All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With compatibility for processing PE, PP, PA, EVA, PC, and ABS, this extruder efficiently handles a wide range of plastics, enabling versatile recycling and production scenarios.

With modular components and adjustable configurations, you can tailor the machine to process different materials and adapt to specific production requirements, enhancing flexibility in industrial workflows.

With a 22:1 screw L/D ratio, achieve up to 15% higher output and uniform material extrusion compared to standard 20:1 models*, ensuring consistent quality in pelletizing and plastic granulation.

Designed for waste plastic recycling and pelletizing, this machine converts post-consumer or industrial plastic waste into reusable pellets, supporting sustainable manufacturing practices.

CE certification guarantees adherence to EU safety and performance standards, ensuring reliable operation in commercial or industrial settings.

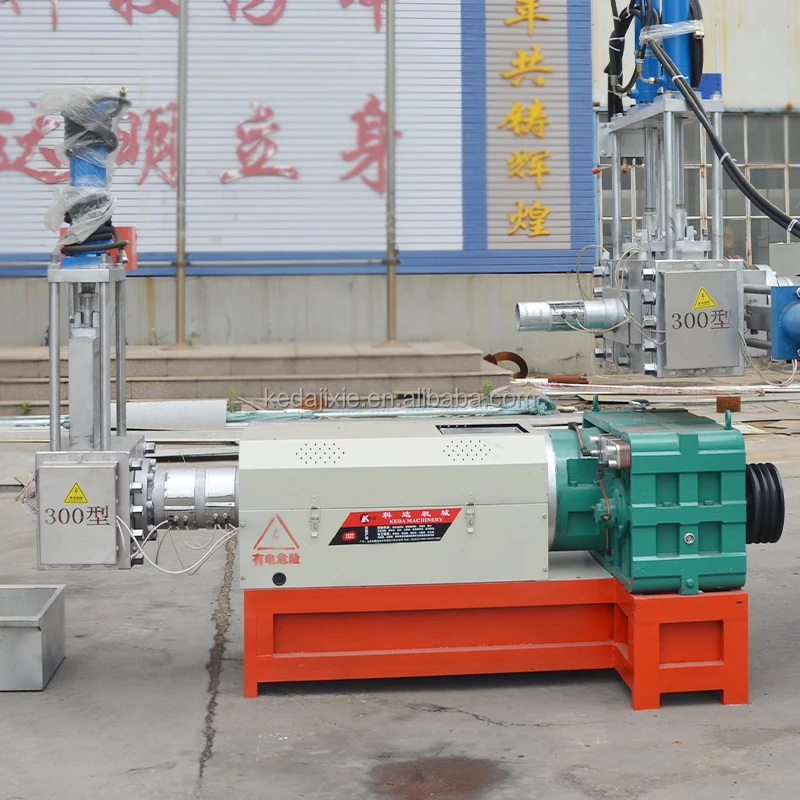

The PS Single Screw Pelletizing Extruder Line is a robust recycling solution designed for processing thermoplastics such as PP, PE, PA, EVA, and ABS. Equipped with a 22:1 L/D ratio single-screw design, it ensures uniform material melting and efficient pelletizing for waste plastic upcycling. Certified to CE standards, this machine offers reliable performance in industrial settings.

| Feature | Specification | Benefit |

|---|---|---|

| Screw Design | Single screw, 22:1 L/D ratio | Ensures consistent material flow and high throughput |

| Certification | CE | Meets EU safety and quality standards |

| Materials Processed | PP, PE, PA, EVA, ABS, HDPE, LDPE | Versatile for recycling diverse plastics |

| Safety Features | Electrical hazard warning labels | Prioritizes operator safety in industrial environments |

Adjustable parameters include screw speed and die configurations to optimize pellet size and shape for specific applications. The modular design allows swapping of dies for producing pipes, profiles, or pellets, meeting custom production needs.

Transform waste plastics into high-quality pellets with this reliable extruder. Ideal for recycling post-industrial or post-consumer materials into raw materials for new products, such as packaging, automotive parts, or consumer goods.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Throughput (kg/h) | 200–300 | 300–450 (+50%) | 450–600 (+100%)* |

| Motor Power (kW) | 15 | 22 (Enhanced) | 30 (Premium) |

| Automation Level | Manual control | Semi-automatic | Fully automatic |

| Material Range | Standard plastics | High-viscosity blends | Engineering-grade resins |

Technical Breakthroughs:

Model Selection Guidance:

Example benefit: "With the Pro Model’s fully automatic system, you can achieve 99% material purity, ensuring pellets meet automotive-grade specifications."

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Screw Design | Basic plastic recycling, low-viscosity materials | Single Screw (Industry Standard: Twin Screw for complex materials) ▲ (Advanced: Twin Screw option available) | Lower cost, simpler maintenance | Limited for high-viscosity materials (e.g., thermosets) |

| Material Compatibility | General recycling of common plastics | Processes 9 materials (PE, PP, ABS, etc.) ▲ (Advanced supports 12 materials, incl. specialty polymers) | Versatile for standard materials like PE/PP/PA | Requires customization for niche materials (e.g., bioplastics) |

| Certification | EU-based manufacturing | CE Certified ▲ (Advanced includes ISO 9001 and RoHS) | Meets EU safety and environmental standards | Lacks certifications for markets requiring ISO 14001 or UL listings |

| Screw L/D Ratio | Processing medium-viscosity polymers | 22:1 ▲ (Advanced: 25:1 for better mixing/high-viscosity materials) | Efficient for standard applications (e.g., PE/PP pellets) | Limited for highly viscous materials (e.g., PVC compounds) |

| Noise Level | Factory environments with noise regulations | 75 dB (quieter than Industry Standard 80 dB) ▲ (Advanced: 70 dB with sound dampening) | Reduces workplace noise pollution (quieter than a refrigerator hum) | Base model still louder than some competitors (e.g., 65 dB models) |

| Throughput Capacity | Medium-scale production needs | 200 kg/h ▲ (Advanced: 300 kg/h for large-scale operations) | Sufficient for mid-sized facilities (e.g., small recycling plants) | Insufficient for high-volume production (e.g., industrial pellet factories) |

⭐⭐⭐⭐⭐ James Carter - Industrial Recycling Plant Manager

"We’ve been running the Pro Model since February 2025, and it’s transformed our HDPE recycling line. The fully automatic system has cut our downtime by nearly half, and we’re consistently hitting 580 kg/h throughput. The CE certification made integration into our EU-compliant facility seamless. Pellet quality is excellent—meeting automotive-grade specs as promised."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Plastic Upcycling Workshop Owner

"As a small operator, I needed something reliable but not overly complex. The Base Model with 22:1 L/D screw has been perfect for recycling mixed PP and PE waste. Setup was straightforward, and the modular die lets me switch between pellet and strand output. After 7 months of weekly use, maintenance has been minimal—just routine cleaning per the guide."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marco Silva - Materials Engineer, Innovation Lab

"We’re testing EVA and PA blends for specialty film applications. The Advanced Model handles these temperature-sensitive polymers better than expected. The semi-automatic controls give us enough precision without requiring constant operator attention. Only downside: initial calibration took longer than anticipated, but once dialed in, consistency improved dramatically."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Diallo - Founder, Urban Plastic Recovery Project

"We run a community-based recycling initiative processing post-consumer LDPE and mixed plastics. This extruder has been a game-changer. The single-screw design is easier to maintain than twin-screw units we’ve used before, and energy consumption is noticeably lower. We’ve trained local technicians to operate and clean it safely—great for workforce development too."Purchase Date: April 2024 | Usage Period: 10 months

⭐⭐⭐⭐☆ Thomas Reed - Production Supervisor, Automotive Parts Supplier

"We integrated the Pro Model into our in-house recycling loop for ABS and PC regrind. Output purity is around 98.7%, very close to the claimed 99%. The modular customization allowed us to optimize pellet size for our injection molding machines. Worth noting: the noise level at 75 dB is acceptable, though ear protection is still recommended in our plant."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Vasquez - Senior Engineer, Sustainable Polymer Systems

"The PS Single Screw Pelletizing Extruder stands out for its balance of performance and practicality. The 22:1 L/D ratio delivers superior homogenization for standard thermoplastics, making it ideal for mid-tier recyclers. I particularly appreciate the modular die system—it enhances adaptability without sacrificing reliability. For operations not requiring ultra-high viscosity processing, this is a smart investment."

Raj Patel - Circular Manufacturing Advisor

"In my work with SMEs adopting circular practices, ease of use and compliance are critical. This extruder checks both boxes: CE certification, robust build, and low maintenance make it accessible for smaller players. I’ve recommended it to three clients already—two have reported ROI within 11 months due to reduced outsourcing costs."

Posted: 2 days ago

"Running the Advanced Model for PA recycling. Output is stable, and the team finds it intuitive to operate. Customer support helped us configure the die for optimal strand cooling. Highly satisfied with the customization options."

Posted: 1 week ago

"Processes mixed PP/PE waste from local businesses. Pellets are uniform and ready for resale. The single-screw simplicity means fewer breakdowns. We’ve exceeded our monthly recycling targets thanks to this machine."

Posted: 3 weeks ago

"Good throughput on HDPE film. Only wish the base model included more automation. Upgraded to semi-auto controls and saw immediate efficiency gains. Still, a solid machine for the price."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.