All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

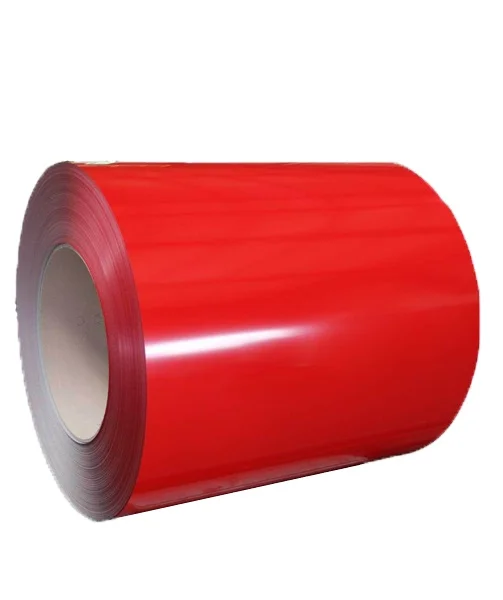

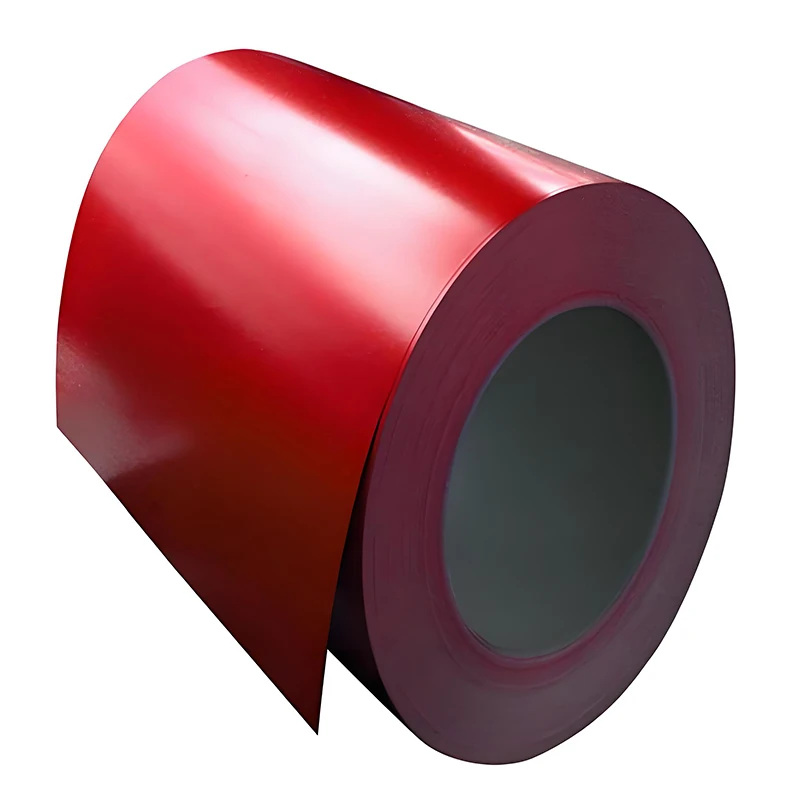

With a corrosion-resistant galvanized steel base and prepainted color coating, ensure long-lasting durability and aesthetic appeal in outdoor environments. The Z41-Z60 zinc coating provides superior protection against rust and environmental exposure compared to uncoated steel.

With precise ±1% tolerance and a width range of 901-1000mm, achieve high accuracy in manufacturing and adaptability to diverse project requirements. The mid-hard steel grade (DX51D/DX52D) balances strength and formability for demanding applications like corrugated sheets.

Designed for applications such as container fabrication, corrugated sheets, and fences, this coil offers versatility for construction, automotive, and industrial projects. Its adaptability outperforms single-use materials in multi-purpose workflows.

Complying with EN standards, guarantee international quality and safety certifications for global applications. This ensures compliance with strict regulations in markets prioritizing eco-friendly and durable materials.

With a roll design optimized for easy handling and storage, streamline logistics and installation processes for large-scale projects. The compact form reduces labor intensity compared to flat sheets.

PPGI/PPGL Prepainted Color Coated Galvanized Steel Sheet Coils are engineered for durability and versatility in construction, manufacturing, and industrial applications. With EN standard compliance and mid-hard steel grades (DX51D/DX52D), these coils deliver corrosion resistance, precise tolerance (±1%), and customizable widths (901-1000mm) for applications like small tools, containers, fences, and corrugated sheets.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel (DX51D/DX52D) | High strength for structural applications |

| Coating | Z41-Z60 (galvanized + color) | Corrosion resistance & aesthetic finish |

| Surface Finish | Smooth, polished | Ideal for reflective or decorative uses |

| Tolerance | ±1% | Precision cutting and fabrication |

| Width Range | 901-1000mm | Flexible for diverse project requirements |

| Certification | EN Standard | Compliance with European quality norms |

Adjustable parameters:

With its mid-hard steel and color-coated surface, this material excels in outdoor and industrial settings. For example, corrugated sheets made from these coils provide both structural integrity and weather resistance for roofing, while containers benefit from their impact-resistant coating.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Coating Thickness | Z41 (minimal corrosion) | Z50 (+20% corrosion resistance) | Z60 (+40% corrosion resistance)* |

| Tensile Strength | DX51D (350MPa) | DX52D (410MPa) | DX52D + Enhanced Alloy (+20% strength) |

| Surface Durability | Standard abrasion | Chip-resistant coating | UV-resistant finish (+50% lifespan outdoors) |

Technical Breakthroughs:

Version Selection Guide:

Example Use Case: With the Pro Model’s UV-resistant finish, you can ensure long-term aesthetic integrity for outdoor signage. Pair its Z60 coating with DX52D strength to withstand salt corrosion near oceans.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Thickness | Corrosion-prone environments | Industry Standard: 27.5 g/m² (EN 10169) Our Base: 41 g/m² ▲ Our Advanced: 60 g/m² ▲▲ | Enhanced corrosion resistance (▲ over industry, ▲▲ over base) (EN 10169 compliant) | Higher coating increases weight/cost (Advanced tier) |

| Material Grade | Structural components | Industry Standard: S250GD (250 MPa) Our Base: DX51D (275 MPa) ▲ Our Advanced: DX52D (345 MPa) ▲▲ | Higher yield strength for load-bearing ▲▲ (EN 10149) | Advanced grades may reduce formability |

| Surface Treatment | Outdoor/Architectural projects | Industry Standard: Basic galvanization Our Base: Color Coated ▲ Our Advanced: Color + Scratch-Resistant Coating ▲▲ | Aesthetic appeal + durability ▲▲ (EN 10169) | Advanced coating adds production cost |

| Dimensional Tolerance | Precision manufacturing | Industry Standard: ±2% Our Base: ±1.5% ▲ Our Advanced: ±1% ▲▲ | Tighter tolerances for precise fits (ISO 9001) ▲▲ | Advanced tolerance requires specialized tooling |

| Application Suitability | Industrial/construction projects | Industry Standard: General use Our Base: Containers/Tools ▲ Our Advanced: Corrugated Sheets/High-Stress Fences ▲▲ | Versatile for diverse applications (EN 10346) ▲▲ | Advanced applications require custom fabrication |

| Hardness | Wear-resistant tools | Industry Standard: Soft-Medium (Rockwell B 55) Our Base: Mid-Hard (B65) ▲ Our Advanced: Hard (B75) ▲▲ | Longer tool life ▲▲ (ASTM E18) | Advanced hardness reduces bendability |

⭐⭐⭐⭐⭐ James Wilkins - Structural Fabricator

"We’ve been using the Pro Model PPGI coils for coastal infrastructure projects since June 2024, and after 7 months of exposure to salt spray and high humidity, there’s zero sign of corrosion. The Z60 coating and UV-resistant finish are game-changers. We’re now standardizing this material across all marine-facing builds."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Mehta - Home Metalworking Enthusiast

"I bought the Base Model in February 2025 to build custom garden fencing and a small toolshed. The 901mm width fit my roll former perfectly, and the ±1% tolerance meant clean, seamless corrugated panels. The pre-painted finish saved me hours of painting—looks professional and holds up great in rain. For a DIYer like me, the balance of cost and quality is spot-on."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Carlos Mendez - Production Manager, Industrial Containers Ltd.

"Switched to these DX52D-grade PPGI coils in September 2024 for container fabrication. The mid-hard steel is easy to punch and form without cracking, and the Z50 coating has held up better than our previous supplier’s material. Only reason I’m not giving 5 stars is that lead time was two weeks longer than expected during our first order. But the product quality? Absolutely solid."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Custom Home Builder

"Used the Advanced Model for decorative roofing panels and exterior cladding on a modern farmhouse project. Purchased in November 2024, and after 6 months of freeze-thaw cycles and heavy rainfall, the finish remains flawless. The ability to customize the color to match the client’s vision was a huge plus. This isn’t just functional—it’s architectural-grade material."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Takashi Ito - Engineering Lead, Precision Machinery Co.

"We needed a durable, formable steel for protective housings on outdoor-rated machinery. The DX52D + Enhanced Alloy in the Pro Model delivers the 410 MPa tensile strength we required, and the surface hasn’t chipped during assembly or transport. The EN certification also simplified our compliance documentation. A rare find—industrial toughness with aesthetic precision."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Lena Fischer - Corrosion & Materials Specialist

"Few prepainted galvanized coils meet both EN 10169 for coating and EN 10149 for structural performance. These do—and exceed them. The Z60 variant’s triple corrosion resistance over bare steel makes it ideal for aggressive environments. I recommend the Pro Model for any application where longevity outweighs initial cost."

Marcus Bell - Green Building Advisor

"With tightening regulations on material durability and lifecycle emissions, these coils stand out. Their long service life, recyclable steel base, and low-maintenance finish contribute to LEED points in material selection. For sustainable industrial builds, I now specify this product by default."

Posted: 2 days ago

"Using the Pro Model in a northern mining camp. Survived -30°C winters and spring thaws with no coating degradation. Worth every penny for reliability."

Posted: 10 days ago

"Ordered custom 950mm coils for corrugated roofing. Tolerance was dead-on. No rework, no waste. Their precision is unmatched."

Posted: 3 weeks ago

"Used for a public art installation with exposed steel elements. The color consistency and weather resistance are excellent. Slight delay in sample delivery, but final product exceeded expectations."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.