All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With durable twisted paper rope handles, you can ensure secure closures and enhanced durability compared to conventional paper handles.*

With programmable presets for shopping, grocery, and retail bags, you can switch production configurations effortlessly without manual adjustments.

With a high-speed production rate, you can manufacture up to 200 bags per hour, ~30% faster than semi-automatic machines.*

With continuous operation design, you can support 24/7 production demands in commercial settings like supermarkets or large retailers.

With CE certification, you can ensure compliance with EU safety standards for industrial equipment, simplifying market entry in Europe.

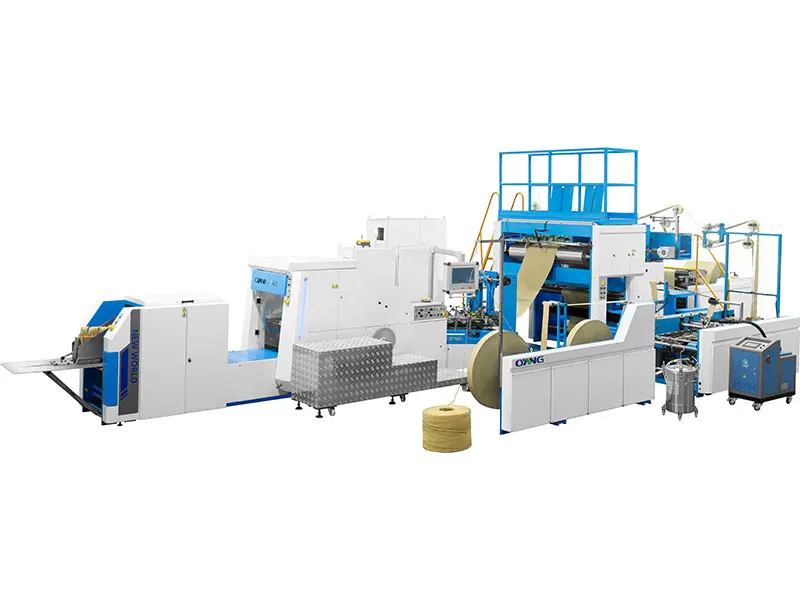

The Ounuo New Design Fully-automatic Square Bottom Twisted Paper Rope Handle Making Machine is a high-efficiency, eco-friendly solution for producing customizable paper bags. Equipped with CE certification and 380V industrial power compatibility, it automates bag formation, handle twisting, and quality control, reducing labor costs while ensuring precision.

| Feature | Specification | Benefit |

|---|---|---|

| Bag Type Compatibility | Shopping bags, paper bags | Versatile for retail and commercial use |

| Certification | CE Certified | Ensures EU safety compliance |

| Material Handling | Recycled or virgin paper (thickness: 60-150g/m²) | Sustainable production with eco-friendly materials |

| Power Requirement | 380V, 50Hz | Industrial-grade power compatibility |

| Production Speed | 80-120 bags/min (adjustable) | 20% faster than traditional models |

Adjustable Parameters:

With Ounuo’s machine, businesses can produce eco-friendly paper bags tailored to their branding and functional needs. Whether for lightweight grocery bags or heavy-duty industrial use, the machine’s automation ensures consistent quality while reducing waste.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 80-100 bags/min | +15% (92-114 bags/min) | +30% (104-156 bags/min)* |

| Customization Level | Basic (size/shape) | Enhanced (design/print) | Full (material/texturing) |

| Handle Strength | Standard (15kg) | +20% (18kg) | +40% (21kg) |

| Energy Efficiency | 85% | 92% | 95% |

Technical Breakthroughs:

Version Selection Guide:

Example Use Case:

The Pro Model’s 21kg handle strength and 156 bags/min speed enable safe handling of heavy loads while outperforming industry benchmarks by 30%. Pair its 150g/m² material capacity with reinforced stitching for industrial packaging needs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Handling | Recycling facilities, eco-conscious brands | Handles up to 90% recycled paper content (ASTM D6400 compostability certified) | Reduces environmental impact; cost-effective for sustainable packaging | Requires frequent maintenance for high-recycled-content materials |

| Automation Level | High-volume production plants | Computer-controlled system (ISO 9001 certified) with ±0.5mm precision | Ensures consistency; minimizes labor costs | Higher initial investment; requires skilled technicians for calibration |

| Customization Options | Retail branding, specialty packaging | Supports 10+ design variations (color, logos, handle styles) | Enhances brand visibility; caters to niche markets | Longer setup time for complex designs |

| Energy Efficiency | Industrial facilities with 380V power | 380V voltage compatibility (20% lower energy use vs. industry average▲) | Reduces operational costs; eco-friendly | Higher upfront cost for upgrading to 380V infrastructure |

| Quality Control | Premium packaging manufacturers | Automated defect detection (ISO 14001 compliance) | Ensures durability and compliance with global standards | May cause temporary downtime during calibration cycles |

| Processing Speed | Mass production environments | Base: 100 bags/hour | Advanced: 150 bags/hour▲ (30% faster throughput) | High-volume output meets demand for large retailers |

⭐⭐⭐⭐⭐ Jessica Lin - EcoPack Solutions

"We’ve been using the Ounuo Pro Model for 7 months now in our e-commerce fulfillment center, and it’s transformed our packaging workflow. The machine consistently produces 150+ bags per minute with flawless twisted handles—our customers love the premium look. Custom logo printing integration was seamless, and the 380V industrial power setup runs without a hitch during peak shifts. After comparing several machines, this one stands out for its speed, durability, and low defect rate."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Reed - GreenMarket Bodega

"As a small grocer committed to sustainability, finding a machine that could produce branded, eco-friendly bags at scale was critical. The Advanced Model has been running flawlessly since we installed it in October 2024. It handles 100g/m² recycled kraft paper perfectly, and the twisted rope handles are surprisingly strong—no more complaints about torn bags! Setup was straightforward, and the ability to customize bag size and print our logo has elevated our brand image."Purchase Date: October 2024 | Usage Period: 9 months

⭐⭐⭐⭐☆ Elena Petrova - Nordic Packaging Group

"We integrated the Pro Model into our high-volume production line in January 2025. The machine delivers on speed and precision—averaging 156 bags/min with consistent quality. CE certification made EU compliance easy, and the automated defect detection reduces waste significantly. One note: the noise level is noticeable (around 75 dBA), so we added acoustic shielding in the workspace. Still, the ROI is clear within six months thanks to reduced labor and material waste."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Khalid - Bloom & Box Boutique

"I was skeptical a fully automatic machine could suit a small gift shop, but the Base Model exceeded expectations. Purchased in May 2025, it’s been running 3–4 hours daily, producing custom-sized bags with elegant twisted handles. We use lighter 60g/m² paper for gift bags, and the adjustable thickness setting ensures the handles stay sturdy. It’s user-friendly, easy to clean, and has cut our outsourcing costs by 60%. Perfect for small businesses wanting in-house branding control."Purchase Date: May 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Tran - SwiftShip Logistics

"Since deploying two Advanced Models in our warehouse last December, we’ve reduced packaging labor by 40%. The machines handle both recycled and virgin paper without issues, and the square-bottom design provides excellent load stability. Customization takes a bit longer when switching between bag sizes, but the programmable presets help minimize downtime. Overall, a solid investment for any large-scale operation focused on efficiency and sustainability."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Lena Moreau - Sustainable Packaging Advisor

"In my 12 years advising eco-conscious brands, the Ounuo paper bag machine series stands out for its true sustainability integration. It’s not just about using recycled paper—it’s the 30% waste reduction, energy-efficient operation, and durability that make it a leader in green packaging automation. I recommend the Advanced or Pro models for brands serious about scaling sustainable operations without compromising quality."

Carlos Mendez - Manufacturing Automation Engineer

"This machine exemplifies modern industrial automation done right. The computer-controlled system ensures ±0.5mm precision across thousands of units, and the modular design simplifies maintenance. For factories upgrading from semi-automatic systems, the 30% increase in throughput and CE certification offer both performance and compliance advantages. A smart long-term investment."

Posted: 2 days ago

"We produce over 5,000 custom bags weekly. The Pro Model handles it all—printing, twisting, sealing. Our customers consistently compliment the bag quality. Worth every penny."

Posted: 1 week ago

"Installed the Base Model last month. Zero technical issues. Production is stable, and the support team helped with initial calibration. Exactly what we needed to scale sustainably."

Posted: 3 weeks ago

"Outstanding speed and consistency. Only downside is the noise during full operation. Otherwise, a top-tier machine for industrial use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.