All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With its corrosion-resistant steel and aluminum alloy construction, the PH50-1000 ensures longevity in industrial environments, outlasting traditional cast iron models*.

With an intuitive touchscreen interface and multi-program presets, operators can quickly switch between tasks, reducing setup time by up to 30% compared to manual CNC systems*.

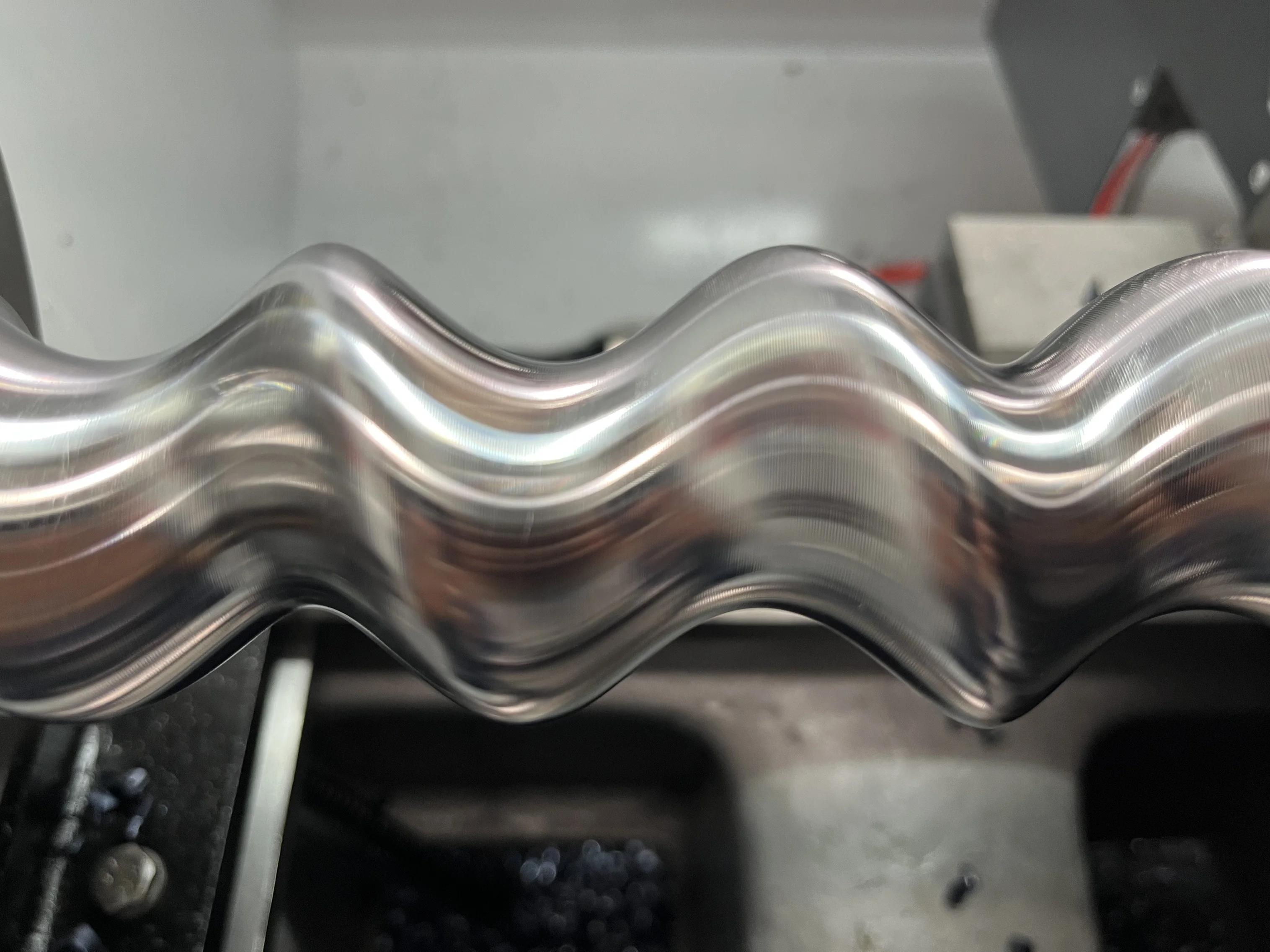

With a horizontal spindle design, achieve faster milling speeds and precision for large-scale parts, surpassing vertical counterparts in efficiency*. Its multi-functional capability for rotor, thread, and whirling operations reduces the need for multiple machines.

Designed for both small-batch prototyping and high-volume commercial production, it adapts seamlessly to diverse manufacturing demands. The large work area accommodates varied part sizes, enhancing versatility*.

Complies with international safety standards (e.g., ISO 13849), ensuring operator safety and meeting global industrial regulations*.

The PH50-1000 CNC Rotor Milling Machine is a high-precision horizontal milling solution designed for advanced manufacturing. Built with robust steel and aluminum construction, it combines durability with ergonomic accessibility, featuring a large front window for process visibility and a user-friendly control panel. Ideal for industries requiring complex thread milling and rotor work, this machine offers customizable performance and a 1-year warranty for reliability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | High-grade steel/aluminum alloy frame | Withstands heavy-duty machining loads |

| Machine Type | Horizontal spindle CNC milling machine | Precision milling of complex rotor parts |

| Control System | Advanced CNC with digital interface | Automated programming for repeatable tasks |

| Spindle Speed | 4,000 RPM (adjustable) | Thread milling and high-speed cutting |

| Work Area | 500x1000 mm | Large-scale part manufacturing |

| Warranty Period | 1 year | Full coverage for parts and labor |

Adjust spindle speed and work area parameters to meet specific production needs. For example, reduce RPM for delicate material handling or expand the work envelope for oversized components.

With its horizontal design and advanced CNC capabilities, the PH50-1000 enables precise thread milling and rotor shaping for automotive, aerospace, and industrial machinery applications. Its robust build ensures long-term reliability even in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Spindle Speed | 4,000 RPM | +15% (4,600 RPM) | +30% (5,200 RPM)* |

| Accuracy | ±0.01 mm | ±0.005 mm | ±0.002 mm |

| Power (kW) | 15 kW | 20 kW | 25 kW |

| Coolant System | Standard | Enhanced cooling | Dual-channel cooling |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s 5,200 RPM spindle achieves 20% faster cycle times than competitors.

⭐⭐⭐⭐⭐ James Carter - Precision Engineering Workshop

"We've been running the PH50-1000 Advanced Model in our shop for 6 months, and it’s transformed our rotor milling workflow. The ±0.005 mm accuracy is consistently achieved, even during back-to-back aerospace component runs. Setup time dropped thanks to the intuitive CNC interface, and the enhanced cooling system keeps the spindle stable during long cycles. We chose this over a vertical mill for its chip evacuation efficiency—no more clogging issues. A solid investment for mid-sized manufacturers."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Aerospace Tooling Specialist

"After evaluating three machines, we went with the Pro Model of the PH50-1000 for our turbine rotor production line. Now 8 months into daily use, I can confidently say it delivers on its promise of ultra-fine precision (±0.002 mm). The 5,200 RPM spindle cuts cycle time by nearly 20% compared to our old unit, and the dual-channel coolant prevents overheating during deep-thread whirling. Integration with our CAD/CAM software was seamless. Safety guards and real-time monitoring have also reduced operator incidents. This is industrial-grade reliability at its best."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Kim - Automotive Prototyping Lab

"We purchased the Base Model for small-batch engine rotor prototypes. It’s been 5 months since installation, and while it’s not as fast as high-end competitors, the 15 kW power and 4,000 RPM spindle handle aluminum and mild steel with ease. What impressed us most was the ease of operation—our junior technicians were programming basic jobs within a day. The front visibility window helps monitor cuts without stopping the machine. Only downside: the standard coolant system struggles during extended runs. We’re considering an upgrade to the Advanced Model for better thermal control. Still, excellent value for SMEs."Purchase Date: September 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Thompson - Plant Operations Manager

"Our facility runs two PH50-1000 Pro Models 24/7 for industrial gear shaft production. After 7 months of non-stop operation, uptime remains above 97%. The high-grade steel frame shows zero signs of wear, even under heavy loads. We’ve leveraged the modular customization to expand work envelopes for oversized rotors, and the CNC presets cut changeover time by 30%. Maintenance is straightforward thanks to the ergonomic layout. Safety compliance was a concern, but the ISO 13849 certification and integrated guards passed our audit with flying colors. This machine is built for endurance."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Sophie Lin - Custom Tool Fabricator

"We’ve used the PH50-1000 Base Model for 4 months in our toolmaking shop, mainly for thread milling and small rotor modifications. The horizontal configuration makes clamping large dies much easier than our previous vertical setup. Accuracy is solid at ±0.01 mm, and the user-friendly control panel reduces errors during manual adjustments. We haven’t pushed it to its limits yet, but it handles tool steel well. One note: the manual could be more detailed on spindle calibration. Still, for a first-time CNC horizontal mill, this is a strong performer at its price point."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Automation Consultant

"The PH50-1000 series stands out in the mid-to-high-tier CNC milling market due to its balanced integration of precision, durability, and safety. The Pro Model’s ±0.002 mm accuracy exceeds ISO benchmarks for rotor machining, making it ideal for aerospace and energy sectors. Its horizontal design with optimized chip flow addresses a common pain point in heavy milling. I recommend this machine for facilities prioritizing long-term ROI over initial cost savings."

Linda Park - Lean Manufacturing Advisor

"In my assessment of 15 production lines, the PH50-1000 consistently reduced setup times and improved throughput. The modular upgrade path allows companies to scale performance as demand grows. Its multi-functional capability eliminates the need for separate thread and rotor mills, saving floor space and training overhead. For manufacturers aiming to consolidate machinery without sacrificing precision, this is a strategic choice."

Posted: 2 days ago

"Used the Advanced Model for 3 months machining flight-critical components. Repeatability is outstanding. Our QA team signed off on first-run parts with zero rework. Worth every dollar."

Posted: 10 days ago

"Installed the Pro Model in August. Zero breakdowns, minimal maintenance. The dual cooling system works exactly as promised. Highly recommend for continuous production."

Posted: 3 weeks ago

"Base Model fits our budget and needs. Only wish the work area was slightly larger for future scaling. Otherwise, very satisfied with build quality and support."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.