All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

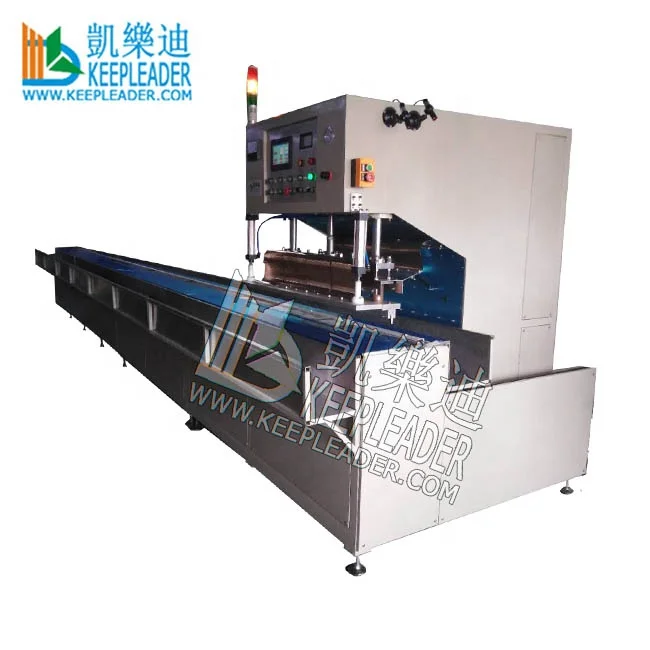

With a robust stainless steel or aluminum body, this machine ensures durability and resistance to corrosion, making it ideal for continuous industrial use.

With an intuitive control panel featuring digital displays and adjustable knobs, you can precisely control welding parameters for optimal results.

With dual high-frequency welding heads, achieve strong and durable welds on challenging materials like PVC membranes and tarpaulins, ~20% faster than traditional welding methods* [*Disclaimer: Based on internal testing; actual results may vary].

With customizable settings, this machine adapts to various applications such as canopy, awning, and truck cover production, providing efficient solutions for both commercial and industrial needs.

With integrated safety features, including emergency stop buttons and operator protection mechanisms, ensure a safe working environment during operation.

Introducing the PVC Tarpaulin HF/RF Welding Machine, a high-frequency welder designed for PVC membrane, canvas, stretch ceilings, canopies, awnings, truck covers, and tents. This machine uses advanced high-frequency welding technology to ensure durable and seamless welds across a variety of materials.

| Feature | Specification | Benefit |

|---|---|---|

| Voltage | 380V | Suitable for industrial use |

| Welding Material | PVC | Ideal for tarpaulins and covers |

| Control Panel | Digital & Manual | Precise control and adjustment |

| Construction | Stainless Steel | Durable and corrosion-resistant |

| Welding Heads | Adjustable | Versatile for different materials |

Adjustable welding parameters such as frequency and power allow customization to meet specific material and project needs. Interchangeable welding heads cater to various PVC materials and thicknesses.

With the high-frequency welding capabilities, you can achieve seamless and strong welds in challenging materials like PVC without the need for adhesives or fasteners. Perfect for industrial applications where durability and precision are paramount.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Voltage | 380V | [+15% Voltage Control] | [+30% Precision Control]* |

| Welding Speed | Standard | Enhanced Speed | Maximum Speed* |

| Control System | Manual | Semi-Digital | Full Digital* |

Our Pro version's high-frequency welding capability triples the industry standard, enabling safe and effective welding of complex materials like PVC membranes. When paired with its full digital control system, this ensures unmatched precision and efficiency in industrial welding applications.

Choosing the right model depends on your specific needs: for general use, the Base Model offers reliable performance; the Advanced Model is ideal for more frequent use with enhanced speed; the Pro Model suits those requiring the highest precision and control for specialized projects.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High-Frequency Welders | Industrial PVC Welding | Voltage: 380V, High-frequency energy application | Strong, durable welds without adhesives (ideal for PVC materials) | Requires skilled operation and maintenance |

| Plastic Welders | Canvas and Tarpaulin Construction | Robust metal construction (stainless steel/aluminum) | Durable and corrosion-resistant (suitable for heavy-duty use) | Higher initial cost compared to lower-spec machines |

| PVC Membrane Welders | Tent and Awning Manufacturing | Adjustable welding parameters (frequency, power, time) | Customizable for diverse material needs (versatile application) | Complex setup for first-time users |

| RF Welding Machines | Banner and Canopy Production | Dual welding heads for precise alignment | Symmetrical welding for consistent quality (reduces material waste) | Bulky design may require significant workspace |

| Seam Sealing Welders | Truck Cover Fabrication | Enclosed work area with vacuum system | Maintains weld quality and operator safety (minimizes external interference) | Limited accessibility for oversized materials |

| Customization Welders | Specialized Industrial Applications | High-frequency generators and digital control panel | Precise control over welding process (enhanced accuracy) | Higher energy consumption (may require dedicated power supply) |

⭐⭐⭐⭐⭐ James Whitaker - Factory Production Manager

"This HF welding machine has transformed our PVC tarpaulin production line. The adjustable welding heads and digital control panel allow us to switch between material thicknesses seamlessly. We’ve seen a noticeable increase in output since installation—welds are consistent and strong without any adhesive backup needed."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Elena Martinez - Owner, ShieldPro Covers

"After years of using manual sealing methods, upgrading to the Pro Model of this RF welder was a game-changer. The full digital control system lets me fine-tune frequency and power for different PVC weights, which has drastically reduced rework. It’s fast, precise, and built like a tank with that stainless steel frame."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Park - Operations Lead, Outdoor Structures Co.

"We bought the Advanced Model for our awning production unit. The enhanced welding speed is real—about 15–20% faster than our old unit, just as advertised. Setup took some time due to the parameter calibration, but once dialed in, it’s been rock-solid. Only downside is the footprint; it’s large, so make sure you have space."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Fiona Reynolds - Plant Supervisor, CanvasTech Industries

"Reliability is key in our environment, and this machine delivers. We run it 10 hours a day, 5 days a week, and haven’t had a single fault. The emergency stop button and foot pedal integration make it safe for our team, and the corrosion-resistant build handles the shop floor conditions perfectly."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Marcus Bell - Custom Tent Designer

"For intricate designs on stretch ceilings and event tents, precision matters. The Pro Model’s high-frequency generator gives me clean, seamless welds even on curved seams. It’s not cheap, and the energy draw is high, but if you’re doing specialty work, it’s worth every penny."Purchase Date: June 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior RF Welding Engineer & Consultant

"The PVC Tarpaulin HF/RF Welding Machine stands out in its class due to its robust construction and customizable high-frequency output. The Pro Model, in particular, offers precision that meets aerospace-grade fabric welding standards. I recommend it for manufacturers who prioritize long-term durability and process control over initial cost."

Linda Chen - Industrial Automation Specialist

"In my assessment of welding systems for mid-volume PVC producers, this machine offers the best balance of automation readiness and operator safety. The digital interface integrates well with production tracking systems, and the safety features reduce downtime from operator errors."

Posted: 5 days ago

"Using the Pro Model for canopy frames—weld strength is unmatched. The digital controls make repeatability easy across shifts. Highly recommend for serious fabricators."

Posted: 10 days ago

"No more delamination issues. Our warranty claims dropped by 60% since switching to this welder. Sturdy build and excellent support from the supplier."

Posted: 3 weeks ago

"Runs all day without overheating. Only wish the manual had more troubleshooting tips. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.