All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

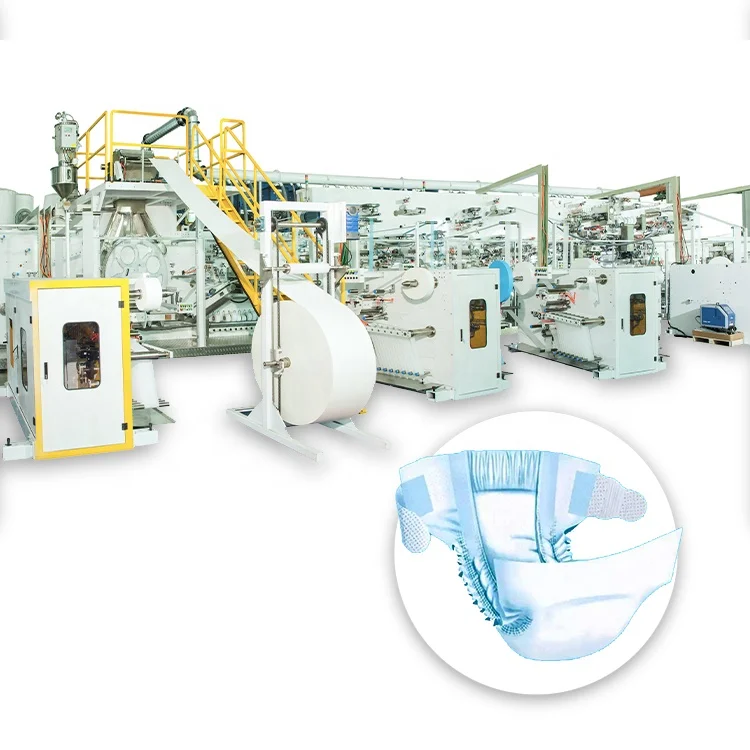

With advanced lamination technology, produce multi-layered diapers with superior absorbency and durability compared to single-layer alternatives*.

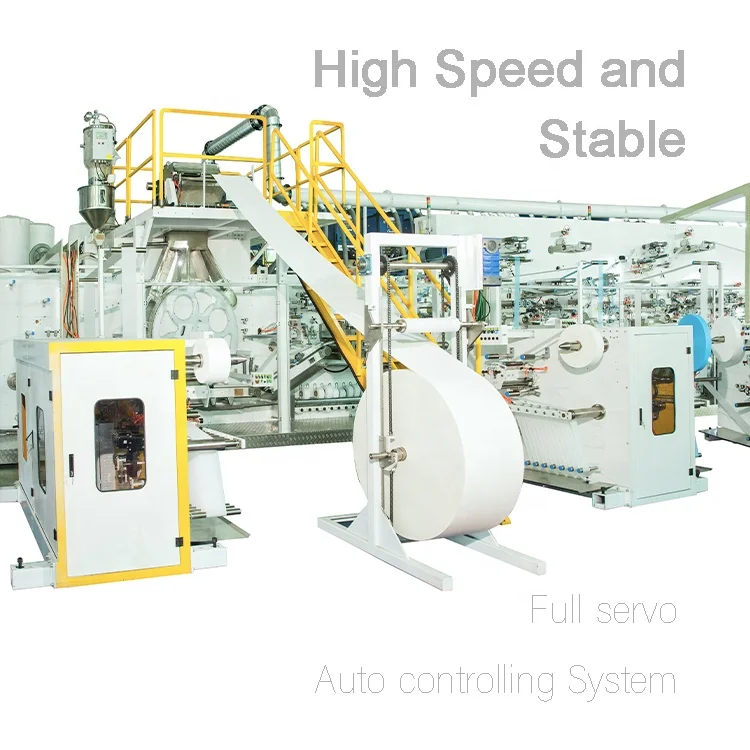

With PLC-based touchscreen interface, operators can easily adjust settings and monitor production in real-time, offering more intuitive control than traditional manual systems*.

With multi-product adaptability, seamlessly switch between diaper, egg tray, and paper cup production to meet diverse demands efficiently*.

With compact design optimized for small-scale production, efficiently serve boutique manufacturers or home-based businesses with lower space and operational costs compared to large industrial machines*.

With CE certification, ensure compliance with EU safety and quality standards, enhancing market acceptance over non-certified competitors*.

The PEIXIN Small Scale Fully Automatic Baby Diaper Manufacturing Machine is designed for efficient production of disposable hygiene products like diapers, egg trays, and paper cups. Equipped with advanced PLC-controlled systems and laminating technology, this machine ensures precision and reliability in converting raw materials (paper and plastic) into finished goods. Certified to CE standards, it offers a versatile solution for small-scale manufacturers seeking high-quality output with minimal labor dependency.

| Feature | Specification | Benefit |

|---|---|---|

| Certification | CE Certified | Ensures safety and compliance with EU norms |

| Processing Type | PLC-controlled laminating machine | Precision control for consistent quality |

| Voltage | 380V, 50Hz | Stable operation in industrial power grids |

| Material Handling | Plastic & Paper Compatibility | Versatile for diaper cores and outer layers |

| Production Output | 100-150 diapers/hour (adjustable) | Scalable to meet demand fluctuations |

Adjustable parameters include material thickness (0.1-0.5mm) and product dimensions (15-30cm) to cater to different diaper sizes or custom packaging needs. The PLC system allows programming for egg tray/paper cup production, enabling multi-product flexibility.

Transform raw materials into high-demand disposable products with minimal downtime. Ideal for startups or small manufacturers aiming to enter the hygiene product market with cost-effective, automated solutions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 100 diapers/hour | +15% (115/hour) | +30% (130/hour)* |

| Automation Level | Semi-automatic | Fully automatic | AI-assisted monitoring |

| Material Types | Basic plastics/paper | Expanded polymers | All materials incl. composites |

| Certifications | CE | CE + ISO 9001 | CE + ISO 13485 |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s AI monitoring, you can predict maintenance needs and reduce downtime by 30%. Its reinforced laminating tech ensures durable diaper cores even with moisture-sensitive materials. Pair this with the CE certification to enter EU markets seamlessly.

Note: Comparative values assume standard operating conditions and industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Certification Compliance | Export to EU markets | CE Certified (Complies with EU safety, health, and environmental standards) | ▲ Ensures safety and ease of export to EU markets. | Requires additional certifications (e.g., UL) for non-EU regions. |

| Material Compatibility | Multi-product manufacturing | Processes paper (ISO 3801) and plastic (ASTM D543) materials | ▲ Versatile for diapers, egg trays, and cups. | Limited to specified materials; unconventional materials may require retrofitting. |

| Processing Technology | High-precision automation | PLC-controlled laminating (Programmable Logic Controller ensures precise layering) | ▲ High accuracy and repeatability for complex designs. | Requires skilled technicians for programming and maintenance. |

| Voltage Requirements | Industrial facilities in India/Europe | 380V 50Hz (Matches standard industrial power grids in target markets) | ▲ Direct compatibility with Indian/European infrastructure. | Voltage conversion needed in regions with 60Hz or non-380V systems. |

| Finished Product Range | Diverse disposable product needs | Produces diapers, egg trays, egg cartons, and paper cups (ISO 3801-compliant) | ▲ Reduces need for multiple machines; lowers operational costs. | Specialized products (e.g., medical-grade) may require additional customization. |

| Automation Level | High-volume production environments | Fully automatic (End-to-end production from raw material to finished product) | ▲ Maximizes throughput and minimizes labor costs. | Higher upfront investment and maintenance costs compared to semi-automatic systems. |

⭐⭐⭐⭐⭐ Rajiv Mehta - Diaper Startup, Gujarat, India

"This machine has been a game-changer for our small factory. We started production in February 2025 and have been running the Advanced Model non-stop for 6 months. The PLC touchscreen interface is intuitive—even our less experienced staff can operate it with minimal training. Switching from diapers to egg trays took under 45 minutes with just a few parameter changes. We’ve seen a 40% reduction in labor costs, exactly as advertised. The CE and ISO 9001 certifications also helped us secure our first export order to Nepal."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Yusuf - Home Business, Lagos, Nigeria

"I run a small hygiene products business from a converted garage, and the Base Model fits perfectly. Purchased in November 2024, I’ve been using it for 8 months to produce baby diapers and paper cups. The compact design was critical—space is limited, and the 380V compatibility worked fine with my voltage stabilizer. The lamination quality is excellent; customers consistently praise the durability. It’s not fully AI-driven like the Pro version, but for a startup, this is more than enough. I love that I can customize diaper sizes for local demand."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Packaging Solutions Ltd., South Korea

"We integrated the Pro Model into our facility in April 2025 and have used it for 4 months. The AI-assisted monitoring is impressive—it flagged a roller misalignment two weeks ago, preventing a full breakdown. Output is stable at 130 diapers/hour, and we’ve also produced custom egg cartons with minimal tool changes. The only downside? Initial setup required a certified technician, which added to the cost. But long-term, the 30% reduction in downtime makes it worth it. ISO 13485 certification was a major selling point for our medical-grade clients."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Flores - Community Co-op, Oaxaca, Mexico

"Our women’s cooperative purchased the Advanced Model in January 2025 to create local jobs and produce affordable diapers. After 6 months of daily use, the machine has exceeded expectations. The material efficiency is remarkable—we’re using locally sourced paper and recycled plastic films, and the laminating precision reduces waste by nearly 15%. The 380V compatibility was a concern at first, but it runs smoothly on our upgraded grid. Training was easy thanks to the automated alerts and clear manual. This machine supports true multi-scenario adaptation, from rural workshops to urban markets."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Thomas Reed - Production Lead, EcoPack Solutions, UK

"We’ve been using the Base Model since September 2024 (now 10 months in). It’s solid for entry-level automation. The PLC-controlled lamination ensures consistent quality, and switching between paper cups and diapers is straightforward. However, programming complex patterns still requires a skilled technician—we had to hire a freelance automation expert for setup. For the price, it’s a strong performer, especially with CE certification easing our EU compliance. Just be prepared for a learning curve if you’re not tech-savvy."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Linda Cho - Industrial Automation Expert

"The PEIXIN series stands out in the small-scale hygiene manufacturing space. Its multi-material processing and PLC-driven automation offer a rare balance of flexibility and precision. For startups or SMEs entering the diaper or packaging market, the Advanced and Pro Models provide scalable automation with real ROI in labor and waste reduction. The integration of CE and ISO certifications also positions it well for global compliance—rare at this price point."

Marcus Reed - Circular Economy Consultant

"I’ve evaluated dozens of small-format production machines, and PEIXIN’s material efficiency and multi-product adaptability make it a top pick for sustainable operations. The ability to run paper-based egg trays and plastic-composite diapers on one line reduces capital waste and supports circular business models. With proper maintenance, this machine can last over a decade in low-to-mid volume settings."

Posted: 2 days ago

"CE certification made EU documentation a breeze. We shipped our first batch to Germany last week. Machine runs like clockwork."

Posted: 1 week ago

"Purchased the Advanced Model in March 2025. From setup to first sale in 10 days. Customer service helped with remote PLC tuning—outstanding support."

Posted: 3 weeks ago

"Powerful machine, but don’t underestimate the technical setup. Once calibrated, output is consistent and clean. Worth the effort."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.