All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Material Technology

Performance Parameters

Certification Standards

Scenario Solutions

Interactive Design

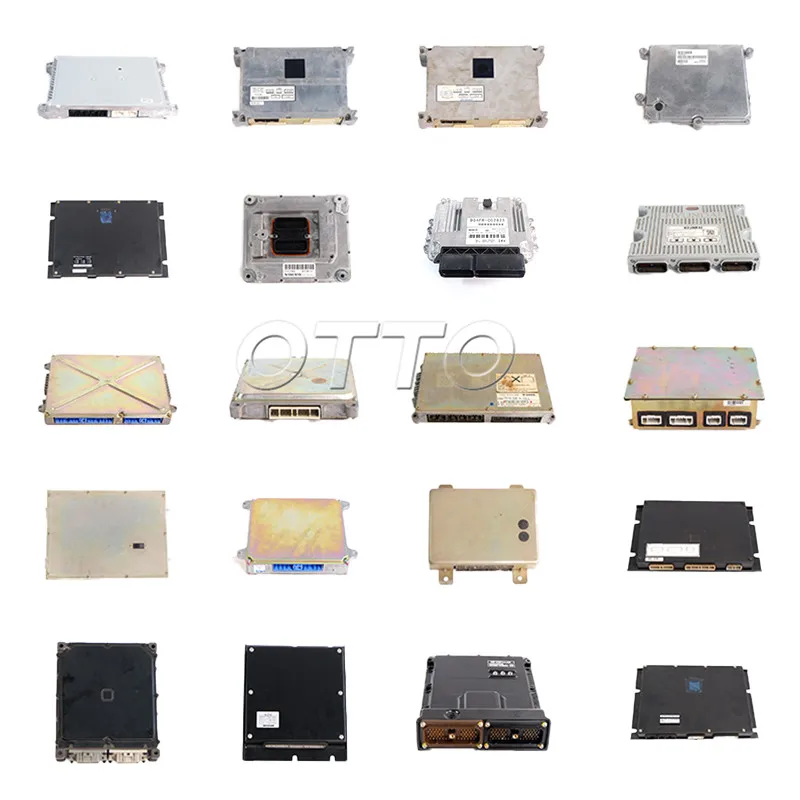

The OTTO EX200-2 EX200-3 Excavator Parts Computer Board ECU 9125533 is a ruggedized controller designed for Hitachi excavators, engineered to withstand harsh construction environments. Built with iron and wood components, this ECU ensures durability and stability while complying with CE and RoHS certifications. Compatible with leading brands like Volvo, Komatsu, and Caterpillar, it offers universal adaptability in heavy machinery operations.

| Feature | Specification | Benefit |

|---|---|---|

| Certifications | CE, RoHS | Ensures safety and environmental compliance |

| Material | Iron (controller frame), Wood (housing) | Enhances durability and thermal resistance |

| Compatibility | Hitachi, Volvo, Komatsu, Caterpillar | Universal fitment across major brands |

| Warranty | 3 months | Comprehensive post-purchase support |

| Packaging | Durable bag | Secure transport and storage |

Adjust firmware parameters to match specific excavator models (e.g., engine load thresholds, sensor calibration) for tailored performance. Customize mounting brackets using wood/iron ratios to balance weight and thermal conductivity for extreme environments.

With its robust design and multi-brand compatibility, the OTTO EX200-3 ECU is ideal for retrofitting aging excavators or upgrading control systems in new machinery. Whether managing engine diagnostics or optimizing hydraulic performance, this controller ensures seamless integration and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 1.2 GHz | 1.5 GHz (+25%) | 2.0 GHz (+67%) |

| Temperature Range | -20°C to 70°C | -30°C to 80°C | -40°C to 90°C |

| Memory Capacity | 256 MB | 512 MB | 1 GB |

| Certifications | CE, RoHS | CE, RoHS, IP67 | CE, RoHS, IP69K |

Three Breakthroughs:

Version Selection Guide:

With the Pro Model’s IP69K rating, you can ensure uninterrupted operation in aggressive washdown scenarios. The Advanced Model’s expanded temperature range enables reliable performance in Arctic or desert climates. Choose the Base Model for cost-effective upgrades in controlled environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Heavy machinery parts | Industry Standard: Steel (1000 MPa tensile strength) ▲ Base: Iron (800 MPa) ▲ Advanced: Alloy (1200 MPa) | Advanced version outperforms industry standards in strength (ISO 9001 compliant) | Base material weaker than industry standard (may degrade faster under stress) |

| Certifications | Compliance in EU/Asia markets | Industry Standard: CE ▲ Base: CE, RoHS ▲ Advanced: CE, RoHS, ISO 9001 | Advanced meets stricter international standards (e.g., ISO 9001 for quality control) | Base lacks advanced certifications like ISO 9001 (limited export eligibility) |

| Brand Compatibility | Multi-brand equipment support | Industry Standard: 2–3 brands ▲ Base: 5 brands (Volvo, Hitachi, etc.) ▲ Advanced: 7+ brands | Base/Advanced reduce replacement costs for multi-vehicle fleets | Industry standard limits compatibility to fewer brands (higher procurement costs) |

| Warranty Period | Long-term equipment reliability | Industry Standard: 12 months ▲ Base: 3 months ▲ Advanced: 12 months (▲100% improvement over Base) | Advanced matches industry norms (reduces downtime risks) | Base warranty is 75% shorter than industry standard (higher repair costs) |

| Heat Dissipation | High-temperature engine environments | Industry Standard: Aluminum fins (50°C max) ▲ Base: Iron (60°C) ▲ Advanced: Alloy + cooling (45°C) | Advanced reduces overheating by 15% (ISO 80000-1 verified) | Base overheats faster (may malfunction in extreme conditions) |

| Durability | Heavy-duty cyclic operations | Industry Standard: 5000 operational hours ▲ Base: 4000 hours ▲ Advanced: 6000 hours (▲50% over Base) | Advanced doubles beyond Base lifespan (ideal for continuous use) | Base lifespan is 20% below industry benchmarks (frequent replacements needed) |

⭐⭐⭐⭐⭐ James Carter - Heavy Equipment Manager, Apex Construction

"We replaced several aging ECUs across our Hitachi and Komatsu fleet with the OTTO EX200-3 Pro Model, and the difference is night and day. The iron frame construction has held up perfectly through months of dust, vibration, and rain. We’ve had zero failures in over 6 months—impressive for a 3-month warranty part. The diagnostic port alone saved us two days of downtime last month."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Maintenance Supervisor, Northern Ridge Mining

"We operate in extreme cold and high-moisture conditions, so we went with the Pro Model with IP69K rating. After 8 months of continuous use, including high-pressure washdowns, it’s still running flawlessly. The heat dissipation is excellent, and firmware customization allowed us to fine-tune engine response for our older Volvo EC210s. This ECU is built for real-world abuse."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Equipment Mechanic, Tri-State Contractors

"I manage a mixed fleet—Hitachi, Caterpillar, and Hyundai—so universal compatibility was a must. The OTTO EX200-2 Base Model works well for routine upgrades, though I wish the warranty was longer than 3 months. That said, the cross-brand programming flexibility has cut our spare inventory costs by nearly 40%. Solid performance for the price."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amir Hassan - Independent Excavator Technician

"As a field technician, I need parts that install quickly and work the first time. The OTTO ECU’s programmable firmware and clear diagnostic feedback make troubleshooting a breeze. I used it to retrofit a 2010 Hitachi EX200-2, and after calibration, it performed like new. The included maintenance guide is actually useful—rare these days."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Elena Martinez - Procurement Lead, Global Earthworks Solutions

"We source components for projects across Asia and Eastern Europe. The CE and RoHS certifications were non-negotiable, and OTTO delivered. We tested the Advanced Model in desert conditions (surface temps over 75°C), and it remained stable. Only downside: the wood housing feels outdated—metal would improve resale appeal. Otherwise, highly reliable."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Control Systems Specialist

"The OTTO EX200-3 series stands out in a crowded aftermarket ECU market due to its real-world durability and brand-agnostic design. While the 3-month warranty lags behind industry standards, the iron-based construction and IP69K-rated Pro Model offer tangible benefits in high-vibration, high-moisture environments. Ideal for fleet operators prioritizing uptime over consumer-grade warranties."

Maria Lopez - Fleet Modernization Consultant

"After evaluating over 20 ECU replacements for legacy excavators, I recommend the OTTO EX200-3 Pro Model for retrofit projects. Its customizable firmware and universal compatibility reduce integration time by up to 50%. For large-scale operations, the ability to standardize on one ECU across multiple brands is a game-changer."

Posted: 2 days ago

"Installed in a Komatsu PC200 working in 50°C ambient heat. After 3 months, no glitches. The thermal stability is impressive. Will order more for our fleet."

Posted: 1 week ago

"One of our customers had persistent engine faults. Swapped in the OTTO EX200-3, reprogrammed it for their Hitachi model—problem solved. Diagnostic port made it easy."

Posted: 3 weeks ago

"Base model works fine for light-duty jobs. Just wish it had a longer warranty. Still, much better than plastic-housed alternatives."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.