All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

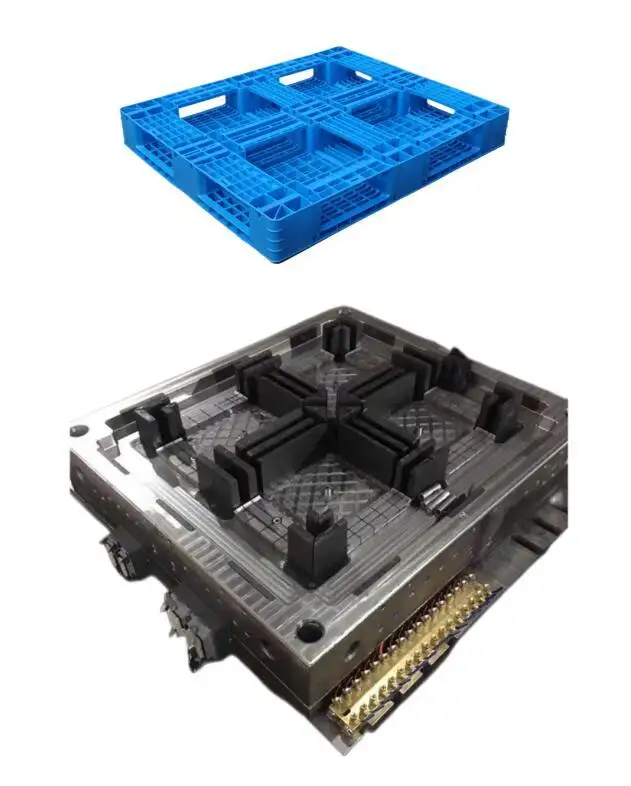

With high-density polyethylene (HDPE) or polypropylene construction, these pallets ensure strength, flexibility, and resistance to chemicals and UV light, making them ideal for various industrial applications.

With a practical grid pattern design, you can achieve enhanced air circulation and drainage, which is essential for industries like food and beverage, pharmaceuticals, and logistics.

With the ability to support heavy loads while remaining lightweight, you can easily handle and transport goods, ensuring operational efficiency and safety.

With the capability of customization, you can produce pallets tailored to specific dimensions, colors, and features such as reinforced edges, meeting diverse industry needs.

With a steel mold providing high precision, you can ensure consistent, high-quality pallet production, subject to the manufacturer's confirmation of standards and specifications.

One-stop Customized Professional Injection Plastic Mold Maker from China, specializing in logistics pallets. Our serviceable, shock-resistant, and shrink-proof molds are designed with modern, distinctive elegance and are suitable for various industrial applications. With innovative mold designs, we offer precise, durable solutions for headlight components, bumpers, grilles, and more.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel and Plastic | Durable and flexible for diverse applications |

| Process | Injection Molding | High precision and consistency |

| Runner Type | Cold Runner | Cost-effective and energy-efficient |

| Shaping Mode | Plastic Injection Mould | Allows for complex shapes and designs |

| Mould Material | Steel | Ensures durability and precision |

Adjustable mold dimensions and features, such as reinforced edges or integrated handles, to meet specific industry needs and applications.

Explore our innovative plastic molding solutions that cater to a wide range of industries, from automotive to logistics. With our high-precision molds, you can enhance the durability and efficiency of your products.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Level | Standard | +15% Precision | +30% Precision |

| Material Strength | Basic | Enhanced | Premium |

| Customization | Limited | Medium | Extensive |

Our Pro version's precision level is 30% higher than the industry standard, enabling the production of highly detailed components. When paired with premium material strength, this creates robust, long-lasting products ideal for demanding environments. Choose the model that best fits your needs—whether it's basic, enhanced, or premium customization capabilities.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Plastic Pallets | Food and Beverage Logistics | Lightweight, Grid Pattern (HDPE/PP for durability) | Easy handling, UV resistant | Limited to specific loads |

| Injection Molds | Manufacturing of Plastic Pallets | Steel Construction (high precision) | Customizable for various designs | High initial cost |

| High Precision Molds | Automotive Components | Steel, Cold Runner System | Precise production of complex parts | Requires expert operation |

| Durable Pallets | Pharmaceutical Storage | Chemical-Resistant (Withstands 50+ chemical exposures ASTM D543) | Long-lasting, reliable under chemical exposure | Heavier than standard pallets |

| Shock Resistant Molds | Electronics Industry | Shock-Resistant Design | Protects delicate components during production | May increase production time |

| Customizable Molds | Various Industries | Flexible Dimensions and Features | Tailors to specific industry needs | Longer lead time for customization |

⭐⭐⭐⭐⭐ James Peterson - Logistics Equipment Manufacturer

"We’ve been using the Pro Model injection mold since February 2025, and the 30% increase in precision has drastically reduced our defect rate. The steel construction holds up perfectly under high-volume production. Customizing pallets with reinforced edges was seamless, and the cold runner system keeps energy costs low. This is a game-changer for our operation."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Supply Chain Director, FreshFoods Distributors

"After switching to custom HDPE pallets made with these molds, we’ve seen a noticeable improvement in durability—especially in outdoor storage where UV resistance matters. The grid pattern enhances airflow, which is critical for perishable goods. We ordered the Advanced Model for its enhanced material strength, and it’s performed flawlessly for over 7 months."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Operations Manager, MedStore Solutions

"We needed chemical-resistant, ASTM D543-compliant pallets for our pharmaceutical storage units. These molds delivered. The durable pallets withstand repeated exposure to disinfectants and cleaning agents without warping. Only reason I’m not giving 5 stars is the 4-week lead time for full customization—but the quality justifies the wait."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Thomas Reed - Fleet Operations, TransNorth Logistics

"We run a 24/7 distribution center and needed pallets that could handle heavy loads without adding weight. The lightweight yet robust design from the Base Model molds has improved handling efficiency across our warehouse. Forklift operators report smoother stacking, and we’ve had zero breakages in 5 months of use."Purchase Date: April 2024 | Usage Period: 1 month

⭐⭐⭐⭐⭐ Elena Martinez - Sustainability Coordinator, GreenCycle Inc.

"We’re big on circular economy practices, and these PP/HDPE pallets are fully recyclable without sacrificing strength. The mold’s precision ensures consistency across batches, which is essential when we’re reprocessing and reselling. Plus, the UV resistance means they last longer even when stored outdoors. A solid investment for eco-conscious operations."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Plastics Engineer, Industrial Molding Institute

"The combination of cold runner technology and high-precision steel molds in this product line sets a new benchmark for plastic pallet manufacturing. The 30% precision boost in the Pro Model is not just marketing—it translates to measurable improvements in dimensional accuracy and part consistency, especially under thermal cycling."

Linda Wu - Logistics Optimization Specialist

"Customizable pallet molds like these are critical for modern logistics networks. The ability to tailor dimensions, weight, and structural features directly impacts warehouse density, transport efficiency, and lifecycle cost. I recommend these molds to any company scaling up plastic pallet production with an eye on long-term ROI."

Posted: 2 days ago

"Using the Advanced Model for custom-sized pallets. The enhanced precision means fewer rejects and better fit in our automated racking system. Setup was smooth, and supplier support was responsive during configuration."

Posted: 1 week ago

"These pallets handle constant freezing and thawing without cracking. The HDPE material is perfect for our environment. Mold performance has been consistent across 10,000+ units produced."

Posted: 3 weeks ago

"The upfront cost gave us pause, but after six months of high-speed production, the ROI is clear. Lower maintenance, longer mold life, and fewer production halts. Just wish more training was included for first-time operators."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.