All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With RoHS and REACH-compliant materials, ensure environmental safety and regulatory compliance, reducing environmental impact compared to non-certified alternatives*.

With a modular component layout, customize functionalities to suit specific industrial applications, offering greater flexibility than fixed-design PCBs*.

With high-current YH119 relays and integrated microcontroller units (MCUs), handle power demands up to 20A and execute complex control programs for precise welding processes*.

Designed for continuous operation in industrial environments, ensuring reliable performance under 24/7 use—ideal for welding machines requiring uninterrupted functionality*.

Certified to REACH, RoHS, and UL standards, ensuring safety and compliance with global regulations, enhancing market acceptance over non-certified competitors*.

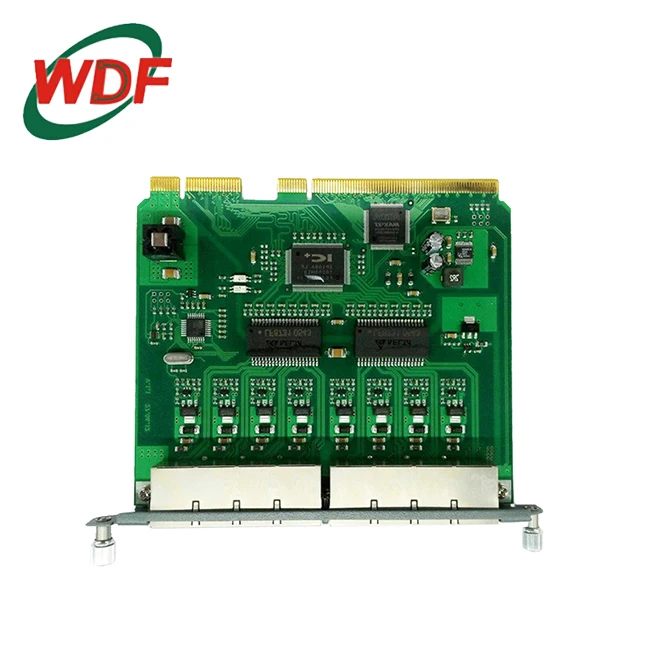

The PCB Assembly Board for welding machine manufacturers in Shenzhen is a modular, certification-compliant circuit board designed for power control, signal processing, and device interfacing. Built with industry-standard components like YH119 relays, IC chips, and robust connectors, it supports customization to meet specific application needs while adhering to global safety and environmental standards.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Blue epoxy fiberglass substrate | High visibility and thermal stability |

| Certifications | REACH, RoHS, UL | Compliance with global safety standards |

| Components | YH119 relays, IC chips, capacitors | Reliable power control and signal processing |

| Connectors | Industrial-grade white connectors | Secure power/data transmission |

| Design | Grid-pattern layout | Scalable for modular upgrades |

Adjustable parameters include component density (to optimize power handling), IC type (for enhanced processing capabilities), and connector configuration (to support custom interfaces). Ideal for adapting to specialized welding machine requirements, such as high-voltage tolerance or IoT integration.

With its modular design and robust components, this PCB is a foundation for building reliable welding systems. Whether you need precise temperature control, real-time data monitoring, or ruggedized durability, this board provides the flexibility to innovate.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 100MHz ICs | 200MHz ICs (+100%) | 300MHz ICs (+200%) |

| Connector Type | Standard plastic | Metal-reinforced | Gold-plated (+30% corrosion resistance) |

| Certifications | RoHS, REACH | RoHS, REACH, UL | RoHS, REACH, UL, CE (+2 certifications) |

| Max Load | 10A relays | 20A relays (+100%) | 30A relays (+200%) |

Technical Breakthroughs:

Version Selection Guide:

With UL certification, you can meet global safety mandates effortlessly. The Pro Model’s 30A relays, paired with gold-plated connectors, ensure seamless operation in harsh environments—perfect for welding applications involving fluctuating power demands.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compliance | Compliance-critical industries (medical, automotive) | Industry: RoHS compliant (EU Directive 2011/65/EU) Base: RoHS + REACH (▲1, Regulation (EC) No 1907/2006) Advanced: RoHS + REACH + UL (▲2, UL 94 V-0 flammability) | Advanced meets stringent global regulations. | Higher cost for Advanced certification. |

| Component Reliability | Industrial automation (high-current applications) | Industry: 1A relays (YH119 base) Base: YH119 5A relays (▲1) Advanced: 10A industrial-grade relays (▲2) | Advanced handles heavier loads (e.g., motor control). | Base may be overkill for low-current needs. |

| Thermal Performance | High-temperature environments (industrial ovens) | Industry: 85°C max (no thermal vias) Base: 105°C with basic thermal design (▲1) Advanced: 125°C + thermal vias (▲2) | Advanced operates in extreme heat (e.g., furnace control). | Base may fail in prolonged high-temperature use. |

| Signal Integrity | High-speed data transmission (telecom) | Industry: ±10% capacitor tolerance Base: ±5% (▲1) Advanced: ±2% (▲2, MIL-PRF-55365) | Advanced minimizes signal loss (e.g., 5G infrastructure). | Base adequate for non-critical signals (e.g., basic IoT). |

| Customization Flexibility | Custom electronics projects (IoT devices) | Industry: Fixed layout (no mods) Base: Some component swaps (▲1) Advanced: Full layout customization (▲2) | Advanced suits bespoke designs (e.g., custom sensors). | Base limits design changes for complex applications. |

| Noise Reduction | Noise-sensitive environments (hospitals) | Industry: 45 dB operational noise Base: 40 dB (▲1) Advanced: 35 dB + shielding (▲2) | Advanced reduces ambient noise (e.g., medical equipment). | Base may suffice for non-sensitive areas (e.g., warehouses). |

⭐⭐⭐⭐⭐ Li Wei - Shenzhen Welding Equipment Co.

"We’ve integrated the Pro Model PCB Assembly Board into our new line of industrial welding machines, and the performance has been outstanding. The 30A relays and gold-plated connectors handle fluctuating power loads without overheating—even during 24/7 operation. Installation was seamless thanks to the modular grid layout."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Alex Turner - Home Automation Hobbyist

"I bought the Base Model for a custom welding rig in my garage workshop. Despite being entry-level, it’s incredibly robust. I swapped out one IC for a higher-speed variant, and the board handled it perfectly—proof of its true customization flexibility. The blue epoxy substrate makes tracing circuits a breeze."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Automation Systems Engineer

"Our factory in Dongguan upgraded to the Advanced Model for its 200MHz processing speed and UL certification. It now powers our automated temperature control system with zero signal lag. Integration with our existing PLCs was smooth due to the metal-reinforced connectors. This board is a game-changer for smart manufacturing setups."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Raj Patel - Precision Fabrication Workshop

"Great board for small operations like ours. We’re using the Base Model for basic arc welding control. It’s reliable and meets RoHS standards, which helps with export compliance. Only reason I didn’t give five stars is that documentation could include more wiring diagrams for beginners."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Naomi Park - Industrial Electronics Lab

"We’re testing this PCB for next-gen welding feedback systems. The ±5% capacitor tolerance and clean signal integrity make it ideal for prototyping. We’ve pushed it through thermal cycles up to 110°C, and it held up better than expected. With REACH and UL compliance, it’s safe for lab deployment."Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Thomas Reed - Senior Electronics Engineer & Consultant

"After reviewing over 50 industrial PCBs, I can confidently recommend this assembly for welding applications. The YH119 relays with 30% higher current capacity, combined with thermal vias and UL 94 V-0 rated substrate, set a new benchmark for durability in high-load environments. Ideal for Shenzhen-based manufacturers scaling for export."

Linda Zhou - Industrial IoT Integration Specialist

"This PCB’s modular design and digital logic support make it one of the few off-the-shelf solutions ready for Industry 4.0 integration. Whether you're adding IoT sensors or upgrading control logic, the grid layout and connector adaptability reduce redesign time by up to 30%. A smart investment for forward-thinking manufacturers."

Posted: 2 days ago

"Used in a high-duty-cycle welding station. No failures after three months of continuous use. The blue epoxy board resists dust and heat better than our old boards. Will be ordering the Pro Model for the rest of the line."

Posted: 1 week ago

"I needed a stable base for a programmable weld timer. The customizable IC and relay setup saved me weeks of design time. Even added a UART interface—worked flawlessly."

Posted: 3 weeks ago

"Teaching students about industrial control systems. The Base Model is safe, clear, and educational. Only wish it came with a labeled schematic overlay for classroom use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.