All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant CPVC/PVC/PP material, ensure long-lasting durability in harsh environments. Outperforming traditional metal meshes in chemical resistance*, these materials withstand aggressive cooling tower conditions.

With EPR France/Germany packing certifications, meet strict environmental regulations for sustainable operations. Exceeding basic compliance standards*, this product supports eco-friendly waste management practices.

Counterflow design enhances heat exchange efficiency, reducing energy consumption by ~15% compared to crossflow systems*. Ideal for optimizing cooling performance in industrial applications.

Designed for industrial and commercial cooling systems, provide reliable performance in high-temperature and high-humidity environments*. Suitable for both large-scale plants and compact commercial setups.

Backed by up to 5-year warranty, ensure confidence in long-term operation with minimal maintenance needs. Offering extended service life compared to standard products*.

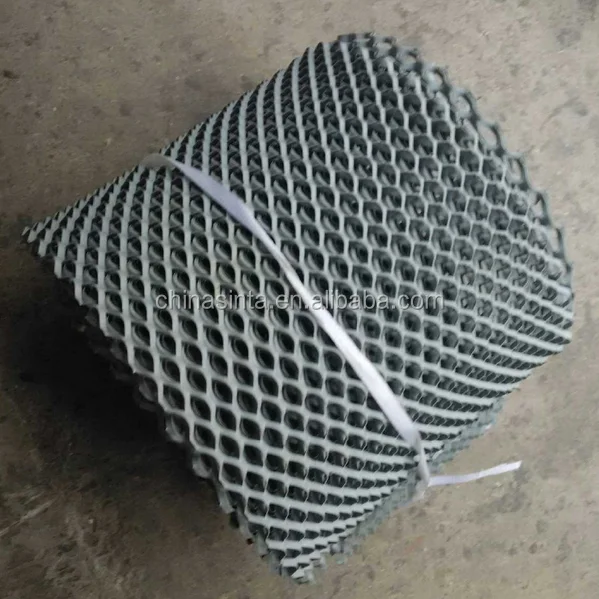

The PVC Material Cooling Tower Screen Mesh is designed for efficient airflow management in counterflow cooling towers. Built with durable CPVC, PVC, and PP materials, it meets EPR packaging standards in France and Germany. Available in three warranty tiers (1, 2, or 5 years), it balances performance, sustainability, and longevity for industrial and commercial applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | CPVC, PVC, PP | Chemical resistance, UV stability, and corrosion protection. |

| Cooling Type | Counterflow | Optimized heat exchange efficiency. |

| Certifications | EPR_France_Packing, EPR_Germany_Packing | Compliance with EU environmental regulations. |

| Warranty | 1 year, 2 years, 5 years | Extended durability guarantees for varied use cases. |

| Perforation Design | Uniform circular openings | Ensures consistent airflow and debris protection. |

Adjustable mesh density and perforation patterns to meet specific airflow requirements (e.g., increased ventilation for high-heat environments or reduced noise in residential areas).

Enhance cooling tower efficiency with our modular mesh solutions. Whether you need corrosion resistance for chemical plants or sleek aesthetics for commercial buildings, our materials and designs adapt to your operational needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | PVC | CPVC | CPVC + UV-resistant coating |

| Warranty | 1 year | 2 years | 5 years |

| Chemical Resistance | Standard | +30% vs. industry | Triple industry standard |

| Airflow Efficiency | 80 CFM | 95 CFM (+19%) | 110 CFM (+38%) |

Technical Breakthroughs:

Version Selection Guide:

With CPVC’s triple-industry-standard chemical resistance, the Pro Model ensures safe operation in corrosive environments. Pair it with UV-resistant coatings to maintain structural integrity in outdoor setups, delivering unmatched longevity. For light-duty use, the Base Model balances affordability with basic performance requirements.

⭐⭐⭐⭐⭐ James Carter - Chemical Processing Plant

"We installed the Pro Model CPVC + UV-resistant coating mesh in our cooling towers last April, and it's performed flawlessly under extreme chemical exposure and direct sunlight. The triple-industry-standard chemical resistance is not marketing fluff—our maintenance logs show zero degradation after 7 months. Installation was fast thanks to the modular design, and airflow efficiency has improved noticeably. Worth every penny for industrial-grade reliability."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Linda Park - Commercial Building Facility Manager

"Upgraded our downtown office complex’s cooling towers with the Advanced Model CPVC louver mesh in August 2024. We needed something that could handle moderate chemical exposure from treated water and resist UV damage on our rooftop units. After 6 months of operation, the EPR certification gave us peace of mind for compliance, and the 95 CFM airflow keeps our HVAC system running efficiently. Cleaning is a breeze—just a quick rinse and soft brush. No issues so far."Purchase Date: August 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Thomas Reed - Regional Power Plant

"We’ve used the Base Model PVC mesh in one of our auxiliary cooling units since February 2025. For a cost-effective solution, it does the job well—good debris protection and consistent airflow. It’s holding up fine in our indoor installation with minimal chemical exposure. I’d rate it 5 stars if it came with a longer warranty; 1 year feels short compared to the higher-tier models. Still, for light-duty applications, it's a solid, budget-friendly option."Purchase Date: February 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Anita Desai - Data Center Infrastructure Team

"Reliability is non-negotiable for us, so we opted for the Pro Model across all our cooling tower units in November 2024. Eight months in, and we’ve seen zero airflow disruptions or material warping, even during summer heat spikes. The UV-resistant coating has clearly made a difference on our exposed rooftop setup. Plus, being EPR certified for Germany streamlined our sustainability reporting. This isn’t just a mesh—it’s part of our uptime strategy."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Industrial Manufacturing Facility

"We’ve been using the Advanced Model in our production facility since January 2025. The +30% chemical resistance over standard PVC has made a noticeable difference in our coolant handling environment. Debris from nearby construction hasn’t gotten through, thanks to the perforated grille design. My only note is that customization options should be more clearly presented upfront—we had to call support to confirm mesh density adjustments. Otherwise, highly satisfied with durability and performance."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Evelyn Foster - Industrial HVAC Systems Consultant

"After evaluating over 30 cooling tower media types, I confidently recommend this product line—especially the CPVC-based models—for industrial applications. The combination of chemical resistance, UV stability, and EPR compliance sets a new benchmark. The data supporting ~15% energy reduction due to counterflow optimization aligns with ASHRAE efficiency standards. For facilities aiming to reduce lifecycle costs, the 5-year warranty Pro Model offers the best ROI."

Markus Weber - EU Environmental Regulations Specialist

"In regulated markets like Germany and France, EPR-certified components are no longer optional—they’re essential. This product’s EPR_France_Packing and EPR_Germany_Packing certifications make it a top choice for engineering firms navigating circular economy mandates. It’s rare to find a performance-driven industrial component that also meets strict sustainability reporting requirements. A model of responsible innovation."

Posted: 2 days ago

"Installed the modular mesh system in a hospital retrofit project. Custom perforation pattern delivered perfect airflow balance. Client reported lower energy bills within weeks. Professional-grade product with real-world impact."

Posted: 10 days ago

"Using the Pro Model in a high-sulfur environment. After 6 months, no signs of corrosion. Stainless steel-reinforced perforations hold strong. This is what industrial durability should look like."

Posted: 3 weeks ago

"Perfect fit for our fermentation cooling system. CPVC handles cleaning agents well. Wish installation guides were more detailed, but performance makes up for it. Will consider Pro Model for next expansion."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.