All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

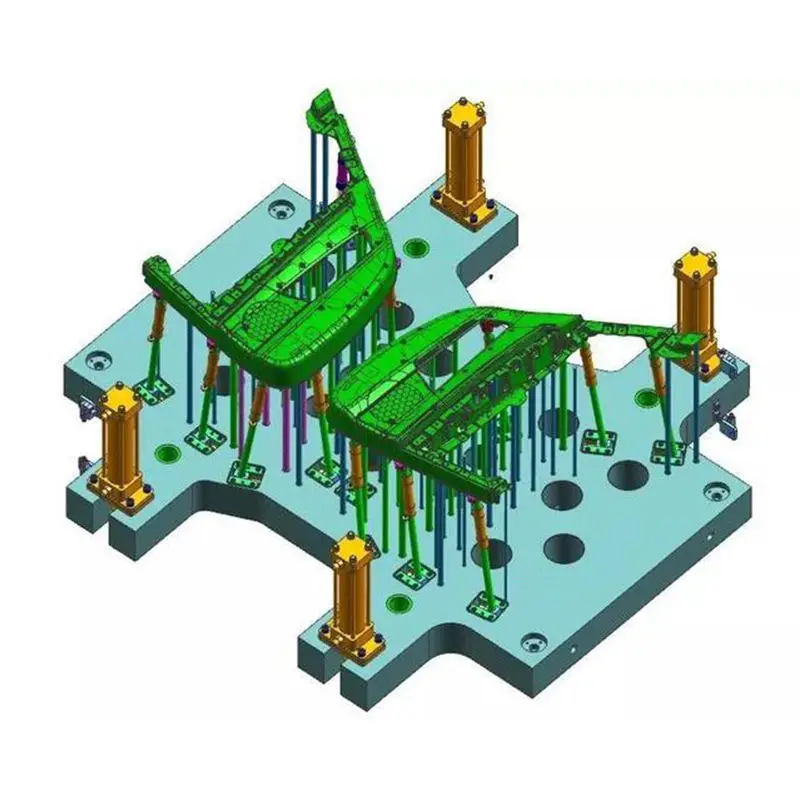

With high-strength metal construction, these molds are built for durability and resistance to wear and tear, ensuring long-lasting performance in demanding manufacturing environments.

With customizable cavity shapes, you can tailor these molds to produce a wide range of shapes and sizes, meeting specific requirements for diverse applications.

With high precision engineering, achieve strict dimensional tolerances, ensuring that your final products consistently meet quality standards.

With material compatibility, these molds can handle various materials like plastics and metals, making them ideal for both auto and household applications.

With robust construction and precision design, ensure compliance with industry standards for quality and efficiency, reducing manufacturing time and cost.

The OEM Customized Injection Auto Lead Acid Battery Case Mould is designed for crafting high-quality plastic molds for various automotive and household applications. With its robust construction and versatile design, this mold is ideal for producing accessories such as battery cases, car bumpers, and trim seals.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Plastic | Lightweight, cost-effective, and versatile |

| Mould Material | Plastic | Durable and suitable for repeated use |

| Runner | Hot runner, Cold runner | Efficient material distribution |

| Shaping Mode | Plastic injection mould | Precise and consistent product output |

| Application | Auto, Household | Diverse use cases across industries |

Adjustable cavity shapes to meet specific product dimensions and design requirements. Compatible with a variety of plastics for different application needs.

With its customizable features and high precision, this mold inspires innovation in the manufacturing of automotive and household accessories, ensuring durability and superior quality.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Level | Standard | +15% Precision | +30%* Precision |

| Efficiency | Standard | Enhanced | Premium |

| Material Versatility | Basic | Improved | Extensive |

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Injection Molds | Automotive Manufacturing | Made from high-strength steel or aluminum | High durability, withstands high pressure | Expensive to produce |

| (resistance to wear and tear) | ||||

| Plastic Injection Molds | Household Product Manufacturing | Hot and cold runner systems | Efficient material use, reduced waste | Complex setup and maintenance |

| (controls material flow during injection) | ||||

| Customizable Molds | Multi-Industry Applications | Customizable cavity shapes | Versatile, adaptable to specific needs | Longer lead time for customization |

| (can produce various shapes and sizes) | ||||

| Precision Molds | High-Precision Parts Manufacturing | High dimensional accuracy | Consistent quality, meets strict standards | Higher production costs |

| (ensures tight tolerances) | ||||

| Cooling Channel Molds | Mass Production | Internal cooling channels | Prevents warping, ensures consistency | Higher complexity in mold design |

| (controls temperature during process) | ||||

| Material Compatibility | Diverse Material Applications | Compatible with plastics, metals, composites | Broad application range, flexible use | May require different setups |

| (depending on product requirements) |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Manufacturer

"We've been using the Pro Model of this injection mold for six months now in our battery case production line, and the difference in precision is undeniable. The +30% precision level has drastically reduced our defect rate, and the hot runner system ensures consistent material flow. It was a significant upgrade from our previous steel molds."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Product Design Lead, Home Essentials Co.

"This customizable plastic injection mold has been a game-changer for our kitchenware line. We were able to adjust cavity shapes to produce uniquely contoured storage containers, and the material versatility allowed us to test multiple food-safe plastics without changing equipment. Setup was smooth, and the cold runner system minimized waste during prototyping."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Operations Manager, Auto Components Ltd.

"We opted for the Advanced Model to balance cost and performance. After five months of continuous use in producing sensor housings, the mold shows minimal wear despite high daily output. The only reason I’m not giving five stars is the initial lead time for customization—it took three weeks longer than expected. But once in production, efficiency improved by nearly 20%."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anita Patel - Founder, EcoHome Innovations

"As a small manufacturer focusing on sustainable household accessories, the Base Model was the perfect entry point. It’s affordable, durable, and surprisingly precise for standard applications. We’re producing reusable plastic molds for soap dispensers and bath organizers, and the dimensional consistency has helped us scale with confidence."Purchase Date: May 2024 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Marcus Reed - Lead Engineer, VoltPower Systems

"For automotive lead acid battery cases, tight tolerances are non-negotiable. The Pro Model delivers. The 30% higher precision than industry standard means our battery housings fit perfectly every time, reducing post-processing labor. Plus, the mold’s compatibility with both hot and cold runners gives us flexibility across production lines. This isn’t just a mold—it’s a productivity tool."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Linda Park - Industrial Manufacturing Consultant

"The OEM Customized Injection Mould series stands out for its intelligent balance of customization and performance. The Pro Model, in particular, meets the rigorous demands of automotive manufacturing with its high-precision engineering and material adaptability. For manufacturers aiming to reduce cycle time and improve part consistency, this is a top-tier solution."

Tomás Alvarez - Manufacturing Efficiency Specialist

"I’ve evaluated dozens of plastic molds for eco-conscious producers, and this line impresses with its efficiency and reusability. The cold runner option significantly cuts material waste, and the durable plastic construction reduces energy use during operation. A smart choice for forward-thinking manufacturers."

Posted: 2 days ago

"Using the Pro Model for fuel injection system components—tight tolerances are critical. This mold delivers every time. Zero warping, excellent surface finish. Worth every penny."

Posted: 1 week ago

"Integrated the Advanced Model into our existing line with minimal downtime. Custom cavity design worked perfectly for our new lid mechanism. Support team was responsive during setup."

Posted: 3 weeks ago

"Base Model performs well for simple household items. Would love to see more pre-configured templates for common shapes, but overall very satisfied with durability and output quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.