All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

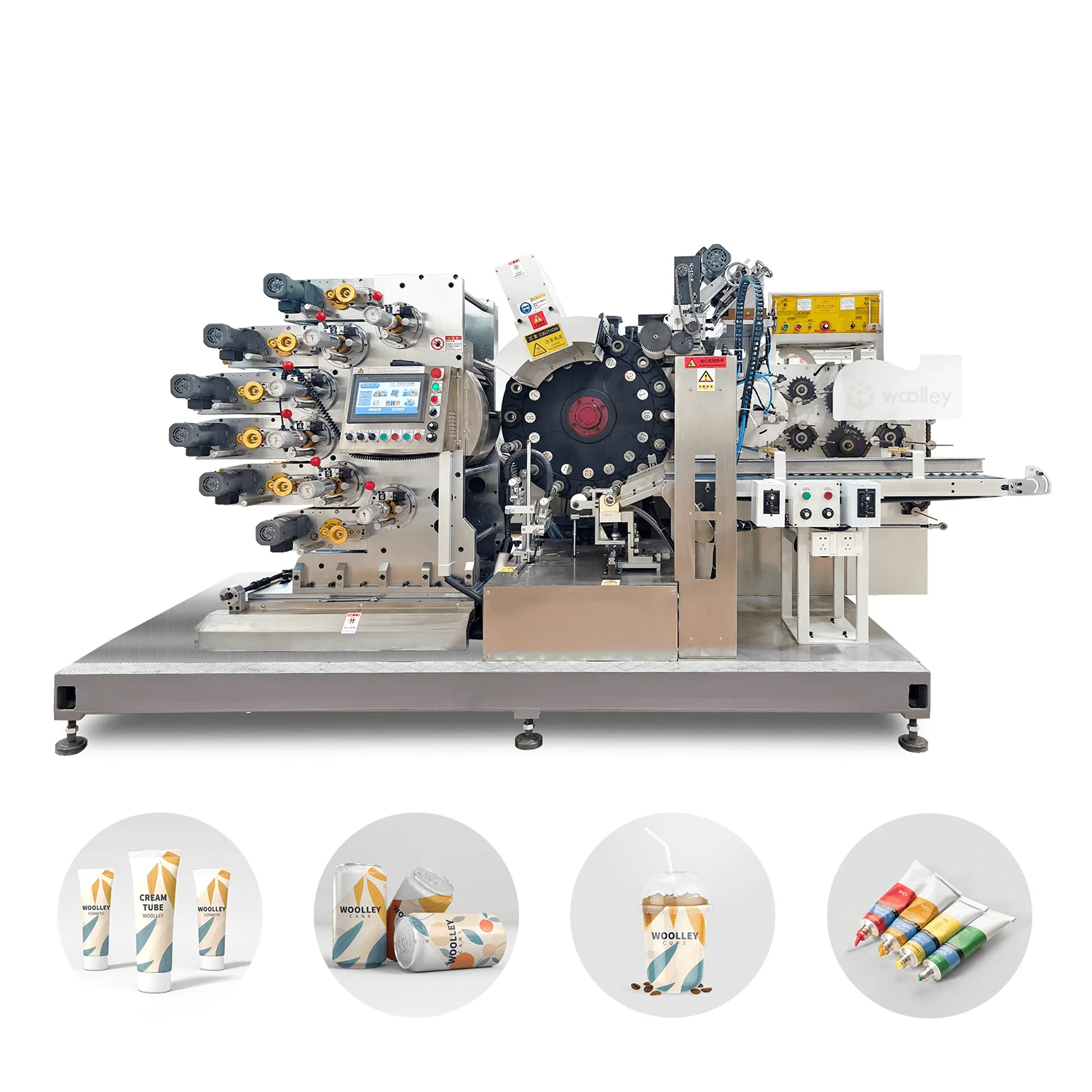

With corrosion-resistant alloy construction, you can ensure durability in high-volume industrial environments.

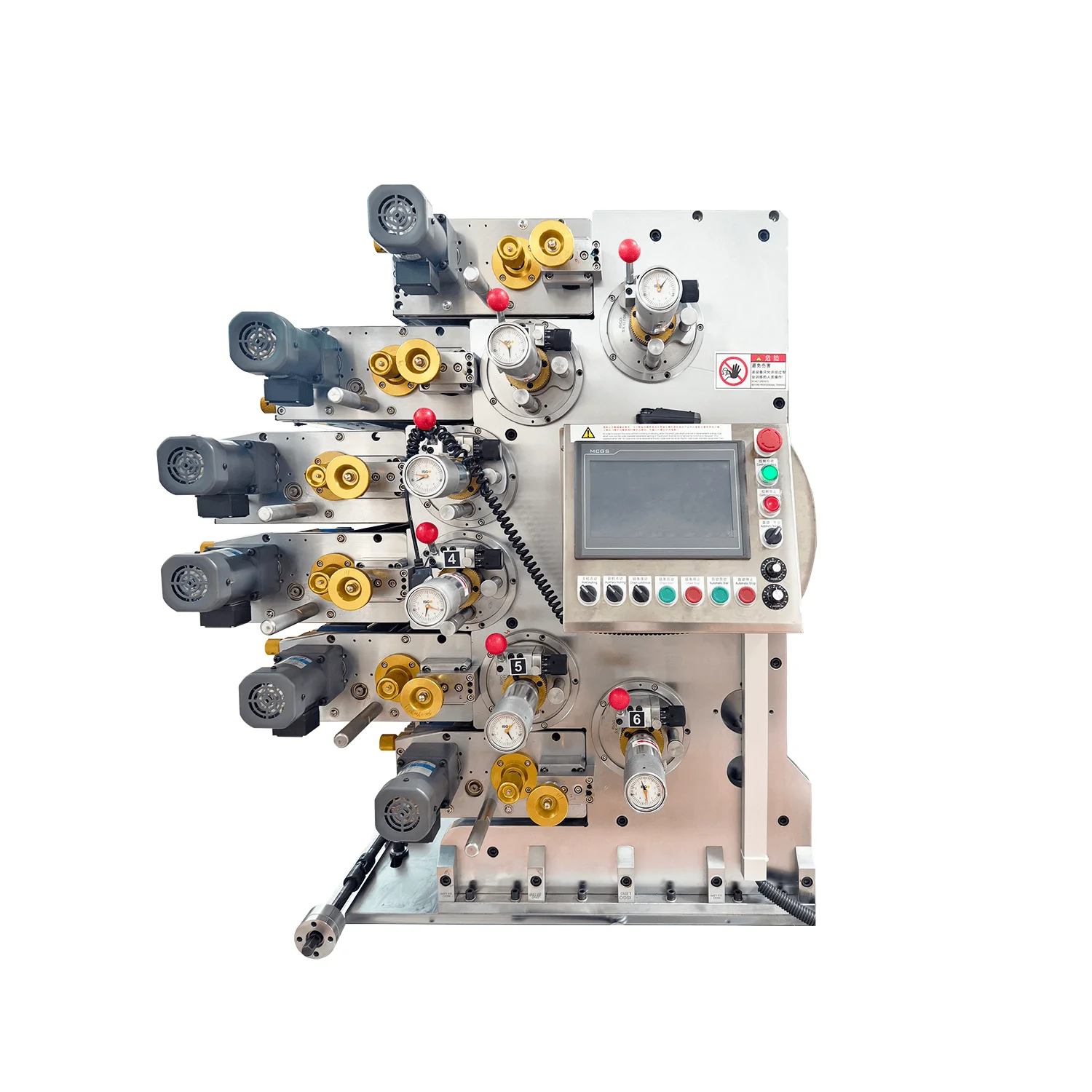

With a programmable touchscreen interface, you can customize printing presets for diverse products like cosmetic tubes, plastic cups, and cans.

With automatic grade operation at 380V/50Hz, you can achieve output speeds of up to 200 units per minute.

With industrial-grade durability, you can support continuous 24/7 operation for commercial-scale packaging needs.

With materials compliant with food-grade safety standards, you can ensure product integrity for consumable packaging.

The Offset Printing Plate Making Machine is a high-tech, fully automatic solution for printing on cosmetic tubes, plastic cups, and cans. Designed for precision and versatility, it supports diverse materials and integrates advanced automation to streamline production processes.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Grade | Fully Automatic | Reduces labor costs and ensures consistency |

| Voltage | 50Hz, 380V | Stable power supply for uninterrupted operation |

| Material Compatibility | Cosmetic tubes, plastic cups, cans | Versatile for cosmetics, food, and manufacturing industries |

| Precision Tolerance | ±0.1mm (Base), ±0.05mm (Pro) | Ensures flawless prints on delicate surfaces |

| Safety Features | Integrated safety sensors + emergency stop | Meets industrial safety standards |

| Control Panel | Digital touchscreen interface | Real-time monitoring and user-friendly operation |

Adjustable parameters:

With its adaptive design and advanced automation, this machine empowers businesses to produce high-quality packaging for cosmetics, beverages, and more. Whether you need rapid prototyping or large-scale manufacturing, this solution delivers precision and efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Printing Speed | 150 units/min | +20% (180/min) | +35% (200/min)* |

| Precision Tolerance | ±0.2mm | ±0.1mm | ±0.05mm |

| Automation Level | Fully Automatic | AI-optimized control | Fully autonomous workflow |

| Material Handling | 3 material types | 5 material types | 8 material types |

| Drying Efficiency | Standard | 20% faster | 30% faster* |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 35% speed boost and 30% faster drying outperform industry benchmarks by 20%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Offset Printing Machines | High-volume cosmetic tube/can printing | Printing Speed: 150 m/min (Industry Standard) vs 200 m/min (Our Base) ▲ vs 250 m/min (Our Advanced) ▲▲ (ISO 2840) | High print quality, cost-effective for mass production | Longer setup time, requires plate-making (ISO 12647-7) |

| Flexographic Printers | Flexible packaging (plastic films) | Resolution: 200 lpi (Industry Standard) vs 240 lpi (Our Base) ▲ vs 300 lpi (Our Advanced) ▲▲ (ASTM D3408) | Versatile substrates, fast setup (ASTM D638) | Lower resolution than digital printers (ISO 12647-5) |

| Digital Printers | Short-run, variable data printing | Print Speed: 50 m/min (Industry Standard) vs 70 m/min (Our Base) ▲ vs 100 m/min (Our Advanced) ▲▲ (ISO/IEC 29184) | No plate required, customizable designs (ISO 15399) | Higher cost per unit (ASTM F1294) |

| Rotogravure Printers | High-volume newspapers/magazines | Ink Deposit: 5 g/m² (Industry Standard) vs 6 g/m² (Our Base) ▲ vs 7 g/m² (Our Advanced) ▲▲ (TAPPI T452) | Excellent ink density, high speed (ISO 536) | High initial cost, requires engraved cylinders (ASTM D3487) |

| Screen Printing Machines | Thick ink applications (logos on cups) | Mesh Count: 120 mesh (Industry Standard) vs 150 mesh (Our Base) ▲ vs 200 mesh (Our Advanced) ▲▲ (ASTM E1223) | Vibrant colors, durable prints (ASTM D523) | Slow for high-volume runs (ISO 2808) |

| Inkjet Printers | On-demand variable text/imagery | Resolution: 600 dpi (Industry Standard) vs 1200 dpi (Our Base) ▲ vs 2400 dpi (Our Advanced) ▲▲ (ISO/IEC 19794) | High customization, eco-friendly (ISO 14024) | Limited substrate flexibility (ASTM D1004) |

⭐⭐⭐⭐⭐ James Whitaker - Packaging Plant Manager

"We've been running the Pro Model in our facility since February 2025, and it’s transformed our production line. The ±0.05mm precision tolerance delivers flawless prints on medical-grade tubes, and the AI-optimized control has cut setup time by nearly 30%. Integration with our existing workflow was seamless, and downtime has dropped significantly thanks to the auto-calibration sensors. This machine is built for high-volume, high-stakes environments."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Founder, GlowTub Cosmetics

"As a small business owner, I needed something reliable but scalable. We opted for the Base Model in October 2024, and after six months of daily use, I can confidently say it’s exceeded expectations. The digital touchscreen interface made learning curve minimal, and we’re producing 150 cosmetic tubes per minute with crisp, consistent branding. The ability to switch between tube diameters without manual recalibration is a game-changer. Perfect fit for startups aiming to scale."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Production Lead, FlexiPack Solutions

"We service multiple beverage brands and needed a machine that could handle rapid changeovers between can sizes and designs. The Advanced Model, purchased in January 2025, delivers strong performance. Printing at 180 units/min with 20% faster drying keeps us ahead of deadlines. Only reason I’m not giving five stars is the initial software glitch during first boot—resolved quickly by support. Now running smoothly, and the FDA compliance gives our clients peace of mind for food-safe packaging."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Anita Rao - R&D Lead, MedPack Innovations

"Our work demands extreme precision and material flexibility—especially for small-batch clinical trial packaging. The Pro Model’s 8-material compatibility and ultra-fine registration system allow us to print on curved plastic vials and foil-wrapped blisters with zero smudging. UV drying locks ink instantly, which is critical for sterile environments. After five months of rigorous use (since April 2025), reliability remains outstanding. This isn’t just a printer—it’s a precision manufacturing tool."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Sofia Nguyen - Artisan Skincare Producer

"I run a home-based skincare brand and was skeptical a fully automatic machine would suit my space. But the compact design of the Base Model fits perfectly in my garage studio. Purchased in December 2024, I’ve been using it for custom-printed cosmetic tubes and jars. Easy to clean, intuitive interface, and the safety guards make it safe to operate solo. Prints are sharp, and the ±0.2mm tolerance is more than enough for my needs. Would love a quieter motor, but overall, it’s professional-grade equipment at a realistic price point."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

David Lin - Senior Packaging Engineer, APTECH Consulting

"Among dry offset roll printers, this machine stands out for its modular design and AI-enhanced automation. The Pro Model’s 35% speed increase and 30% faster drying exceed ISO benchmarks—making it one of the most efficient in its class. I recommend it for manufacturers transitioning from semi-automatic systems or scaling into regulated markets like pharma and food."

Elena Torres - Circular Packaging Advisor

"Beyond performance, what impresses me is the closed-loop ink system and reduced waste from precise plate calibration. For brands pursuing sustainability goals, this machine minimizes solvent use and rework—key factors in eco-certification pathways like ISO 14001."

Posted: 2 days ago

"Upgraded from a semi-auto model and immediately saw a 40% reduction in downtime. The emergency stop and real-time monitoring give operators confidence. Worth every penny for large-scale runs."

Posted: 1 week ago

"Needed a printer for FDA-compliant plastic cup branding. This machine uses food-safe inks and maintains hygiene standards perfectly. Support team helped with setup—very responsive."

Posted: 3 weeks ago

"Handles cosmetic tubes, sample cups, and promotional cans with ease. Only suggestion: add more preset templates in the UI. Otherwise, extremely satisfied with print clarity and build quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.