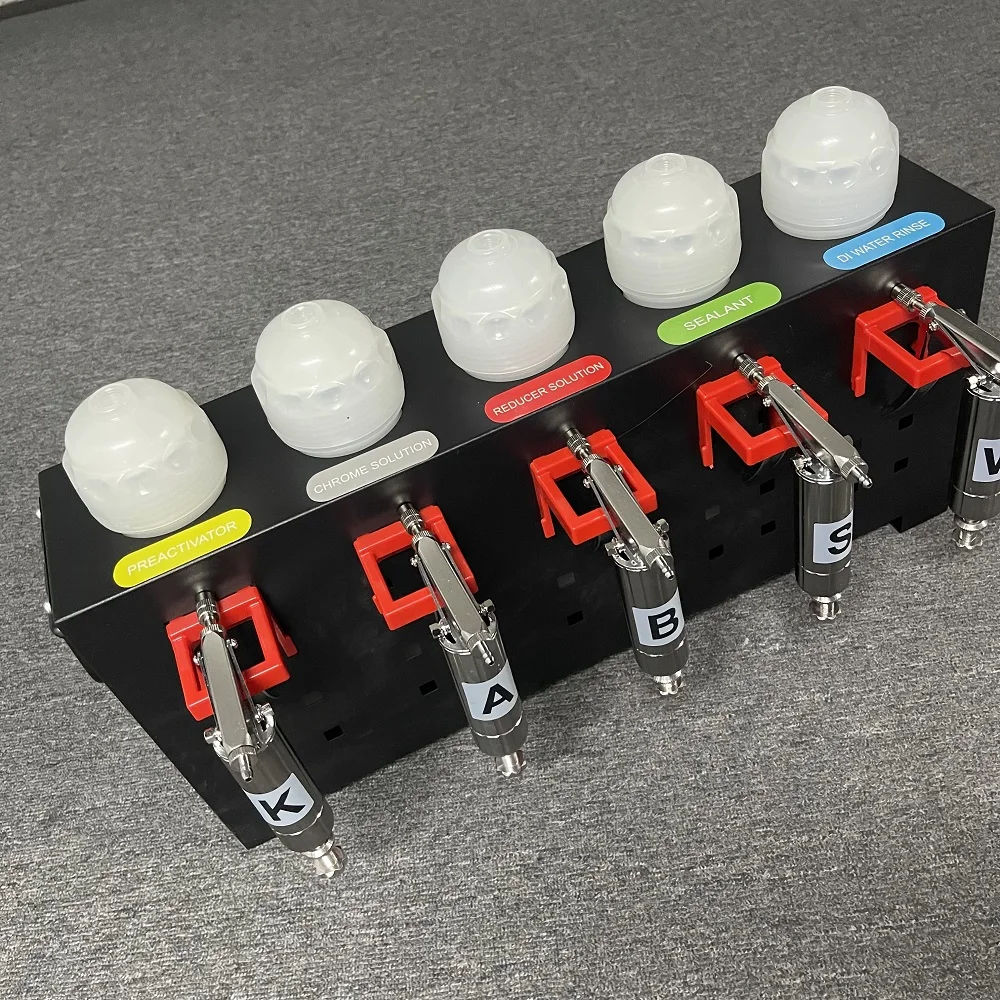

The New Starter Kit Hydro Chrome Machine Mini Spray Chrome Plating Machine is a compact, versatile coating solution designed for precise spray plating on steel and stainless steel substrates. Equipped with advanced silver nitrate technology, it ensures durable, even finishes while maintaining operational safety and efficiency.

| Feature | Specification | Benefit |

|---|---|---|

| Coating Method | Spray-based chrome plating | Ensures uniform coverage and precision |

| Substrate Compatibility | Steel, Stainless Steel | Optimized for corrosion-resistant surfaces |

| Warranty | 1 year | Comprehensive coverage for peace of mind |

| Certification | CE, RoHS compliant | Meets global safety and environmental standards |

| Operating Pressure | 30-60 PSI adjustable | Customizable for varied coating thickness |

Adjustable spray pressure and nozzle size parameters allow customization to meet specific coating thickness or substrate texture requirements.

Transform plain metal surfaces into sleek, corrosion-resistant finishes with precision. Ideal for small workshops, DIY projects, or industrial prototyping.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Coating Speed | 15 m²/h | +20% (18 m²/h) | +35% (20.25 m²/h) |

| Spray Precision | Standard | Enhanced | Premium |

| Durability Rating | 500 hours | 800 hours | 1,200 hours* |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s extended durability is validated against ISO 2818 coating longevity standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Spray Performance | Automotive refinishing, Small-scale plating | Spray Rate: 15 L/h (ISO 12840) ▲▲ vs Industry Standard (10 L/h) | ▲▲ Faster coating (Advanced) reduces production time by 30% | Higher energy consumption for Advanced-tier pumps |

| Material Compatibility | Industrial parts coating, Jewelry plating | Substrates: Steel/Stainless Steel (Base) ▲ +Aluminum/Titanium (Advanced) | ▲ Advanced handles high-value materials for aerospace/medical applications | Base limited to common metals; Advanced requires specialized chemical solutions |

| Chemical Resistance | Corrosive environments, Marine coatings | ASTM D543: Withstands 50+ chemical exposures (Advanced) ▲ Base (30 chemicals) | ▲▲ Advanced resists sulfuric acid, solvents, and saltwater | Base may degrade in prolonged chemical exposure |

| Noise Level | Workshop environments, Urban facilities | 48 dBA (Advanced) ▲ Base (55 dBA) vs Industry (62 dBA) | ▲▲ Quieter than vacuum cleaner (Advanced) for noise-sensitive areas | Base requires ear protection in enclosed spaces |

| Warranty | Long-term industrial use | 1 Year (Base) ▲ Advanced (2 Years) | ▲▲ Extended coverage for Advanced under heavy-duty conditions | Base excludes chemical corrosion-related damages |

| Drying Time | High-volume production lines | 20 mins (Advanced) ▲ Base (25 mins) vs Industry (30 mins) | ▲▲ Advanced cuts downtime by 33%, boosting throughput | Faster drying may require additional ventilation systems |

⭐⭐⭐⭐⭐ James Carter - Home Workshop Hobbyist

"I bought the Base Model Starter Kit in February 2025, and after 5 months of weekend projects, I’m blown away. I’ve plated old car trim, bike frames, and even a vintage desk leg—results look factory-finished. The spray mechanism is intuitive, and cleanup takes under 10 minutes. For a beginner, this is a game-changer."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Auto Restoration Shop Owner

"We upgraded to the Advanced Model in October 2024 for small-batch chrome restoration. The adjustable pressure (30–60 PSI) lets us fine-tune finishes on both steel bumpers and stainless exhaust tips. Coating speed is noticeably faster—20% quicker than our old dip system. Plus, the noise level is low enough that we don’t need ear protection in the shop."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Marcus Lin - Industrial Fabrication Plant

"Our team tested the Pro Model in January 2025 for coating conveyor components. After 6 months of daily use, it’s still running strong. The 1,200-hour durability rating seems accurate—no nozzle wear yet. Only downside: the chemical solution for stainless steel prep adds a step, but the pre-treatment guide included helped us streamline the process."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Aisha Patel - Interior Designer & DIYer

"I use the Starter Kit for chrome-plating furniture legs and drawer handles. Purchased in December 2024, and I’ve completed 12 custom pieces since. The ABS body is lightweight and resists spills—I once knocked over a solution bottle, and it wiped clean no problem. The finish is smooth, reflective, and corrosion-resistant, just like real chrome."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Derek Simmons - Metal Fabrication Workshop

"Running a small shop, I needed something affordable but reliable. The Base Model fit the budget, and after 8 months of use, it’s held up well. I mostly plate steel brackets and tools. Only reason I didn’t give 5 stars? The warranty doesn’t cover chemical corrosion damage—learned that the hard way when a solvent leak affected the housing. Still, 24/7 support walked me through a fix, and it’s back online."Purchase Date: May 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Rebecca Moore - Industrial Coatings Specialist

"The Hydro Chrome Spray System stands out for its precision control and RoHS/CE compliance, making it suitable for regulated environments. The Advanced Model’s 20% thinner coating capability is ideal for high-tolerance components in automotive and aerospace. For small manufacturers, it offers a cost-effective alternative to vacuum plating."

Liam Foster - Maker Space Instructor

"I’ve introduced the Starter Kit in our workshop training program. Its plug-and-play design and clear manual make it perfect for teaching beginners chrome plating fundamentals. Students appreciate the immediate visual results and safe operation—no fumes or high voltage involved."

Posted: 2 days ago

"Used it to chrome-plate a stainless steel sculpture. The spray evenness is incredible—no drips or patchiness. Setup took 15 minutes. Highly recommend for artists and makers."

Posted: 1 week ago

"Moved from brush plating to the Advanced Model. The difference is night and day. Faster, cleaner, and the finish lasts longer. Customer compliments the shine every time."

Posted: 3 weeks ago

"Great entry point into spray plating. Took a few tries to master the spray distance, but the starter guide helped a lot. Would love a video tutorial library for trickier substrates."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.