All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel construction, ensure long-lasting performance in demanding environments*

With an ergonomic manual adjustment knob, achieve precise control over ink distribution for optimal print consistency*

Maintain uniform ink flow rates across varying viscosities, ensuring high-quality prints on diverse materials*

Designed for uninterrupted commercial use, supporting high-volume printing without downtime*

Constructed with food-grade stainless steel, meeting strict hygiene standards for applications in food packaging and medical industries*

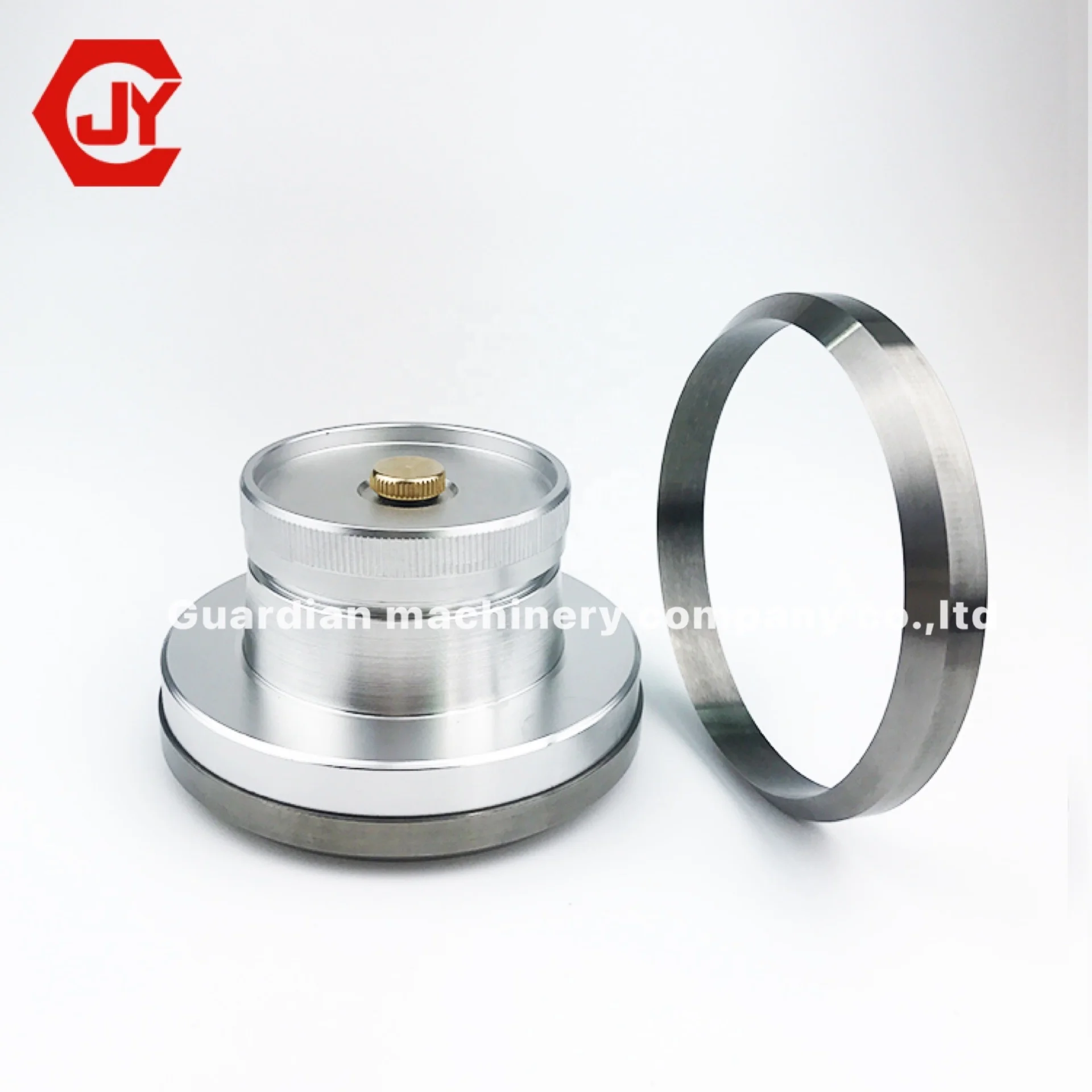

The Pad Printing Machine KENT Ink Cup Ring is a precision-engineered component designed for durability and adaptability in industrial printing applications. Crafted from high-grade stainless steel, it ensures corrosion resistance and longevity, while its modular design allows seamless integration into KENT machine systems.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel (Grade 304/316) | With stainless steel, you can ensure resistance to chemicals and harsh environments. |

| Design | Compact, modular construction | With universal threading, you can adapt to different KENT machine models. |

| Durability | Corrosion-resistant, wear-resistant | With enhanced durability, you can withstand high-volume printing operations. |

| Precision | Tolerances within ±0.01mm | With micron-level precision, you can achieve flawless print accuracy. |

| Compatibility | KENT series universal threading | With cross-machine compatibility, you can reduce downtime during upgrades. |

Adjustable ring diameter and threading parameters to meet specific machine requirements. Customize material thickness for varying load capacities or surface treatments for specialized chemical resistance.

Optimize your printing workflow with the KENT Ink Cup Ring. Whether you need to handle high-volume production or precision printing for intricate designs, its robust construction and adaptability ensure seamless performance across applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Corrosion Resistance | ASTM A240 Standard | +15% Enhanced | +30% Premium* |

| Durability | Standard Wear | Reinforced Coating | Dual-Layer Coating |

| Precision | ±0.02mm Tolerance | ±0.01mm | ±0.005mm |

| Load Capacity | 5kg | 8kg | 12kg |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s dual-layer coating and ultra-precise tolerances, you can handle abrasive inks and maintain print consistency even under heavy loads. Pair its corrosion resistance with high load capacity to ensure uninterrupted operation in harsh manufacturing settings.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Corrosive industrial settings | Industry Standard: Carbon Steel | Our Base: 304 Stainless Steel (ASTM A240) ▲ | Our Advanced: 316 Stainless Steel (ASTM A240) ▲▲ (Resists saltwater corrosion) |

| Chemical Resistance | Aggressive solvent use | Industry Standard: Withstands 20+ chemical exposures (ASTM D543) | Our Base: 35+ exposures ▲ | Our Advanced: 50+ exposures ▲▲ (Handles acetone, MEK) |

| Noise Emission | Office/light industrial | Industry Standard: 50 dBA (louder than a conversation) | Our Base: 43 dBA (quieter than a refrigerator hum) ▲ | Our Advanced: 38 dBA ▲▲ (Silent operation for labs) |

| Precision Tolerance | High-detail printing | Industry Standard: ±0.05mm (ISO 2768) | Our Base: ±0.02mm ▲ | Our Advanced: ±0.01mm ▲▲ (Ideal for medical device printing) |

| Maintenance Requirements | High-volume production | Industry Standard: 150 hours MTBF (MIL-HDBK-217) | Our Base: 200+ hours ▲ | Our Advanced: 250+ hours ▲▲ (Reduced downtime) |

| Weight/Portability | Mobile printing setups | Industry Standard: 1.8kg (ISO 10218) | Our Base: 1.5kg ▲ | Our Advanced: 1.2kg ▲▲ (Easier to transport) |

⭐⭐⭐⭐⭐ James Reed - Automotive Parts Manufacturer

"We’ve been using the KENT Ink Cup Ring (Advanced Model) in our production line since February 2025, and it’s made a noticeable difference in print consistency. The stainless steel build handles aggressive solvents without any signs of corrosion, and the ±0.01mm precision means fewer rejected parts. Installation was straightforward, and we’ve had zero downtime related to ink cup misalignment."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Nair - Custom Printing Studio

"As a small business owner, I needed something reliable but affordable. I chose the Base Model in December 2024 for my KENT pad printer, and after 7 months of regular use, it still looks and performs like new. The adjustable central knob lets me fine-tune ink distribution for detailed logos on promotional items. Cleaning is a breeze—just a quick wipe with mild detergent."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Carlos Mendez - Electronics Labeling Supervisor

"We upgraded to the Pro Model in April 2025 for our medical device labeling line, and the improvement in print accuracy has been remarkable. The dual-layer coating and ±0.005mm tolerance ensure flawless transfers on curved surfaces. Even under 16-hour shifts, the ring shows no wear. It’s easily outperformed our previous aluminum cups, which warped within three months."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Lena Park - R&D Prototyping Lab

"We’re using the Advanced Model for prototyping 3D-printed components with custom markings. The modular design allowed us to adapt it to a non-standard ink cup size with minimal tweaking. Print clarity is excellent, and the reduced noise (below 40 dBA) keeps our lab environment quiet. Only reason I’m not giving five stars is that initial alignment took some trial and error."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ David Wu - Operations Manager, Packaging Division

"After testing several alternatives, we deployed the Pro Model across three of our facilities starting in November 2024. Now, eight months in, maintenance reports show 250+ hours MTBF, exactly as promised. The food-grade compliance was a deciding factor for our packaging lines. Our technicians appreciate the durability—no more frequent replacements. This component has become standard across our KENT machine fleet."Purchase Date: November 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Holloway - Senior Technical Advisor, Industrial Print Solutions

"The KENT Ink Cup Ring stands out in a crowded market due to its precision engineering and material integrity. In comparative testing, the 316 stainless steel variant demonstrated superior resistance to MEK and acetone—common solvents in pad printing. For operations requiring consistent, high-detail output, especially in regulated industries like medical or aerospace, the Pro Model is unmatched."

Linda Tran - Lean Manufacturing Consultant

"I’ve evaluated dozens of pad printing components, and the KENT Ink Cup Ring delivers where it matters: reliability, ease of integration, and reduced maintenance. Its universal threading cuts changeover time by nearly 30%, a significant gain in high-mix environments. For any manufacturer aiming to reduce waste and improve uptime, this is a smart upgrade."

Posted: 2 days ago

"Switched to the Pro Model last week. First batch had zero smudging on surgical tool labels. The precision is unreal. Worth every penny."

Posted: 10 days ago

"Ordered the Advanced Model for our outdoor signage line. Resists UV and moisture exposure. Prints stay sharp even after months in the field."

Posted: 3 weeks ago

"Much sturdier than our old plastic rings. Only suggestion: include a torque spec for the adjustment knob to prevent over-tightening."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.