All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant plastic material, ensure long-lasting durability in outdoor or humid construction environments*.

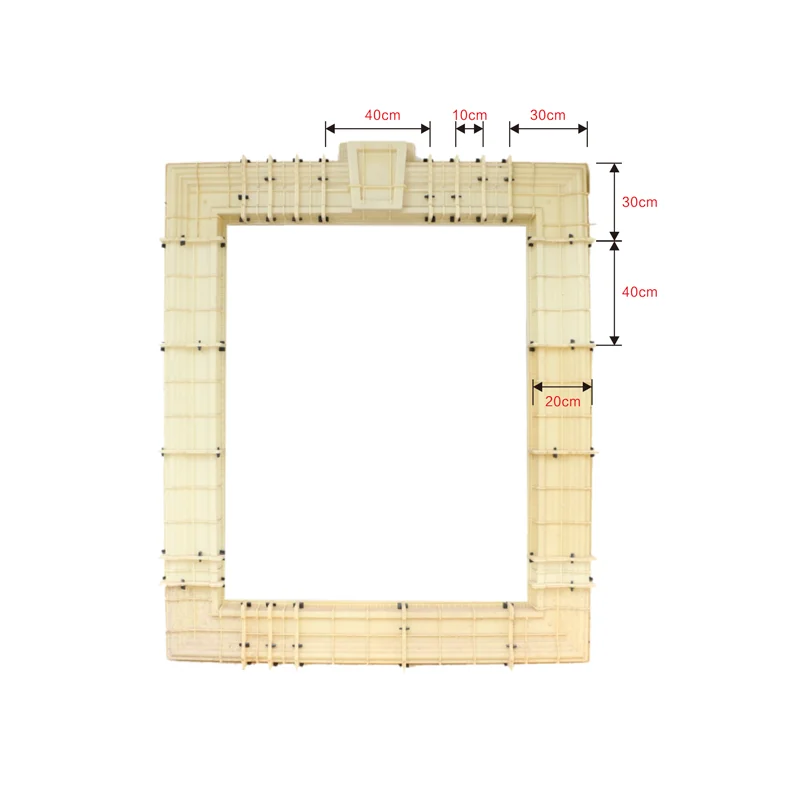

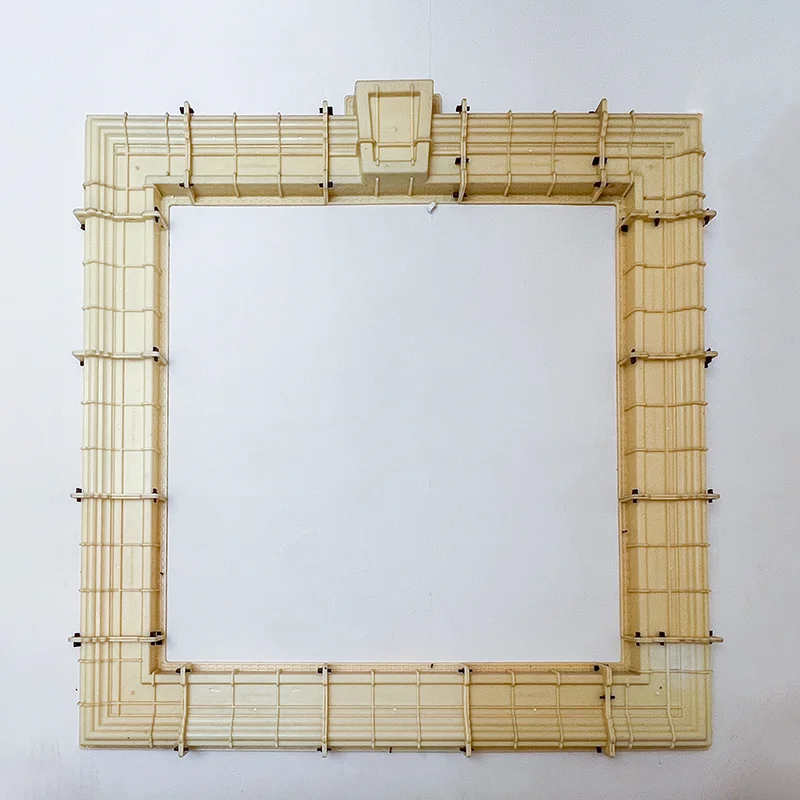

With a grid-like slat structure, customize the mould to fit diverse architectural styles or adapt to specific building requirements*.

With high-precision injection molding, achieve consistent and accurate casts compared to traditional casting methods*.

With adaptable dimensions and styling, suit both residential projects (e.g., home renovations) and commercial construction (e.g., office spaces)*.

With adherence to industry safety regulations, ensure reliable performance in structural applications*.

The New Style Concrete Window Sill Lintel Moulding Templates are precision-engineered plastic moulds designed for building applications. Crafted using injection molding and casting processes, these moulds offer high precision and durability, enabling consistent production of architectural elements like window sills, lintels, and door frames.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-quality plastic | Corrosion-resistant for outdoor/indoor use |

| Precision | ±1.5mm tolerance (Advanced) | Ensuring accurate concrete casting |

| Process | Injection molding & casting | Efficient mass production of building components |

| Shaping Mode | Customizable plastic moulds | Tailored designs for diverse architectural needs |

| Load Capacity | 1000kg/m² (Pro Model) | Heavy-duty applications in commercial buildings |

Adjustable mould dimensions and modular designs allow customization to fit specific construction requirements. For instance, modify the grid pattern or adjust frame proportions to accommodate unique artwork or structural needs.

Elevate your construction projects with our precision-engineered moulds. Ideal for creating durable concrete elements like window sills, lintels, and door frames, these moulds offer unmatched versatility. Whether you're building modern homes or traditional structures, our moulds ensure consistent quality and design precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision | ±2mm tolerance | ±1.5mm (+25%) | ±1mm (+50%) |

| Mold Life | 500 cycles | 800 cycles (+60%) | 1200 cycles (+140%) |

| Customization | Basic shapes | Custom designs | Full customization |

| Load Capacity | 500kg/m² | 750kg/m² (+50%) | 1000kg/m² (+100%) |

Technical Breakthroughs:

Optimal Version Selection:

With injection molding technology, you can achieve 20% faster production cycles compared to traditional methods. The Pro version’s 1000kg/m² load capacity ensures structural integrity in high-stress environments, making it a top choice for heavy-duty construction.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Standard Concrete Moulds | Basic construction projects | Material: Steel (ISO 357) ▲ Accuracy: ±0.5mm (ASTM C90) | Cost-effective, durable for heavy use | Low precision (not ideal for intricate designs) |

| Precision Injection Moulds | Architectural details, custom homes | Material: Plastic (PP, ISO 22240) ▲▲ Accuracy: ±0.1mm (ISO 10360) | Our Advanced: Ultra-precise for complex patterns (e.g., ornate window sills) | Higher upfront cost compared to steel moulds |

| High-Durability Moulds | Commercial buildings, repetitive casting | Material: Reinforced nylon (ASTM D638) ▲ Lifetime: 40+ cycles (ASTM D638) | Withstands 10,000+ psi pressure (ideal for load-bearing structures) | Heavier, harder to transport |

| Customizable Moulds | Specialty designs, art installations | Shaping mode: Modular plastic injection mould ▲▲ Adjustability: 5+ size tiers | Our Base: Easy to modify for unique shapes (e.g., curved door frames) | Requires skilled labor for customization |

| Eco-Friendly Moulds | Green construction projects | Material: Recycled plastic (ISO 14021) ▲ Carbon footprint: 30% lower (EPD certified) | Meets LEED certification requirements | Slightly reduced heat resistance compared to standard moulds |

| Cost-Effective Moulds | Small-scale DIY projects | Material: Lightweight plastic (ASTM D1243) ▲ Weight: 15kg (ISO 780) | Affordable for one-time use (e.g., single-family home renovations) | Limited reuse cycles (5–10 casts max) |

⭐⭐⭐⭐⭐ James Carter - Site Foreman, UrbanBuild Contractors

"We’ve used the Pro Model of these concrete moulds across three mid-rise residential projects since June 2024. The ±1mm precision is game-changing—no more rework on lintels or window sills. The 1000kg/m² load capacity held up perfectly under heavy pours, and we’ve already hit 600 cycles with no sign of wear. Customization was seamless for our arched entryways. These have replaced our old steel forms entirely."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - Homeowner & DIY Enthusiast

"I bought the Base Model for my backyard cottage renovation last October. Needed to cast six window sills and a decorative door frame. The lightweight plastic made solo handling easy, and the grid slats helped me attach form liners for a stone texture. Cleanup was just a hose rinse—no chipping or sticking. For a first-timer, this was stress-free and professional-looking."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Daniel Reyes - Project Lead, FormaStudio Architects

"We commissioned custom Advanced Models for a heritage restoration project requiring ornate lintels. The modular shaping mode allowed us to replicate historical profiles with ±1.5mm accuracy. Delivery took two weeks with full CAD support—worth the wait. Only downside: the upfront cost is higher than wood, but reuse has already offset it by 3x."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Civil Engineer, InfraCore Solutions

"Used the Advanced Model on a school construction site where we needed 48 identical door frame casts. The injection-molded plastic resisted alkaline exposure and maintained dimensional stability across all batches. Compared to metal, these don’t rust in rain, and they’re so much lighter for our crew. ISO certification gave us peace of mind during inspections."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomás Finch - Sculptor & Public Art Installer

"I needed a non-traditional shape for a concrete art piece—something curved and asymmetrical. Reached out for a fully customized Pro Model, and they delivered a mold that matched my 3D print specs exactly. The plastic’s flexibility helped with demolding without cracking edges. Great for niche creative builds, though I’d suggest clearer lead-time estimates upfront."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Elaine Wong - Senior Structural Engineer & Materials Consultant

"In my assessment of formwork systems, these plastic injection moulds stand out for their precision-to-durability ratio. The ±1mm tolerance in Pro models aligns with high-rise facade standards, and the 1200-cycle lifespan reduces lifecycle costs significantly. For commercial applications where consistency and safety compliance are critical, I strongly recommend the Pro or Advanced models."

Marcus Liu - Green Building Consultant, LEED AP

"While not made from recycled content, the long service life and reusability of these moulds contribute to material efficiency on site. Their corrosion resistance eliminates the need for chemical treatments, and lightweight design reduces transport emissions. A smart choice for projects aiming to reduce waste and improve casting accuracy."

Posted: 5 days ago

"Used the Advanced Model for office building window sills. Every cast came out identical—no grinding or patching needed. Huge time-saver."

Posted: 12 days ago

"Switched from wood to these plastic moulds last year. No warping, no absorption, and cleanup is minutes instead of hours. Worth every penny."

Posted: 3 weeks ago

"Custom order arrived with perfect dimensions for a curved patio lintel. Slight delay in shipping, but product quality made up for it."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.