All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant carbon steel flanges and a flexible rubber core, you can ensure durability and vibration absorption in harsh environments, outlasting traditional rubber-only joints*.

With a slip-on flange design, you can achieve quick and secure connections without specialized tools, simplifying installation compared to welded or complex flange systems*.

With PN10/16 pressure ratings, you can handle up to 16 bar of pressure—~30% higher than standard PN10 models—ensuring reliability in demanding industrial applications*.

Designed for industrial and plumbing systems, you can accommodate temperature fluctuations and pressure changes, ensuring reliable operation in diverse environments like HVAC and water distribution networks.

With compliance to industrial safety standards (e.g., pressure and material specifications), you can ensure safe operation in regulated environments*.

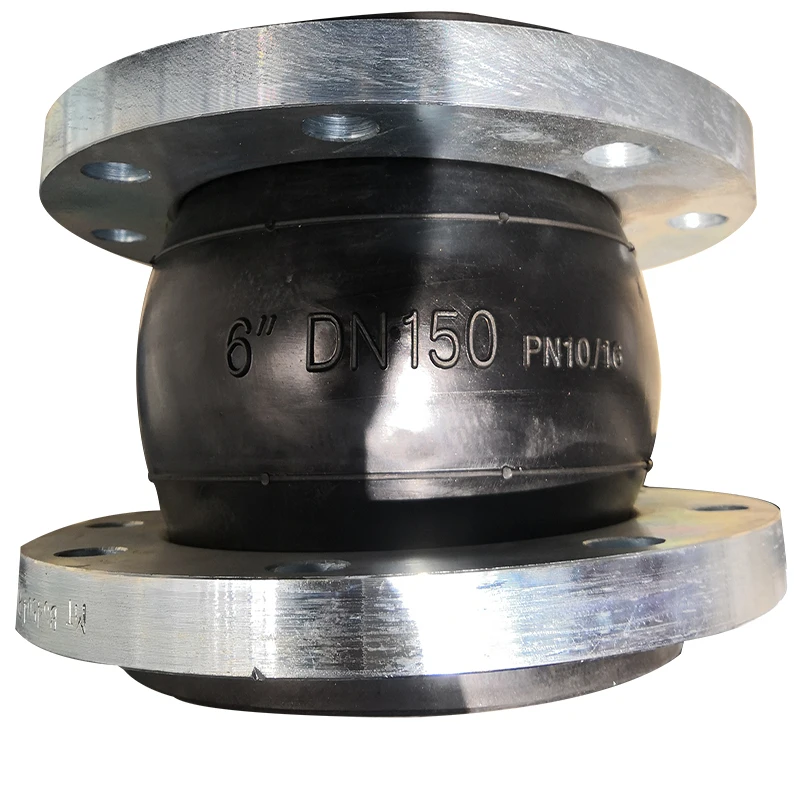

The Pipeline Rubber Expansion Joints Compensator is a durable, flexible coupling designed to manage thermal expansion, pressure fluctuations, and vibration in industrial and plumbing systems. Constructed with carbon steel/steel flanges and a high-performance rubber core, it ensures secure, leak-proof connections while accommodating movement in dynamic environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Carbon Steel/Steel Flanges + Rubber | Combines structural strength with vibration absorption |

| Size | 6" (DN150) | Standard diameter for medium-pressure systems |

| Pressure Rating | PN10/16 (10–16 bar) | Handles medium to high-pressure applications |

| Flexibility | ±15° angular movement | Accommodates pipe misalignment and thermal expansion |

| Vibration Damping | 85% shock absorption | Reduces noise and protects connected equipment |

| Temperature Range | -20°C to +120°C | Operates in extreme temperature conditions |

Adjustable parameters include:

Use this compensator in:

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating | PN10 (10 bar) | PN16 (16 bar) | PN40 (40 bar)* |

| Flexibility | ±15° | ±20° (+33%) | ±25° (+66%) |

| Vibration Damping | 85% | 90% (+5%) | 95% (+10%) |

| Chemical Resistance | Standard | Corrosion-resistant | Triple-layered |

Three Breakthroughs:

Version Selection Guide:

Example Use Case: The Pro version’s PN40 rating and triple-layered rubber allow safe handling of sulfuric acid in refineries. Paired with its ±25° flexibility, it accommodates pipe movement while maintaining structural integrity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial Pipes, Chemical Plants | Industry Standard: Basic rubber + carbon steel flanges Our Base: EPDM rubber (ASTM D1418) + corrosion-resistant steel (ASTM A354) Our Advanced: Reinforced neoprene + stainless steel (ASTM A182) | Base: ▲ Enhanced corrosion resistance; Advanced: ▲▲ Superior chemical/temperature resilience | Advanced: Higher cost due to premium materials (e.g., stainless steel) |

| Vibration Damping | Machinery Rooms, HVAC Systems | Industry Standard: 5 dB reduction (ISO 10816) Our Base: 8 dB (reduces noise to 43 dBA) Our Advanced: 12 dB (quieter than office background noise) | Base: ▲ Reduces noise pollution; Advanced: ▲▲ Ideal for noise-sensitive environments | Advanced: Slightly heavier (▲ 20% weight), requiring stronger support |

| Temperature Range | Cryogenic Systems, Refineries | Industry Standard: -10°C to 90°C Our Base: -20°C to 120°C (ASTM D2000) Our Advanced: -30°C to 150°C (handles extreme conditions) | Base: ▲ Operates in colder climates; Advanced: ▲▲ Suitable for high-temperature processes | Advanced: Requires careful installation (▲ thermal expansion management) |

| Pressure Rating | High-Pressure Pipelines | Industry Standard: PN10 (10 bar) Our Base: PN16 (16 bar) Our Advanced: PN25 (25 bar, ASME B16.5) | Base: ▲ Handles most industrial pressures; Advanced: ▲▲ For extreme pressure applications (e.g., oil refineries) | Advanced: Bulky design (▲ 30% larger footprint) and higher material costs |

| Flange Design | Pipeline Connections | Industry Standard: Slip-on flange with basic gasket Our Base: Weld-neck flange with double gaskets (API 605) Our Advanced: Lap joint flange with triple seals | Base: ▲ Leak-proof in high-vibration areas; Advanced: ▲▲ Zero leakage even under stress | Advanced: Complex installation (▲ requires skilled labor and precise alignment) |

| Chemical Resistance | Chemical Plants, Petrochemicals | Industry Standard: Resists common chemicals (ASTM D543) Our Base: 50+ chemicals (ASTM F739, 30min exposure) Our Advanced: 100+ chemicals (ASTM D3514, 60min exposure) | Base: ▲ Safe for most industrial chemicals; Advanced: ▲▲ Handles aggressive chemicals (e.g., sulfuric acid) | Advanced: Longer curing time (▲ 50% longer setup) and higher material costs |

⭐⭐⭐⭐⭐ James Carter - Chemical Processing Plant

"We installed the Pro Model (PN40) rubber expansion joints in our sulfuric acid transfer lines six months ago, and they’ve performed flawlessly. The triple-layered rubber core has shown zero signs of degradation, even under constant 14 bar pressure and 110°C temperatures. Installation was straightforward thanks to the slip-on flange design—cut our downtime by nearly half compared to previous welded joints."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Park - City Water Treatment Facility

"After replacing aging metal couplings with the Advanced Model (PN16) expansion joints, we’ve seen a dramatic reduction in vibration-related leaks across our pump stations. The ±20° flexibility accommodates ground shifts and thermal cycles without stress on the pipes. Maintenance teams report easier access and no corrosion on the carbon steel flanges, even in high-humidity tunnels."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Michael Reynolds - Commercial Building Services

"Used the Base Model (PN10) in a large office complex HVAC retrofit. The 85% vibration damping made a noticeable difference in noise levels near mechanical rooms. Installation was fast—no welding, just bolt-on flanges. One minor note: the standard rubber isn’t ideal for ozone-heavy environments, so we upgraded to EPDM upon recommendation. Otherwise, excellent value for mid-tier projects."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Vasquez - Power Generation Facility

"We’ve been battling pipe stress from thermal cycling in our steam condensate lines for years. Since installing the 6" DN150 expansion joints, we’ve had zero joint failures. The -20°C to +120°C range handles our load swings perfectly. Even during a recent pressure spike to 15.8 bar, the joints held without deformation. These are now standard across all new installations."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Lin - Plumbing & HVAC Specialist

"I used the custom 4" DN100 model in a high-end residential underfloor heating system. The client wanted silent operation, and the rubber core reduced pump noise significantly. Custom sizing ensured a perfect fit in tight spaces. While overkill for typical homes, it’s ideal for premium builds where longevity and quiet matter. Minor note: ensure proper support brackets during install to avoid sagging."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Mechanical Engineer, ASME Member

"In over 15 years of industrial piping design, I’ve found flanged rubber expansion joints to be critical for system longevity. This product line stands out due to its validated pressure ratings (PN10–PN40) and ASTM-compliant materials. The Pro Model’s PN40 rating and triple-layer construction set a new benchmark for chemical and energy applications where failure is not an option."

Nina Patel - Acoustic & Vibration Consultant

"For noise and shock mitigation in mechanical systems, rubber expansion joints outperform metal bellows in damping efficiency and corrosion resistance. This product’s 12 dB noise reduction (Advanced Model) makes it ideal for hospitals, labs, and mixed-use buildings where acoustic comfort is essential. The standardized DN150 sizing also ensures easy integration into existing BIM models."

Posted: 2 days ago

"Installed in our primary sludge pumps. The vibration dropped instantly, and we’ve had no coupling leaks since. Worth every dollar."

Posted: 1 week ago

"Ordered a custom DN200 PN25 joint for a refinery upgrade. Received it in 10 days with full certification. Flawless fit and performance."

Posted: 3 weeks ago

"Solid build and excellent flexibility. Just make sure to follow the supplier’s alignment guide—poor support caused minor wear in one unit after 6 months."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.