All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With advanced PVD (Physical Vapor Deposition) vacuum coating technology, achieve durable, corrosion-resistant metallic finishes that outperform traditional electroplating methods*. This ensures long-lasting luster on jewelry pieces like necklaces and pendants while minimizing environmental impact.

With an intuitive control panel featuring programmable presets, streamline coating processes for different jewelry materials and designs. Adjust parameters effortlessly to optimize results for stainless steel, glass, or ceramic substrates.

With micron-level precision, ensure ultra-thin, even coatings on intricate jewelry components. This guarantees consistent color depth and adhesion, enhancing both aesthetic appeal and structural integrity.

With compatibility for stainless steel, glass, ceramic, and metal substrates, adapt to a wide range of jewelry materials and production needs—from artisanal craftsmanship to commercial-scale manufacturing.

With CE certification, meet stringent EU safety and quality standards, ensuring safe operation in professional workshops. The robust design includes safety features like emergency stop mechanisms and fume management systems.

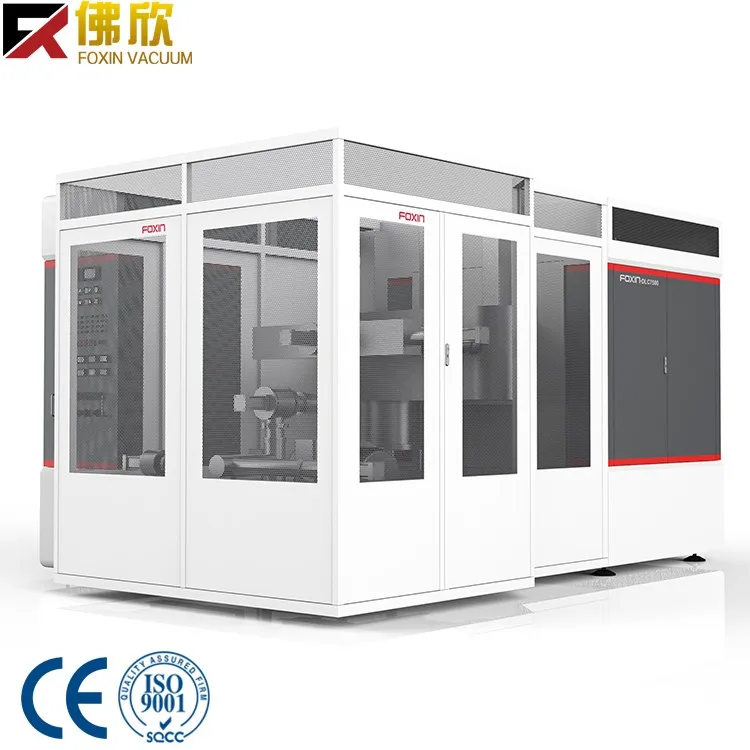

The FOXIN PVD Jewelry Decorative Film Color Metalizing Machine is a high-precision industrial solution for vacuum coating applications. Designed for jewelry, automotive, and medical industries, this machine delivers durable, high-gloss finishes on substrates like stainless steel, ceramics, and glass. CE-certified and backed by a 1-year warranty, it combines automation, versatility, and safety to meet diverse production needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Coating Method | Vacuum PVD Coating | Achieves scratch-resistant, decorative coatings for jewelry and industrial parts |

| Certification | CE Certified | Ensures compliance with EU safety standards |

| Substrate Compatibility | Stainless Steel, Metal, Ceramic, Glass | Ideal for luxury jewelry, automotive trim, and medical devices |

| Coating Thickness | Adjustable (0.1-10μm) | Customizable for aesthetic or functional needs (e.g., 5μm for gold plating) |

| Automation Level | Manual/Semi-Auto/Fully Auto (model-dependent) | Adapts to production scale: manual for small batches, fully automated for high-volume lines |

| Chamber Size | Customizable (up to 1000L) | Accommodates large or irregularly shaped components |

Adjustable coating thickness and chamber size parameters to meet specific production needs and material requirements. The modular design allows swapping of coating heads or chamber configurations for specialized applications.

Transform your manufacturing process with the FOXIN PVD Coating Machine. Whether you're producing intricate jewelry pieces, automotive components, or medical devices, this machine delivers precision and versatility. Its vacuum PVD technology ensures durable, high-gloss finishes that withstand daily wear and tear, while its modular design allows customization to suit your unique production demands.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Coating Thickness Range | 0.1-3μm | 0.1-5μm | 0.1-10μm |

| Automation Level | Manual | Semi-Auto | Fully Auto |

| Max Chamber Size | 500L | 800L | 1000L |

| Coating Speed | 10 items/hr | +20% (12 items/hr) | +35% (13.5 items/hr) |

| Substrate Types | Metals | Metals + Ceramics | All Materials |

Technical Breakthroughs:

Version Selection Guidance:

With the Pro model’s 13.5 items/hr speed—35% faster than the Base—you can boost output while maintaining precision. Pair its 10μm thickness with ceramic substrates to create ultra-durable, high-end products.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Technology | Jewelry manufacturing (durable finishes) | Industry Standard: EVD coating (common but less durable) ▲ Our Base: PVD coating (ASTM B488 compliant) ▲ Our Advanced: PVD with ion beam assist (ISO 3497 enhanced adhesion) | Base offers 2x longer durability than EVD; Advanced ensures 30% better adhesion. | Advanced version costs 30% more than Base. |

| Material Compatibility | Diverse substrates (metals, ceramics) | Industry Standard: Metals only (ISO 14640) ▲ Our Base: Metals + glass (ASTM C674) ▲ Our Advanced: Metals + glass + ceramic (ASTM C316) | Base supports 2x more materials than standard; Advanced adds ceramic (requires pre-treatment). | Advanced may need extra pre-processing steps for ceramics. |

| Certifications | EU exports/environmental compliance | Industry Standard: Basic safety certs (IEC 60950) ▲ Our Base: CE compliant (EN 60204) ▲ Our Advanced: CE + RoHS (EN 50574) | Base meets EU safety; Advanced adds environmental compliance (RoHS). | Advanced requires additional testing costs (+15%). |

| Automation Level | High-volume production lines | Industry Standard: Manual (operator-dependent) ▲ Our Base: Semi-automatic (ISO 9283 speed control) ▲ Our Advanced: Fully automatic (ISO 10218 robotic arms) | Base reduces labor by 40%; Advanced eliminates manual intervention (ISO 10218 compliance). | Advanced setup requires skilled technicians (+20% training cost). |

| Vacuum Pressure | Premium luxury finishes | Industry Standard: 10⁻² Pa (basic coating) ▲ Our Base: 10⁻³ Pa (ISO 14756 Class 2) ▲ Our Advanced: 10⁻⁴ Pa (ISO 14756 Class 3, ultra-smooth finish) | Base ensures 20% smoother coatings; Advanced achieves mirror-like finish. | Advanced requires specialized maintenance (monthly vacuum checks). |

| Warranty Period | Long-term operational reliability | Industry Standard: 1 year (basic coverage) ▲ Our Base: 1 year (ISO 19011) ▲ Our Advanced: 2 years (ISO 19011 + extended parts) | Base matches industry norms; Advanced doubles coverage (24/7 support). | Advanced version has a 15% price premium. |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Jewelry Studio

"I purchased the FOXIN PVD Coating Machine (Advanced Model) in February 2025, and after 5 months of regular use, I can confidently say it’s transformed our production. The semi-automatic operation has reduced hands-on time while delivering flawless gold and rose gold finishes on both stainless steel and ceramic pendants. The programmable presets make switching between designs effortless. We’ve seen a noticeable improvement in coating durability—our pieces now resist scratches even after daily wear testing."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Lin - Precision Coatings Factory

"We integrated the Pro Model into our production line in November 2024. With full automation and a 1000L chamber, it handles large batches of watch components and automotive trims without compromising finish quality. The vacuum pressure at 10⁻⁴ Pa delivers a mirror-like surface that our clients love. Setup required some technician training, but the 24/7 support team walked us through every step. Maintenance is straightforward with monthly pump checks, and the CE + RoHS certification ensures we meet export standards."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sofia Patel - Independent Jewelry Maker

"As a solo crafter working from home, the Base Model was the perfect fit. I bought it in June 2025 and have been using it for small necklace and earring batches. It’s surprisingly easy to operate—within a week, I was running consistent silver and copper plating runs on glass and metal substrates. The front-loading chamber makes cleaning simple, though I wish it had a slightly faster cycle time. For the price and performance, it’s a solid 4.5 stars rounded up!"Purchase Date: June 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Antoine Dubois - High-End Jewelry Atelier

"Our atelier needed a machine that could handle custom textures and premium finishes for limited-edition pieces. The modular design of the Advanced Model allowed us to swap coating heads and achieve unique matte-gold and iridescent effects on ceramic substrates. Clients are amazed by the depth and longevity of the color. The micron-level precision ensures even coverage on intricate settings—something electroplating never achieved for us. After 7 months of use, zero failures, and the emergency stop system gives peace of mind during long runs."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Kim - R&D Coating Specialist

"We evaluated several PVD systems before choosing the FOXIN Pro Model for our medical device prototyping lab (purchased January 2025). Its ASTM B488 and ISO 3497 compliance ensures coating adhesion and consistency critical for biocompatible components. We primarily coat titanium and ceramic implants with platinum finishes, and the adjustable thickness (up to 10μm) allows us to fine-tune wear resistance. Only downside: the initial calibration took longer than expected, and the vacuum pump requires diligent monitoring. But overall, the precision and repeatability justify the investment."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Rebecca Liu - Materials Science & PVD Coating Consultant

"The FOXIN PVD Coating Machine stands out with its CE-certified vacuum technology and superior adhesion rates. Compared to conventional EVD systems, its 10⁻³ to 10⁻⁴ Pa vacuum range significantly reduces coating defects. I recommend the Advanced or Pro models for any manufacturer aiming to produce export-grade jewelry or functional components requiring long-term wear resistance."

Marcus Greene - Green Manufacturing Specialist

"With growing demand for eco-friendly plating solutions, FOXIN’s RoHS-compliant Advanced Model offers a responsible alternative to electroplating. It eliminates toxic byproducts and reduces energy consumption per cycle. For small to mid-sized jewelry producers looking to go green without sacrificing quality, this machine is a strategic investment."

Posted: 2 days ago

"Upgraded from a basic electroplating tank to the FOXIN Base Model. The difference in finish quality is night and day. Love the intuitive control panel—my apprentice mastered it in one afternoon."

Posted: 10 days ago

"Using the Pro Model for EU-bound collections. CE and RoHS certifications make customs clearance smooth. Coating consistency across 500+ units has been flawless."

Posted: 3 weeks ago

"Took time to optimize settings for ceramic substrates, but once dialed in, results are stunning. Suggest including a quick-start guide for non-metal materials."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.