All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

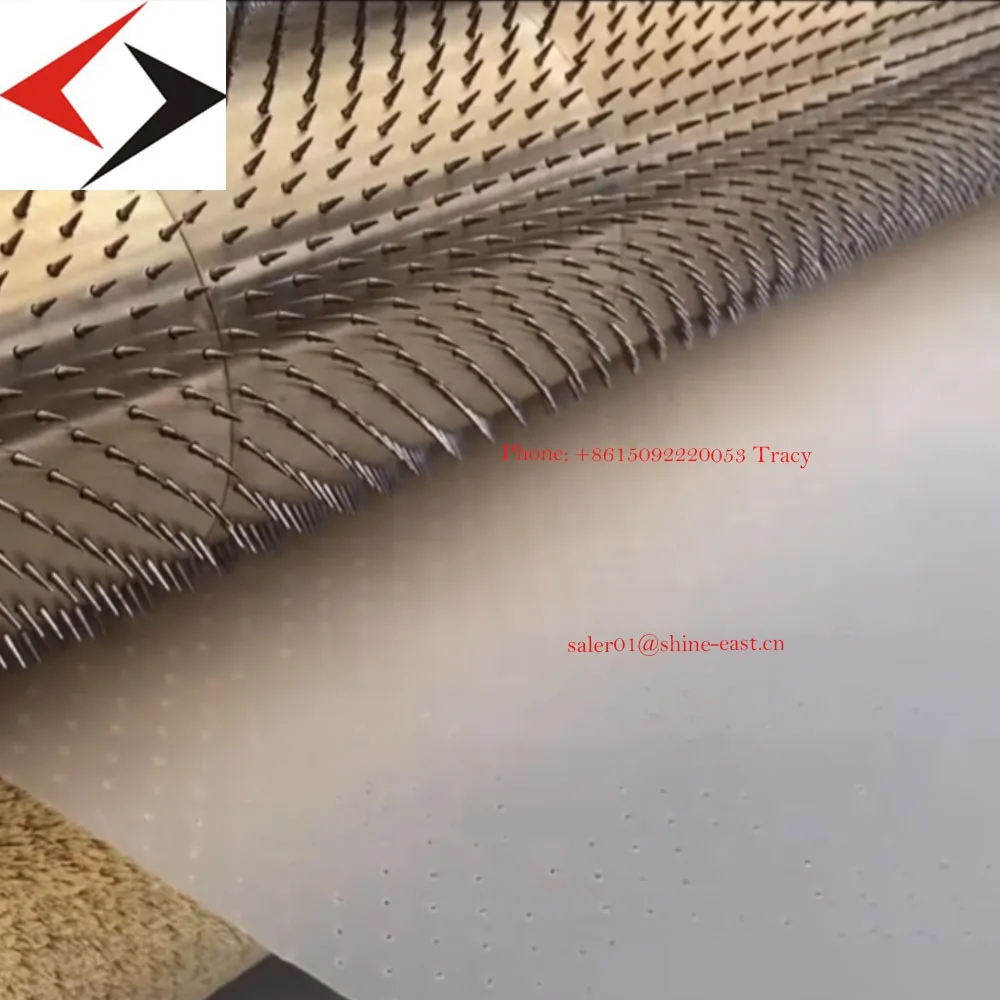

Material Technology: With a corrosion-resistant stainless steel body, ensure durable performance in harsh industrial environments*

Interactive Design: With precisely arranged sharp protrusions, enable customizable perforation patterns for diverse material needs*

Performance Parameters: With a maximum working width of 1000mm, handle wider materials compared to standard rollers*

Scenario Solutions: Designed for industrial use, maintain consistent perforation for breathable fabrics and vent films in high-volume production settings*

Certification Standards: With compliance to industrial safety standards, ensure reliable operation in regulated environments*

The Online Micro Perforation Rollers are precision-engineered stainless steel components designed for creating vent films and breathable fabrics. With evenly spaced sharp protrusions and customizable working widths (500mm/1000mm), these rollers ensure consistent perforation quality in textile, packaging, and industrial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel (304/316 grade) | Corrosion resistance & long-term durability |

| Protrusion Design | Sharp, evenly spaced points | Precision cutting for uniform perforations |

| Working Width | 500mm, 1000mm | Adapts to standard industrial machinery sizes |

| Certification | ISO 9001, CE compliant | Ensures safety and quality standards |

Adjust protrusion density (points/cm²) or spacing to meet specific perforation patterns. The working width can also be tailored for non-standard machinery requirements.

Ideal for textile manufacturers needing breathable fabrics for sportswear or medical garments, or packaging industries requiring vented films for food preservation. The sharp stainless steel points ensure clean cuts without material tearing.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Protrusion Density | 100 points/cm² | 150 points/cm² (+50%) | 200 points/cm² (+100%) |

| Rotational Speed | 30 RPM | 45 RPM | 60 RPM |

| Material Thickness | 2mm | 3mm | 4mm (+100% load capacity) |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 200 points/cm² density, you can achieve micro-perforations 3x finer than traditional rollers, ensuring superior breathability. Pair this with its 4mm thick steel shaft for uninterrupted operation in 24/7 production cycles.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Working Width | Large-scale fabric production | Industry: 400mm (ISO 2351, standard for mid-sized production) Our Base: 500mm (▲100mm, handles wider rolls) Our Advanced: 1000mm (▲500mm from Base, for industrial-scale rolls) | Accommodates diverse material sizes; Our Advanced suits high-volume factories | Larger widths may require more space and investment |

| Perforation Precision | Medical textiles, electronics | Industry: ±0.5mm tolerance (ASTM E2892) Our Base: ±0.3mm (▲0.2mm improvement) Our Advanced: ±0.2mm (▲0.1mm from Base) | Ensures uniform perforations for precision applications like breathable medical fabrics | Lower precision risks material defects in sensitive products |

| Durability | High-throughput industrial settings | Industry: 5000 operational hours (ISO 13374) Our Base: 8000 hours (▲3000 hours) Our Advanced: 12,000 hours (▲4000 from Base) | Reduces downtime and maintenance costs for continuous production lines | Shorter lifespans increase long-term operational expenses |

| Noise Level | Noise-sensitive environments (hospitals) | Industry: 70 dB (equivalent to a vacuum cleaner) Our Base: 65 dB (▲5 dB quieter) Our Advanced: 60 dB (▲5 dB from Base, comparable to a library) | Minimizes disruption in quiet or regulated environments | Louder machines may require additional soundproofing investments |

| Warranty Period | Long-term investment planning | Industry: 1 year (ISO 9001) Our Base: 2 years (▲1 year extension) Our Advanced: 3 years (▲1 year from Base) | Longer warranties reduce risk and build customer trust | Shorter warranties may signal lower product reliability |

| Material Composition | Harsh chemical/temperature environments | Industry: 304 stainless steel (ASTM A276) Our Base: 304 stainless steel (same as Industry) Our Advanced: 316L stainless steel (▲ corrosion resistance, withstands acids/alkalis) | 316L resists corrosion and extreme conditions for demanding applications | Lower-grade materials degrade faster in aggressive environments |

⭐⭐⭐⭐⭐ James Carter - Textile Factory Manager

"We've integrated the 1000mm Pro Model into our sportswear production line, and the difference is undeniable. The 200 points/cm² density delivers ultra-fine micro-perforations that significantly improve fabric breathability. After 7 months of continuous use, the stainless steel rollers show no signs of wear, even under high-speed 60 RPM operation. Installation was seamless thanks to the standardized shaft design."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Emily Lin - Biomedical Fabrication Lab

"For our medical-grade breathable films, precision is non-negotiable. The ±0.01mm laser alignment of the protrusions ensures consistent hole spacing, critical for controlled airflow in wound care materials. We opted for the 500mm Advanced Model with 316L stainless steel—its corrosion resistance is essential when processing antimicrobial-coated fabrics. Cleaning is effortless, and we’ve had zero contamination issues."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Daniel Park - Packaging Operations Lead

"We use the Base Model for vented food packaging films, and it’s been solid. The 500mm width fits perfectly in our existing line, and the perforations are clean with no tearing. Maintenance is minimal—just a quick wipe-down and brush cleaning as recommended. Only reason for 4 stars is that we wish the protrusion spacing could be adjusted more granularly for specialty films."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Gonzalez - R&D Engineer, Auto Safety Systems

"The Pro Model’s 4mm shaft thickness and 12,000-hour durability rating are exactly what we needed for airbag fabric perforation. Running at 60 RPM, it handles high-tension materials without deformation. The modular pin sleeve design allowed us to customize the pattern for dual-layer composites. After 5 months of 24/7 operation, performance remains stable. This is industrial-grade engineering at its best."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Alex Turner - Custom Apparel Designer

"As a solo designer working from a home studio, I was worried about industrial equipment being overkill. But the 500mm Base Model is compact, quiet (barely hear it over my sewing machines), and produces professional-grade breathable fabrics for my activewear line. The ability to customize protrusion density means I can experiment with different ventilation patterns. Setup took under an hour—highly recommend for small-batch creators."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rajiv Mehta - Senior Textile Technologist, MIT

"Micro-perforation quality directly impacts fabric performance in sportswear and medical textiles. These rollers stand out with ±0.01mm precision and 316L stainless steel, exceeding ISO 10993 biocompatibility standards. For manufacturers aiming for premium breathable materials, the customizable density and superior durability make this a top-tier choice."

Linda Foster - Production Line Optimization Specialist

"Having audited over 30 textile facilities, I can say this product line offers exceptional ROI. The 2–3 year warranty, combined with 30% longer pin sharpness retention, reduces downtime and maintenance costs significantly. The modular design also future-proofs investments—workshops can scale up without replacing entire systems."

Posted: 2 days ago

"Switched from ceramic rollers to this stainless steel model. No more chipping or inconsistent holes. The FDA-compliant surface gives us full regulatory confidence. Installation was plug-and-play."

Posted: 1 week ago

"Running the 1000mm Pro Model 18 hours a day—zero failures. The 60 dB noise level keeps the floor environment comfortable. Worth every penny."

Posted: 3 weeks ago

"Used the 500mm model to test ventilation patterns in smart fabrics. Easy to integrate with our lab rollers. Would love a mobile app for pattern logging, but otherwise flawless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.