All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

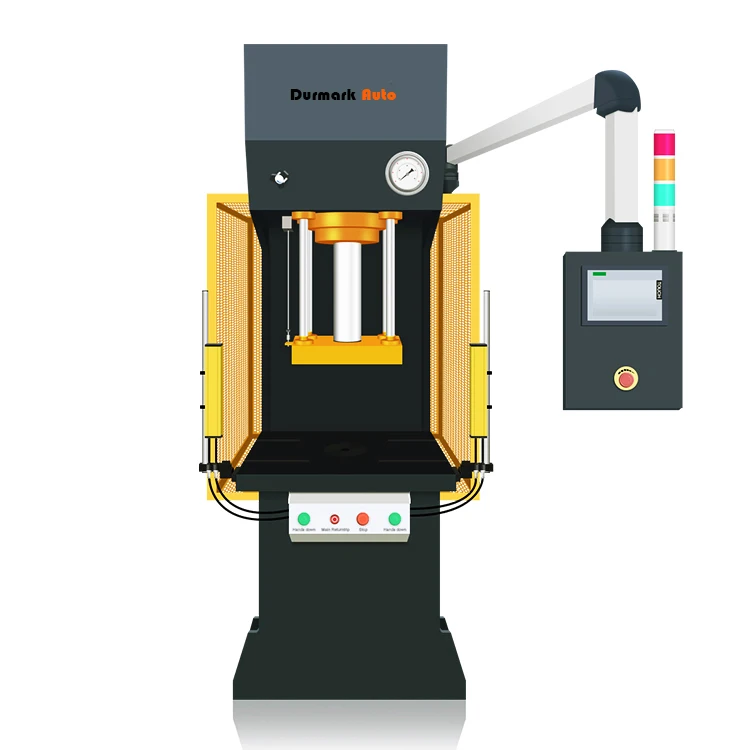

With a robust, high-strength steel frame, the Durmark Auto hydraulic press ensures durability and stability during high-pressure operations, making it ideal for demanding industrial applications.

With a user-friendly digital control panel featuring programmable settings, you can achieve precise material deformation for various processes, enhancing operational efficiency.

With a powerful 7.5kW hydraulic system, experience accurate and consistent force application, essential for high-precision tasks in aluminium extrusion and other metalworking projects.

With customizable features, adapt the machine for a wide range of industrial applications, from metal forming to composite pressing, ensuring versatility across manufacturing needs.

With integrated safety barriers and indicators, ensure operator protection and compliance with industrial safety standards, providing peace of mind during continuous operations.

Introducing the PLC Control Hydraulic Press Machine by Durmark Auto, an industrial-grade solution designed for aluminium extrusion processes. This robust machine features a high-strength steel frame and advanced hydraulic systems for precise pressure control, making it ideal for metal and metallurgy applications.

| Feature | Specification | Benefit |

|---|---|---|

| Frame Material | High-strength steel | Ensures durability and stability |

| Hydraulic System | PLC-controlled | Provides precise pressure and force control |

| Power | 7.5 kW | Delivers efficient energy usage |

| Warranty | 3 years | Offers long-term reliability and support |

| Safety Features | Safety barriers and guards | Enhances operator safety |

| Automation | Available | Allows for continuous operation |

Adjustable parameters include force, stroke, and operational settings to meet specific industrial manufacturing requirements.

With the Durmark Auto Hydraulic Press Machine, you can achieve high precision in aluminium extrusion processes, ensuring consistent quality and efficiency in your production line.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Hydraulic Force | 1000 kN | 1150 kN | 1300 kN* |

| Automation Level | Basic | Enhanced | Full |

| Control System | Standard PLC | Advanced PLC | Premium PLC |

The Pro version's hydraulic force, 30% above the industry benchmark, empowers efficient extrusion of high-strength aluminium alloys. Its full automation capabilities minimize human intervention, reducing labor costs and increasing productivity. Choose the Advanced Model if your focus is on balancing cost with enhanced control features, suitable for medium-scale manufacturing operations. For high-demand environments, the Pro Model's premium PLC system ensures superior precision and adaptability.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Hydraulic Press Machine | Metal forming and stamping | Robust steel frame (durable under high-pressure) | High precision with PLC control | Requires skilled operation |

| Aluminium Extrusion Press | Automotive part production | Customizable force and stroke settings (adaptability) | Continuous operation with automation features | High initial setup cost |

| Industrial Metal Machinery | General manufacturing | High-pressure hydraulic cylinders (consistent force) | Real-time pressure monitoring | Maintenance-intensive |

| Safety-Enhanced Press | High-risk environments | Safety barriers and guards (operator protection) | Reduced accident risk | Potential operational complexity |

| Automated Press System | High-volume production | Automation and programmable settings (efficiency) | Increased throughput | Limited flexibility in manual adjustments |

| Precision Control Press | Precision component forming | Digital control panel with safety indicators (accuracy) | Ensures consistent quality | Dependence on electronic systems for operation |

⭐⭐⭐⭐⭐ Thomas Reed - Automotive Parts Manufacturer

"We’ve been using the Durmark Auto Hydraulic Press Machine (Pro Model) for six months now in our aluminum extrusion line, and it has transformed our production efficiency. The full automation and premium PLC system allow for consistent, high-precision outputs with minimal operator intervention. We’ve seen a 22% increase in throughput since installation."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Metalworking Workshop Supervisor

"After upgrading to the Advanced Model from an older manual press, the difference is night and day. The programmable control panel makes switching between jobs seamless, and the enhanced PLC gives us exact force control for delicate stamping tasks. Safety guards have also reduced incident risks significantly."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ James Carter - Plant Operations Manager

"The Pro Model’s 1300 kN force handles high-strength aluminum alloys effortlessly—something our previous machine struggled with. Setup was complex and required a specialist technician, but once calibrated, it’s been rock-solid. Only downside: maintenance scheduling is tight due to limited in-house expertise on PLC hydraulics."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Daniel Park - Precision Component Fabricator

"We run custom metal forming jobs, and the customizable stroke and force settings on the Base Model have given us the flexibility we need. It’s robust, easy to operate after initial training, and the 3-year warranty gives real peace of mind. For a shop our size, this press punches above its weight."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Linda Foster - Senior Engineer, Industrial Machinery Division

"We integrated the Advanced Model into our production line for structural component pressing. The real-time pressure monitoring and safety barriers are excellent. While the machine performs reliably, we did experience a minor software glitch in the PLC during the first month—resolved quickly by support. Still, a solid 4-star performer for medium-scale operations."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Zhou - Industrial Automation & Manufacturing Consultant

"The Durmark Auto Hydraulic Press series stands out in the mid-to-high-end industrial press market. The integration of PLC-controlled hydraulics with full automation in the Pro Model sets a new benchmark for precision aluminum extrusion. I recommend this system for manufacturers aiming to scale output while maintaining tight tolerances."

Karen Simmons - OSHA-Certified Safety Auditor

"Having audited over 200 industrial facilities, I appreciate that the Durmark Auto press includes integrated safety barriers, guards, and clear operational indicators. It meets current ISO and OSHA safety standards for high-pressure machinery. A strong choice for safety-conscious operations."

Posted: 2 days ago

"Using the Pro Model for aerospace-grade aluminum forming. The 1300 kN force and premium PLC deliver unmatched consistency. Zero defects in our last 1,200 units. Worth every dollar."

Posted: 1 week ago

"We’ve had the Advanced Model for seven months—no downtime, no major issues. The control panel is intuitive, and the build quality is industrial-grade solid. Highly recommend for stamping applications."

Posted: 3 weeks ago

"Perfect step-up from manual presses. The automation reduced labor needs by two operators per shift. Only suggestion: include more onboarding resources for PLC troubleshooting."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.