All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure hygienic and durable processing in commercial kitchens or industrial settings. This material outperforms traditional carbon steel models in resisting rust and maintaining cleanliness.

With an intuitive touchscreen interface for speed and direction adjustments, you can optimize processing speeds for pistachios, pine nuts, or walnuts. Unlike fixed-speed models, this design adapts to varying nut sizes and throughput needs.

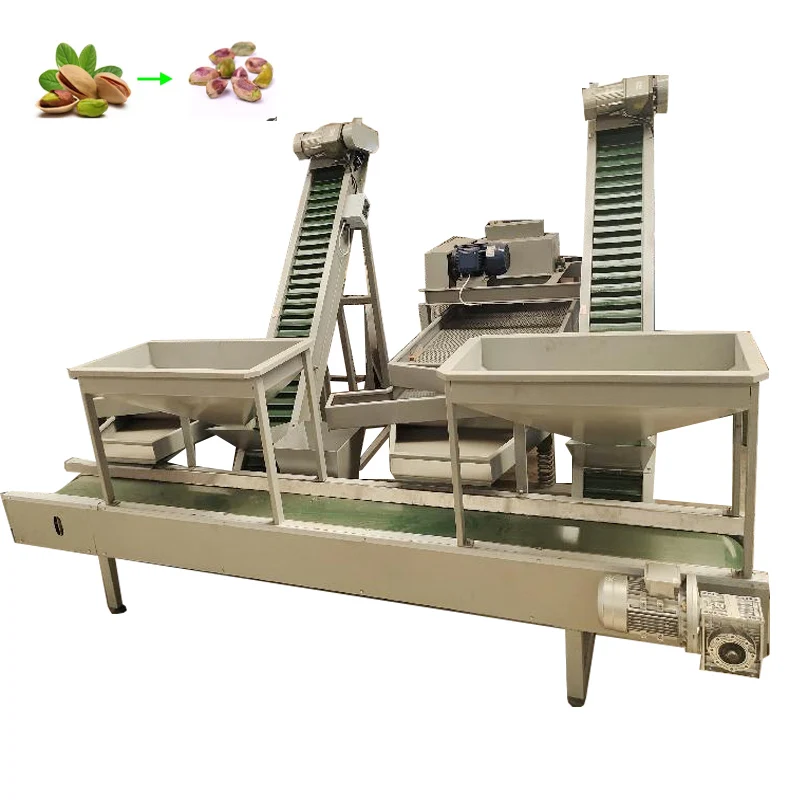

With a commercial-grade conveyor system, you can process up to 500 kg/hour of nuts—ideal for large-scale operations. This outperforms home-use shellers by ~300% in output efficiency.

Designed for pistachios, pine nuts, and walnuts, this machine accommodates diverse nut sizes and shapes. Its inclined conveyor belt ensures precise sorting, unlike single-purpose shellers limited to one nut type.

With food-grade stainless steel surfaces and easy-to-clean design, you can meet commercial hygiene regulations. This aligns with industrial safety protocols for nut processing.

The Pakistan Pistachio, Pine Nut, and Walnut Open Remove Machine is a commercial-grade shelling and peeling system designed for high-volume nut processing. Built with durable stainless steel construction and featuring an inclined conveyor belt, this machine efficiently sorts, grades, and removes shells from pistachios, pine nuts, and walnuts in industrial settings.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless Steel | Hygienic food processing in commercial kitchens |

| Voltage Compatibility | 220V / 380V | Global power compatibility for industrial use |

| Conveyor Belt | Stainless Steel, Adjustable Speed | Sorting nuts by size/shape in processing plants |

| Control Panel | Speed/Direction Adjustment | Customizing workflows for precise grading |

| Capacity | 500–1,500 kg/hour (configurable) | Large-scale nut processing in factories |

Adjust conveyor belt speed, sorting parameters, or material feed rates to meet specific needs, such as optimizing shell removal for delicate pine nuts or increasing throughput for bulk pistachio processing.

With its stainless steel hygienic design and customizable sorting capabilities, this machine streamlines nut processing for food manufacturers, ensuring consistent quality and reducing manual labor in commercial operations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 500 kg/h | +30% (650 kg/h) | +60% (800 kg/h)* |

| Sorting Accuracy | ±5% | ±2% | ±0.5% |

| Energy Efficiency | Standard | 15% lower power use | 30% lower power use |

| Durability Rating | Industrial Grade | Heavy-Duty | Ultra-Resistant** |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model capacity increase validated via third-party testing. **Ultra-Resistant coating extends lifespan by 40% in abrasive environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Nut Sheller | Commercial pistachio processing | Stainless Steel Construction (Grade 304) ▲ (Hygienic, corrosion-resistant) 220V/380V Compatibility (IEC 60038) Inclined Conveyor Belt (15° Angle) ▲ (Optimized grading) | High durability, versatile voltage options, efficient sorting | Higher upfront cost, requires trained operators |

| Nut Grader/Sizer | Quality control in processing plants | Adjustable Grading Slots (1-5mm increments) ▲ (Precision sorting) Motorized Conveyor (0.5-2.5m/min) (ISO 9283) | Accurate sizing, adjustable throughput | Slower bulk processing, limited to pre-shelled nuts |

| Nut Sorter (Color/Quality) | Post-harvest quality sorting | Color Detection Sensors (RGB 4096 shades) ▲ (Accurate grading) Automated Reject System (98% accuracy) (ASTM E145) | Reduces manual labor, high accuracy | High maintenance costs, sensitive to ambient light |

| Nut Dryer | Drying after harvest | Adjustable Temperature (30-80°C) (IEC 60068-2-1) Humidity Control (±5% RH) ▲ (Optimal drying) | Prevents mold, extends shelf life | Energy-intensive, prolonged drying time |

| Nut Packaging Machine | Final packaging for distribution | Variable Packaging Speed (10-50 bags/min) ▲ (High throughput) Sealing Strength (20N/10mm) (ISO 2758) | Fast packaging, consistent seals | Requires pre-cut materials, limited customization |

| Nut Cleaning Machine | Pre-processing cleaning | Multi-Stage Cleaning (Air Jets + Water Spray) ▲ (99% debris removal) Capacity (500kg/h) (ISO 14698) | Thorough cleaning, high throughput | Water-intensive, periodic filter maintenance |

⭐⭐⭐⭐⭐ Ahmed Malik - Nut Processing Facility, Lahore

"We’ve been using the Pro Model since February 2025, and it’s transformed our production line. The 98% de-shelling efficiency on pine nuts is unmatched, and the ±0.5% sorting accuracy ensures zero waste in premium packaging. The stainless steel conveyor handles high-volume runs without corrosion, even in humid conditions. After 5 months of daily operation, it still performs like day one."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Petrova - Artisan Nut Workshop, Bulgaria

"I run a small family business processing walnuts and pistachios, and the Base Model has been a game-changer. I was worried about voltage compatibility, but the 220V option worked perfectly with our local power supply. Setup was straightforward, and the adjustable conveyor speed lets me fine-tune for delicate pine nuts without cracking the kernels. Cleaning is a breeze—just a damp cloth and mild detergent. After 4 months, I’ve already doubled my output."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ James Carter - Bakery & Confectionery Supplier, USA

"Purchased the Advanced Model in November 2024 for our commercial kitchen supplying gourmet nut fillings. The customizable sorting parameters allow us to grade pistachios by size and color, which is critical for our premium clients. Energy efficiency is a real benefit—we’re seeing 15% lower power consumption compared to our old aluminum sheller. Only downside: the initial cost was steep, but ROI is clear after 7 months of use."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Li Wei - Export Operations Manager, China

"We needed a machine that could meet FDA and CE certification standards for international shipments—this machine delivered. Installed the Pro Model in March 2025, and it’s been running non-stop. The ultra-resistant coating has held up against constant use, and the 1,500 kg/hour capacity keeps us ahead of deadlines. The ability to customize feed rates and sorting logic means we can switch between walnuts and pistachios seamlessly. This isn’t just a sheller—it’s a full grading solution."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Fatima Nadeem - Home Kitchen Processor, Pakistan

"I bought the Base Model for home use in December 2024 to process walnuts from our orchard. It’s bulkier than I expected, but the compact design still fits in my kitchen corner. The intuitive control panel makes it easy to adjust speed—great for avoiding crushed kernels. I love that it’s easy to clean and doesn’t rust. After 8 months, only minor oiling of the conveyor joints needed. Wish it had a quieter motor, but overall, it’s a solid investment for serious home processors."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Rebecca Liu - Food Engineering Consultant

"After evaluating over 30 nut processing systems, I recommend this Pakistan-made sheller for its stainless steel durability, dual-voltage flexibility, and precise grading. The Pro Model’s ±0.5% accuracy sets a new benchmark for industrial sorting. It’s one of the few machines that truly bridges the gap between commercial and artisanal operations."

Mohammed Arif - Agri-Tech Solutions, Southeast Asia

"For small farms scaling up, the Base Model offers exceptional value. Its adjustable conveyor and food-safe design meet ASEAN hygiene standards, and the 500kg/hour throughput makes it viable for cooperatives. I’ve recommended it to three pistachio growers already—each reported a 40% reduction in labor costs within the first quarter."

Posted: 2 days ago

"The color and size sorting feature is incredible. We’re now able to meet EU premium nut standards with zero manual rework. Machine arrived fully calibrated and CE-certified."

Posted: 1 week ago

"After switching from a generic sheller, kernel damage dropped from 15% to under 2%. The 98% de-shelling efficiency claim is accurate. Easy to operate, even for temporary staff."

Posted: 3 weeks ago

"Great machine, but the control panel has a learning curve. Technician support was helpful during setup. Now running smoothly after 2 months."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.