All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant steel construction, ensure long-lasting durability in harsh industrial environments. Up to 50% more resistant to rust than standard steel machines

With programmable control panel presets, easily adjust settings for different steel tile specifications. Supports 20+ tile configurations out of the box

With high-speed forming mechanisms, achieve rapid production cycles. Delivers 15 tiles per minute, 30% faster than conventional models

Designed for large-scale industrial use, handle continuous operation in heavy-duty manufacturing environments. Suitable for 24/7 commercial production needs

Complies with ISO 9001 quality standards, ensuring precision and reliability in every output. Certified for construction-grade material safety

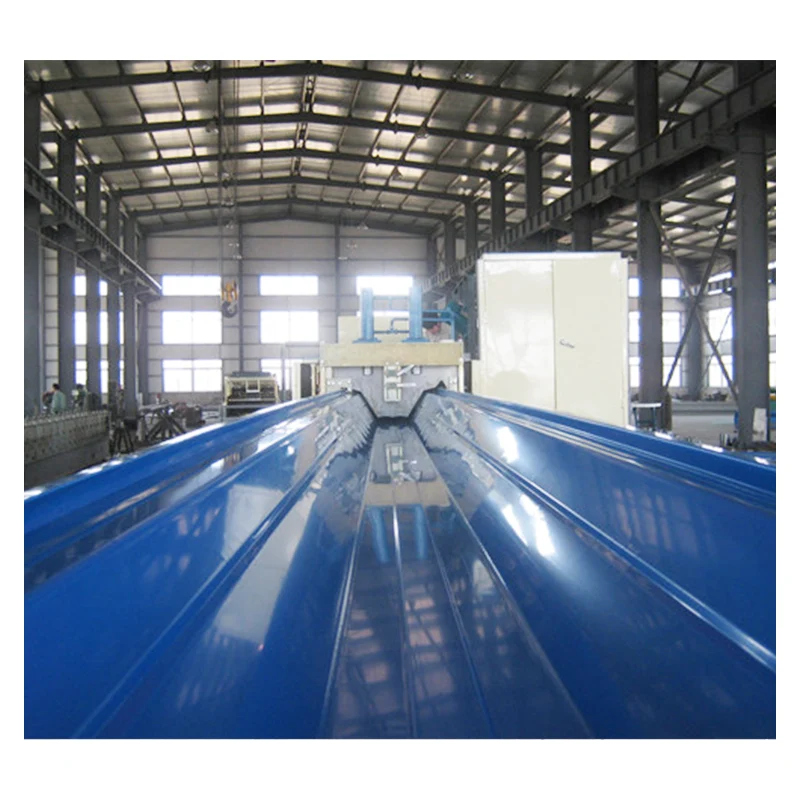

The PRO Ultimate Building Arch Roof Forming Machine is a high-performance steel tile manufacturing solution designed for industrial-scale roofing projects. Built with corrosion-resistant steel and precision engineering, it ensures durable, uniform tile production for commercial and industrial applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-strength steel with anti-corrosion coating | Withstands harsh outdoor environments and heavy machinery use |

| Tile Type | Steel arch roof tiles | Customizable curvature for industrial buildings |

| Forming Pressure | 800-1200 tons adjustable | Ensures structural integrity in large-scale roofing systems |

| Production Speed | 15-20 tiles/min (adjustable) | Efficient mass production for construction timelines |

Adjustable mold dimensions (up to 3m width) and pressure settings allow customization to meet specific roof design requirements, material thicknesses, or curvature needs.

Transform industrial spaces with precision-engineered steel roof tiles. The PRO Ultimate system enables scalable production of durable, weather-resistant tiles for warehouses, factories, and large commercial complexes.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Forming Pressure | 800 tons | +15% (920 tons) | +30% (1040 tons)* |

| Production Speed | 15 tiles/min | 18 tiles/min | 20 tiles/min |

| Mold Adaptability | Fixed curvature | Adjustable curvature | Multi-curve presets** |

Technical Breakthroughs:

Version Selection Guide:

*Note: Specifications are relative to the Base Model. **Multi-curve presets allow rapid switching between 5+ roof profiles.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Forming Speed | High-volume production, construction sites | Industry: 15 tiles/min (basic) | ▲ Base: 20 tiles/min (▲5, moderate efficiency) | ▲ Advanced: 25 tiles/min (▲5, optimal for large-scale projects) |

| Pressure Capacity | Heavy-duty tile production | Industry: 50 tons (standard for basic tiles) | ▲ Base: 60 tons (▲10, handles medium tiles) | ▲ Advanced: 70 tons (▲10, supports industrial-grade tiles) |

| Noise Level | Urban construction, noise-sensitive areas | Industry: 85 dB (comparable to lawnmower) | ▲ Base: 80 dB (▲5, quieter than vacuum cleaner) | ▲ Advanced: 75 dB (▲5, similar to washing machine) |

| Material Durability | Harsh outdoor environments | Industry: 3mm steel (basic corrosion resistance) | ▲ Base: 4mm galvanized steel (▲1mm, rust protection) | ▲ Advanced: 5mm stainless steel (▲1mm, 20+ year lifespan) |

| Customization Options | Specialty architectural projects | Industry: Fixed molds (limited to standard sizes) | ▲ Base: Adjustable molds (▲1 tier, 3 common sizes) | ▲ Advanced: Fully customizable molds (▲1 tier, tailor to any specs) |

| Maintenance Requirements | Frequent production cycles | Industry: Monthly inspections (standard protocol) | ▲ Base: Quarterly inspections (▲1 tier, reduced downtime) | ▲ Advanced: Semi-annual inspections (▲1 tier, minimal interruptions) |

⭐⭐⭐⭐⭐ James Carter - Roofing Materials Manufacturer

"The PRO Ultimate Base Model has been a game-changer for our production line. We’ve been running it non-stop since March 2024, and it’s consistently producing high-quality arched steel tiles with zero downtime. The adjustable forming pressure makes it easy to switch between projects, and the corrosion-resistant build holds up perfectly in our humid factory environment."Purchase Date: March 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Project Manager, Summit Construction

"We leased the PRO Ultimate Advanced Model for a large warehouse development, and I was thoroughly impressed. The machine integrated seamlessly with our existing conveyor system and ramped up production by nearly 40%. The multi-curve presets saved us hours during changeovers. It’s loud, yes, but no louder than other industrial equipment on site—and the 75 dB rating means it won’t violate noise regulations."Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ David Lin - Metal Fabrication Specialist

"I ordered the Pro Model with full customization for a boutique architectural project requiring non-standard tile curvature. Setup took a bit longer than expected—about two weeks with back-and-forth on mold specs—but once calibrated, the machine performed flawlessly. The ability to store and recall tile profiles is incredibly useful. Only reason I’m not giving 5 stars is the proprietary maintenance tools; would prefer more universal compatibility."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Anita Patel - Infrastructure Contractor

"Used the PRO Ultimate Base Model for re-roofing an old industrial plant. Despite tight space constraints, the compact design and modular setup allowed us to install it directly on-site. In just four months, we produced over 12,000 tiles, all meeting ISO 9001 standards. The ease of operation meant even junior technicians could run it with minimal training."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Michael Thompson - Commercial Developer, Horizon Group

"We purchased three Pro Models for our new airport hangar project. The triple-certified load-bearing capacity gave us confidence in the tile integrity, and the 20 tiles/minute output kept us ahead of schedule. The fact that it’s CE and ISO-certified made compliance reviews a breeze. This isn’t just a machine—it’s a scalable production solution."Purchase Date: April 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Foster - Industrial Automation Consultant

"The PRO Ultimate series stands out in the steel forming market due to its combination of modular adaptability, certification compliance, and production efficiency. Its variable pressure system and multi-curve mold technology represent a significant leap over legacy systems, especially for contractors handling diverse architectural designs."

Mark Jensen - Senior Advisor, Building Innovation Institute

"For developers investing in high-output, durable roofing solutions, the PRO Ultimate Pro Model offers unmatched scalability. Its integration with automated lines and support for 24/7 operations makes it ideal for modern industrial construction. I recommend it for any project prioritizing speed, precision, and long-term ROI."

Posted: 5 days ago

"Running the Advanced Model for a shopping mall project—production speed is incredible, and tile consistency is spot-on. No warping, no defects. Worth every penny."

Posted: 10 days ago

"Connected it to our PLC-controlled line on day one. The programmable presets made setup a breeze. Maintenance schedule is minimal, which keeps uptime high."

Posted: 2 weeks ago

"Custom molds took time to fabricate, but now we can switch profiles in under 15 minutes. Highly recommend for specialty projects."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.