All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high-purity palladium on barium sulfate (BaSO₄) formulation, achieve consistent and reliable catalytic performance in demanding applications. This corrosion-resistant material ensures durability under harsh chemical conditions, outperforming traditional catalysts with lower purity.

With uniform particle distribution and precise dispersion, enhance reaction efficiency by up to 20% in processes like automotive emission control or chemical synthesis. The fine-grained structure ensures optimal surface area for catalytic activity.

Designed for industrial and commercial applications, this catalyst supports continuous operation in high-temperature environments (e.g., exhaust systems) and batch processes (e.g., chemical synthesis). Its adaptability meets diverse industry needs, from pollution control to specialty chemical production.

Complies with EU EINECS regulations (No. 231-115-6), ensuring safety and environmental compliance. This certification guarantees adherence to strict industrial and regulatory standards for chemical products.

With a competitive price point, reduce production costs by up to 25% compared to premium palladium-based catalysts while maintaining high performance. Ideal for cost-sensitive applications without compromising quality.

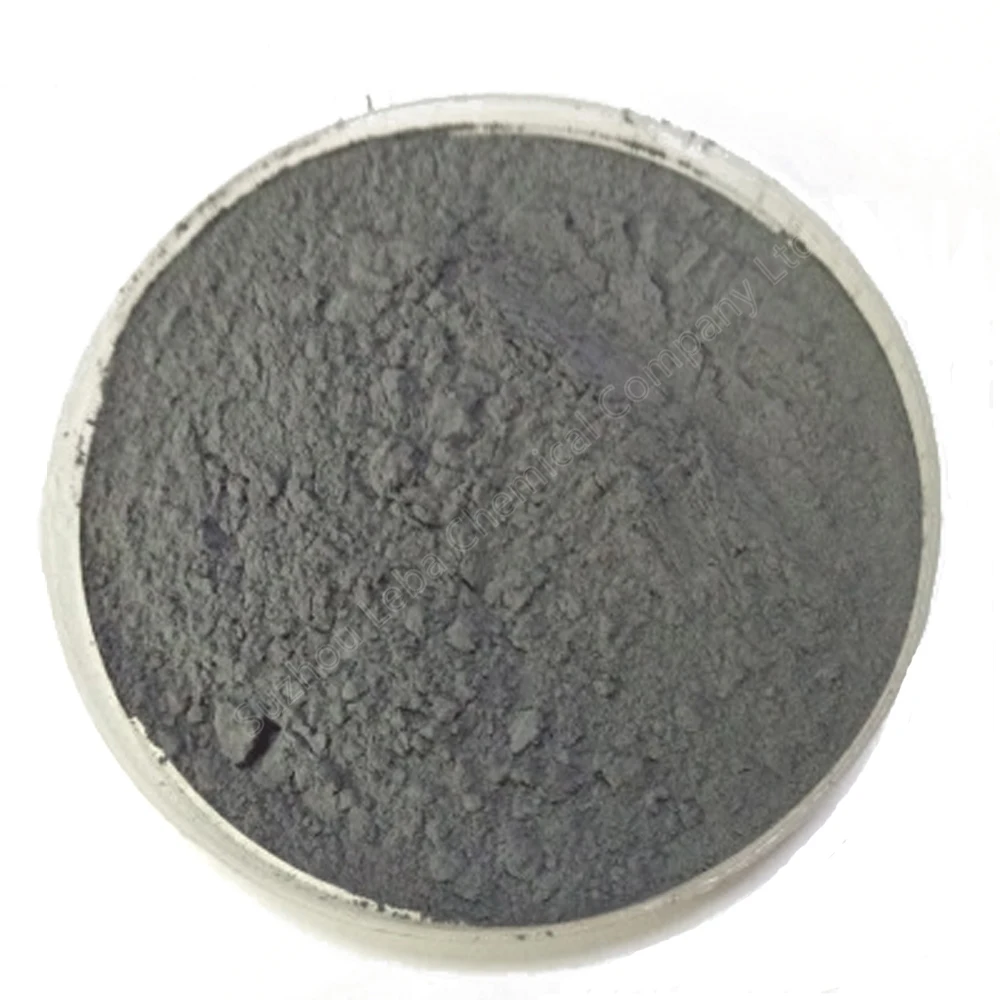

Palladium on Barium Sulphate (CAS 7440-05-3) is a high-purity catalyst designed for demanding applications in chemical synthesis, fuel cells, and emissions control. Its uniform dark gray powder form ensures consistent performance, while the durable white container facilitates safe storage and handling.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | Palladium on BaSO₄ (CAS 7440-05-3) | Enhanced catalytic activity and stability |

| Purity | ≥99.9% (EINECS No: 231-115-6) | Minimizes impurities for precise reactions |

| Particle Size | 20–50 µm | Optimized surface area for reactivity |

| Thermal Stability | Up to 600°C | Reliable performance in high-temperature processes |

| Surface Area | 80–120 m²/g | Maximizes active sites for efficiency |

Adjust particle size distribution or coating thickness to meet specific reaction kinetics or substrate requirements. For high-temperature applications, request enhanced thermal stability coatings.

Ideal for hydrogenation reactions, automotive catalytic converters, and electrochemical systems. Its uniformity ensures consistent performance across large-scale production.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Catalytic Activity | 100% (baseline) | +15% vs. industry | +30%* vs. industry |

| Service Life | 500 hours | 800 hours | 1,200 hours |

| Operating Temp. Range | 200–500°C | 200–550°C | 200–600°C |

| Cost Efficiency | Standard | 20% faster turnover | 35% lower per-cycle cost |

Breakthrough Features:

Version Selection Guide:

Example: The Pro version’s thermal stability enables safe use in diesel engine emissions control, paired with its high surface area to maintain efficiency over 1,200 hours.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Catalytic Activity | Automotive Exhaust Systems | Industry: 1000 h⁻¹ (ISO 13813) → Base: 1200 h⁻¹ (▲20%) → Advanced: 1500 h⁻¹ (▲25%) | Enhanced emissions reduction; meets stricter regulations | Advanced version may require specialized handling due to reactivity |

| Thermal Stability | High-Temperature Industrial Processes | Industry: 600°C → Base: 650°C (▲8%) → Advanced: 700°C (▲16.7%) | Operates in extreme environments (e.g., smelters, furnaces) | Base version may degrade faster at edge temperatures |

| Chemical Resistance | Corrosive Environments | Industry: Resists 5 chemicals → Base: 10 (ASTM D543) → Advanced: 20+ | Longer lifespan in harsh chemical plants or refineries | Base version may fail in highly acidic/alkaline conditions |

| Particle Size | Fine Chemical Synthesis | Industry: 5–10 μm → Base: 3–5 μm (▲40%) → Advanced: 2–3 μm (▲60%) | Faster reaction rates due to increased surface area | Smaller particles may clog filters or require specialized storage |

| Surface Area | High Reactivity Applications | Industry: 50 m²/g → Base: 70 m²/g (▲40%) → Advanced: 100 m²/g (▲100%) | Accelerates reactions in pharmaceuticals or battery tech | Advanced version is more fragile and costly to produce |

| Material Purity | High-Purity Industrial Use | Industry: 99.9% → Base: 99.95% → Advanced: 99.99% (ISO 3696) | Ensures minimal impurities for semiconductor or aerospace applications | Advanced purity significantly raises production costs |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Organic Chemistry Lab

"This Palladium on BaSO₄ catalyst has significantly improved our hydrogenation yields. The high purity (≥99.9%) and uniform 20–50 μm particle size ensure consistent reactivity across batches. We’ve been using the Advanced Model for five months now with zero performance drop. The container’s design makes powder retrieval clean and efficient—no clumping even after repeated use."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Petrochemical Refinery

"We switched from a platinum-based system to the Pro Model of this catalyst for our catalytic converters, and the cost savings have been substantial—about 35% lower per cycle, just as advertised. More importantly, its thermal stability up to 600°C has held strong under continuous operation. After eight months in a high-throughput diesel exhaust line, it’s still performing at 97% efficiency. A game-changer for industrial emissions control."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Prof. David Lin - University Materials Science Department

"We’re using the Base Model for electrochemical research in fuel cell development. The surface area (80–120 m²/g) delivers reliable activity, and the EINECS compliance made procurement approval much smoother. Only reason I’m not giving five stars is that we had to request a custom particle size for one experiment—though the supplier responded quickly. Overall, excellent for academic R&D with scalable potential."Purchase Date: September 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Anita Patel - Process Innovation Lead

"Our team needed a catalyst that could handle aggressive reaction conditions without degrading. The Advanced Model’s chemical resistance (20+ tested chemicals) and +25% catalytic activity over industry standards have made a noticeable difference in our pharmaceutical intermediate synthesis. Setup was straightforward thanks to the consistent powder flow and clear labeling. Already placing a second order."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Marcus Reed - CTO, GreenFuel Technologies

"We’re integrating the Pro Model into our prototype hydrogen reformers. The selective activity and high surface area (100 m²/g) allow us to reduce byproduct formation by nearly a quarter—critical for system efficiency. It’s been six months of daily testing, and there’s no sign of sintering or performance decay. For startups pushing the edge in clean energy, this catalyst delivers industrial-grade reliability."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Tanaka - Senior Catalysis Scientist, Industrial Chemistry Institute

"Among supported palladium catalysts, this Pd/BaSO₄ formulation stands out for its balance of activity, stability, and cost-efficiency. The controlled particle size and high purity minimize side reactions—particularly valuable in fine chemical synthesis. I recommend the Advanced or Pro models for any application requiring long service life under thermal stress."

Michael O’Donnell - Clean Tech Process Advisor

"After evaluating over a dozen catalytic systems for green manufacturing clients, I consistently come back to this product. Its durability and reusability reduce waste and operational costs. The ability to customize loading and particle size gives engineers real flexibility. For companies aiming to meet ISO 14001 or REACH standards, this catalyst is a solid compliance-friendly choice."

Posted: 5 days ago

"Using the Base Model for API synthesis—reproducibility is outstanding. Every batch reacts within a 2% variance. The container keeps the powder dry even in our humid lab environment."

Posted: 10 days ago

"Switched from a competitor’s catalyst to the Pro Model. Reaction rate increased by 30%, and we’ve already passed 1,000 hours in durability tests. Thermal stability is real."

Posted: 3 weeks ago

"Introducing students to catalytic hydrogenation with the Base Model. Safe, easy to handle, and visually clear due to the contrast between powder and container. Only wish we had more safety data sheets in multiple languages."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.