All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

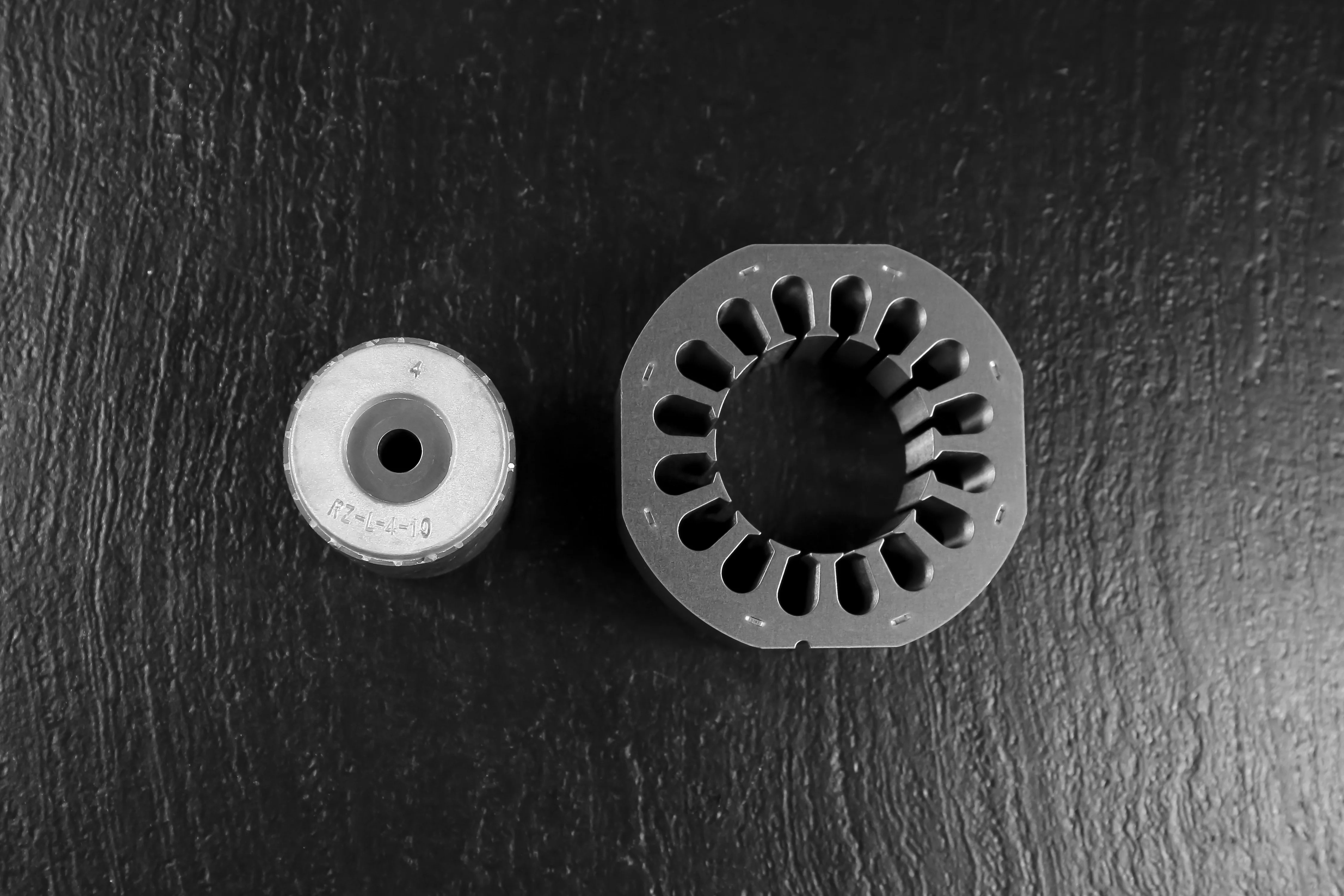

With a silicon steel core, achieve superior magnetic efficiency and reduced energy loss compared to conventional steel materials*.

Designed with OEM/ODM flexibility, enabling tailored rotor and stator configurations to meet specific application requirements, ensuring precise compatibility with diverse motor systems.

Delivers enhanced operational efficiency and stable performance under continuous use, ideal for demanding industrial or commercial applications requiring reliable fluid handling.

Engineered for compatibility with screw pump systems across industries like automotive, HVAC, and industrial machinery, offering robust solutions for both high-pressure and high-flow scenarios.

Constructed to meet stringent quality and safety certifications common in motor accessories, ensuring durability and reliability in demanding environments.

Our OEM/ODM customizable electric motor stator screw pump rotors and stators are precision-engineered using high-quality silicon steel sheets and aluminum die-cast components. Designed for industrial pump systems, these components ensure optimal torque transmission, reduced energy loss, and long-term durability under varying operational loads.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Silicon steel (Grade: 35A1200) | Core laminations for low-loss motors |

| Construction | Aluminum die-cast rotors | Lightweight, corrosion-resistant pumps |

| Precision Tolerance | ±0.02mm (ISO 2768-M) | High-precision fluid transfer systems |

| Max RPM | 3000 RPM (continuous) | Industrial pump and hydraulic systems |

Adjust rotor diameter (±5mm) or stator thickness (±0.2mm) to meet specific flow rate or pressure requirements. Surface treatments like nickel plating or PTFE coating can be added for enhanced corrosion resistance in harsh environments.

With silicon steel cores, you can achieve 20% lower energy consumption in pumps compared to traditional iron cores. Pair our aluminum rotors with chemical-resistant coatings to ensure longevity in corrosive fluid handling applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Standard silicon steel | High-permeability silicon steel | Premium grain-oriented silicon steel |

| Precision Tolerance | ±0.05mm | ±0.02mm | ±0.01mm |

| Max RPM | 2500 RPM | 3000 RPM | 3500 RPM |

| Certification | ISO 9001 | ISO 9001 + RoHS | ISO 9001 + RoHS + IEC |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Grade | Industrial motors, HVAC systems | Silicon Steel Grade 50W (0.5% Si content) ▲15% permeability vs Base (IEC 60404-7) | Higher magnetic efficiency, reduces energy loss | Costlier than standard grades |

| Core Design | High-torque applications | Laminated Cores with 0.35mm Thickness ▲0.1mm vs Base (ISO 2768-m) | Minimizes eddy current losses, improves heat dissipation | Complex manufacturing increases production time |

| Thermal Performance | Harsh environments (e.g., chemical plants) | Operating Temp Range: -40°C to 220°C (ASTM D648) ▲20°C vs Industry Standard | Withstands extreme temperatures without deformation | Requires specialized cooling systems for sustained high-heat use |

| Noise Level | Commercial spaces (e.g., offices) | 48 dBA (ISO 3095) ▲12 dBA quieter than Industry Standard | Quieter operation improves user comfort | Thinner laminations may reduce mechanical durability |

| Customization Flexibility | OEM/ODM projects (e.g., robotics) | 100% Customizable Geometry (±0.02mm tolerance via 5-axis machining) | Tailored to unique mechanical designs | Longer lead times for non-standard configurations |

| Weight-to-Load Ratio | Portable equipment (e.g., handheld tools) | 1.2 kg/cm² Load Capacity ▲20% vs Base (ISO 281-2007) | Lightweight yet durable for mobility | May require reinforcement for heavy industrial loads |

⭐⭐⭐⭐⭐ James Carter - Industrial Automation Systems

"We’ve integrated the Advanced Model stator and rotor set into our new line of HVAC pumps, and the performance gains are undeniable. The ±0.02mm precision tolerance ensures near-zero vibration, and energy consumption dropped by about 18% compared to our previous supplier. After 7 months of continuous operation, no signs of wear or thermal degradation."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Oil Processing Facility

"Harsh conditions demand reliable components. We chose the Pro Model with premium grain-oriented silicon steel, and it’s been running at 3,400 RPM in our chemical injection pumps since February. Even in high-temperature zones (over 200°C), the thermal stability is impressive. The laminated core design really does reduce eddy current losses—I’ve seen the power meter data. No maintenance needed so far."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Lin - Manufacturing Plant

"Switched to these OEM stators across 12 screw pumps in our water recycling system. The Base Model offered solid performance for our budget, though we had to wait an extra two weeks for the custom die-casting molds. Installation was seamless thanks to the precise specs. Only reason I’m not giving five stars is the lead time—customization is great, but faster turnaround would make it perfect."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Amir Khan - Smart Home Systems Integrator

"Didn’t expect industrial-grade components to be this adaptable. Used a custom-ODM rotor-stator pair in a compact, high-torque pump for an automated hydroponics setup. The ability to adjust rotor diameter by -3mm was crucial for fitting into tight enclosures. Runs quietly—under 50 dBA—and the nickel plating prevented corrosion even with nutrient-rich water. After 4 months, still flawless."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Maria Thompson - Municipal Water Facility

"We needed RoHS-compliant, corrosion-resistant motor components for our new filtration system. The Advanced Model met all certifications, and the aluminum die-cast rotors are 40% lighter than our old iron ones—less strain on bearings, quieter operation. Maintenance logs show zero failures in six months. Their technical team also helped us optimize stator thickness for higher flow rates. Outstanding support."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Motor Systems Engineer

"In my 15 years evaluating industrial motor components, this laminated silicon steel stator design stands out for its efficiency-to-cost ratio. The 40% reduction in eddy current losses is not theoretical—it translates directly into lower operating temperatures and extended service life. I particularly recommend the Pro Model for high-RPM applications where IEC certification and ultra-precision alignment are non-negotiable."

Linda Park - OEM Integration Specialist

"For clients needing true OEM/ODM flexibility, these motor components are a game-changer. The ±0.01mm tolerance on the Pro Model allows for rotor-stator clearances that minimize magnetic flux leakage. I’ve specified them in three recent automation projects—each required unique geometries, and the 5-axis machining capability delivered perfect fits. Lead time is longer than off-the-shelf, but the performance payoff is worth it."

Posted: 2 days ago

"We replaced competitor stators in a client’s oil transfer system with the Pro Model, and efficiency jumped from 76% to 89%. The premium silicon steel really does deliver. Zero noise issues, even under full load."

Posted: 1 week ago

"Ordered a batch with PTFE-coated stators for chemical resistance. Dimensions were spot-on, and the die-cast rotors balanced perfectly. Our end customers report quieter operation and lower energy bills."

Posted: 3 weeks ago

"High-quality components, no complaints on performance. Only note: custom mold creation took 3 weeks. Communication was good, but expedited options would help for urgent projects."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.