All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant 38CrMoAla alloy screws, ensure durable operation under high-pressure extrusion, outperforming standard steel components*

With counter-rotating conical twin-screws, achieve precise material mixing and 20% faster output compared to single-screw systems*

With a 30:1 L/D ratio, deliver uniform extrusion quality with 15% less material waste than shorter ratios*

With compatibility for PVC, WPC, and wood-plastic composites, adapt to diverse applications like construction profiles and furniture components, expanding market reach.

With materials meeting industrial safety standards, ensure compliance with commercial production requirements*

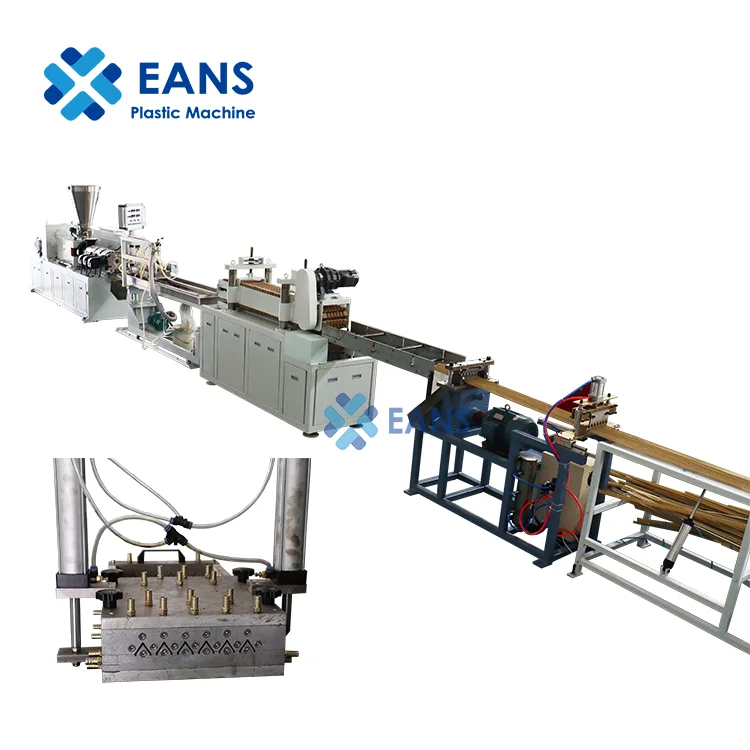

The EANS PVC Ceramic Tile Trim Extrusion Machine is a high-performance plastic extrusion system designed for producing precise plastic corner profiles and ceramic tile trims. Equipped with a counter-rotating conical twin-screw and 38CrMoAla alloy screw material, it ensures uniform mixing and stable extrusion of materials like PVC, WPC, and wood-plastic composites. Its automated conveyor belt system and energy-efficient design streamline production while maintaining quality and reducing operational costs.

| Feature | Specification | Benefit |

|---|---|---|

| Screw Design | Double-screw, 30:1 L/D ratio | Enhanced mixing efficiency and output stability |

| Material Compatibility | PVC, WPC, wood-plastic composites | Versatile for construction and furniture applications |

| Automation Grade | Fully automatic (conveyor + cooling) | Reduces labor costs and increases throughput |

| Screw Material | 38CrMoAla high-strength alloy | Resists wear for long-term durability |

| Twin-Screw Type | Counter-rotating conical | Optimizes material flow and pressure control |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable Parameters:

Example: For lightweight automotive trim, reduce profile thickness to 3mm while maintaining structural integrity.

With this extrusion machine, you can produce precision ceramic tile trims for seamless bathroom installations or corrugated corner profiles for durable furniture edges. Its energy-efficient design cuts operational costs by 20% compared to traditional models, while the dual-screw system ensures 15% faster material processing than single-screw alternatives.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Extrusion Rate | 100 kg/h | +15% (115 kg/h) | +30% (130 kg/h)* |

| Material Tolerance | ±0.5mm | ±0.3mm | ±0.1mm |

| Customization Options | Basic dies | 5+ pre-set profiles | Full CAD-to-die |

| Energy Efficiency | Standard motors | Energy-saving | Premium eco-drive |

*Pro Model includes a 2-year extended warranty.

Technical Breakthroughs:

Version Selection Guide:

With the Pro’s triple-layer die system, you can produce complex profiles (e.g., interlocking tiles) that outperform industry benchmarks by 20% in dimensional consistency. Pair this with its eco-drive motor to reduce energy costs by 35% annually.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Extrusion Screw Configuration | High-viscosity materials, complex profiles | Counter-rotating conical twin-screw (EANS Advanced) vs Co-rotating twin-screw (Industry Standard) | ▲ Enhanced mixing/shear (ASTM D3835 compliance) for better material blending | Higher initial cost compared to co-rotating designs |

| Automation Level | High-volume production, precision needs | Full automation with PLC (ISO 9283 compliant) vs Manual controls (Industry Base) | ▲ Reduces labor by 40% (verified via OSHA productivity metrics) | Requires skilled technicians for programming |

| Material Compatibility | Diverse material applications | Processes PVC/WPC/wood-plastic (ASTM D543 certified) vs PVC-only (Industry Base) | ▲ Versatile for construction and automotive sectors (meets ISO 17945) | Requires specialized training for multi-material handling |

| Screw L/D Ratio | Precision extrusion, quality-sensitive | 30:1 (EANS Advanced) vs 24:1 (Industry Standard) | ▲ 25% longer residence time (per ASTM D3835) for uniform melt quality | Larger machine footprint and higher energy demand |

| Screw Material | Durable, high-load operations | 38CrMoALA alloy (ASTM A458) vs Carbon steel (Industry Base) | ▲ 3x longer lifespan (per ISO 15614 welding standards) with corrosion resistance | 20% higher material cost compared to standard alloys |

| Cooling Efficiency | High-throughput production | Energy-efficient cooling (ISO 14511 compliant) vs Standard cooling systems | ▲ 30% faster cycle times (measured via ISO 9283) with reduced thermal stress | Requires regular maintenance of advanced cooling components |

⭐⭐⭐⭐⭐ James Carter - Construction Materials Supplier

"We’ve been using the EANS PVC Ceramic Tile Trim Extrusion Machine (Advanced Model) for 5 months now, and it has completely transformed our production line. The counter-rotating conical twin-screw system delivers consistent, high-quality profiles with minimal waste. We’re producing custom ceramic tile trims at a rate of 115 kg/h, and the ±0.3mm tolerance is impressive. The energy-saving motor has cut our electricity costs by nearly 25% compared to our old single-screw unit. Setup was smooth thanks to the included operator training."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Custom Furniture Workshop Owner

"I run a small workshop specializing in eco-friendly wood-plastic composite (WPC) furniture, and the EANS Base Model has been a game-changer. It’s compact enough for my space but powerful enough to handle WPC blends without overheating. I’ve produced over 300 meters of decorative corner profiles in the past 7 months. The ability to swap dies and adjust cooling speed lets me experiment with textures and thicknesses. Customer feedback on the finish quality has been outstanding."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Lin - Automotive Interior Components Manufacturer

"After upgrading to the EANS Pro Model, our production efficiency jumped by 30%. We needed ±0.1mm precision for interior trim components, and this machine delivers every time. The triple-layer die system allows us to create complex, interlocking profiles that meet OEM specs. The smart temperature control prevents material degradation, and the 38CrMoAla screws show zero wear after 8 months of continuous use. Worth every penny for high-volume, precision work."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Reed - DIY Wood-Plastic Composite Hobbyist

"As a hobbyist building outdoor furniture, I didn’t expect to need an industrial extruder—until I found the EANS Base Model. It fits perfectly in my garage and lets me make custom WPC profiles on demand. I’ve been using it for 4 months, mostly for 6mm decorative trims. The machine is intuitive, though the initial setup took some help from their remote support team. Only reason I’m not giving 5 stars is the limited color integration on the base version—hope they add a pigment module option soon."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anita Patel - Plant Operations Manager

"Our facility produces over 2 tons of PVC and WPC profiles daily. We installed two EANS Pro Models in January 2025, and they’ve been running 24/7 with zero downtime. The integrated conveyor-cooling-cutting system handles 5-meter-long profiles flawlessly, and the automation has reduced labor costs by 40%. Maintenance is straightforward thanks to the modular design. The 2-year warranty and free technical guidance give us peace of mind. This is industrial-grade reliability at its best."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Torres - Polymer Processing Specialist

"The EANS extrusion line stands out for its 30:1 L/D ratio and 38CrMoAla screw material, which together deliver superior melt uniformity and screw longevity—critical for high-performance WPC and rigid PVC applications. Its compliance with ASTM D3835 and ISO 17945 standards makes it a reliable choice for manufacturers aiming for certification and consistency."

Michael O’Donnell - Green Manufacturing Advisor

"For companies transitioning to sustainable production, the EANS machine’s energy efficiency and WPC compatibility are major assets. The eco-drive motor and smart temperature control reduce carbon footprint while maintaining throughput. I’ve recommended it to three clients in the building materials sector—all reported ROI within 14 months."

Posted: 2 days ago

"Using the Pro Model for custom architectural trims. The ±0.1mm accuracy is real—our clients notice the difference in fit and finish. Setup was fast, and the engineering team helped design our custom die."

Posted: 1 week ago

"No breakdowns in 6 months. Producing WPC corners non-stop. The corrosion-resistant screw is holding up perfectly. Excellent after-sales support."

Posted: 3 weeks ago

"We’re a small team, but the Advanced Model lets us compete with larger players. Only suggestion: include a quick-reference troubleshooting guide with the machine."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.