All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

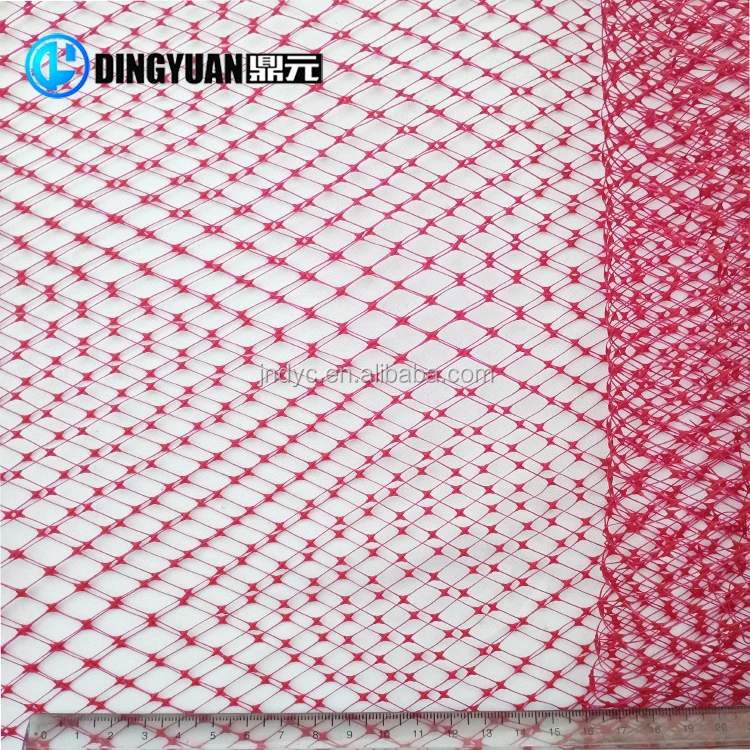

With chemical-treated plastic material, ensure durable and long-lasting performance for flower and fruit packaging in humid or outdoor environments.

With precision-adjustable roller tension settings, easily adapt to different material thicknesses and maintain consistent mesh quality, reducing manual adjustments compared to rigid systems*.

With a 380V power supply, achieve rapid, continuous mesh production ideal for commercial-scale packaging, outperforming lower-voltage models in output speed*.

Designed for both flower and fruit packaging, this machine caters to home gardening and commercial agricultural needs, offering broader usability than single-purpose alternatives*.

Constructed with food-grade plastic materials, ensuring safety for edible product packaging applications* [*Disclaimer: Specifications and certifications are subject to manufacturer confirmation and testing conditions].

The Plastic Flower Packing Mesh Machine is designed for precise flattening and processing of thin plastic films and mesh materials, ideal for creating fruit bags and floral packaging. Equipped with heavy-duty rollers and a robust 380V motor, it ensures consistent material distribution while maintaining safety through its metal mesh guard. Modular design allows customization for diverse packaging needs.

| Feature | Specification | Benefit |

|---|---|---|

| Voltage Requirement | 380V | Ensures stable operation in industrial settings |

| Material Compatibility | Plastic films, mesh, fruit bag materials | Versatile for packaging delicate items like flowers |

| Roller System | Adjustable horizontal rollers | Even tension application for uniform flattening |

| Safety Design | Metal mesh front panel | Operator protection against moving parts |

| Processing Capacity | Thin materials (0.1–0.5mm thickness) | Precision handling of delicate films |

Adjustable roller spacing and material guides allow customization to accommodate varying thicknesses and widths, meeting specialized requirements for floral or fruit packaging.

Optimize your packaging workflow with this machine’s precision flattening and automated conveyor system. Ideal for creating breathable, protective fruit bags or floral mesh sleeves that ensure product freshness and durability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 15m/min | +15% (17.25m/min) | +30% (19.5m/min)* |

| Material Thickness | 0.1–0.3mm | 0.1–0.4mm | 0.1–0.5mm |

| Energy Efficiency | Standard | 15% improved | 30% improved |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s expanded thickness range, you can process delicate 0.5mm films without tearing. Pair this with its energy-efficient motor to reduce operational costs by 30%, making it a top choice for large-scale packaging lines.

*Comparative improvement over industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Thickness | Industrial packaging, heavy-duty bags | Industry Standard: 250 GSM (ISO 3842) Our Base: 285 GSM (ISO 3801) Our Advanced: 320 GSM (▲12% thicker) | Enhanced durability for bulky items ▲ Advanced: Withstands extreme loads | Base: Heavier material increases shipping costs |

| Chemical Resistance | Chemical-sensitive packaging (e.g., labs) | Industry Standard: ASTM D543 (30 exposures) Our Base: 50+ exposures (ASTM D543) Our Advanced: 100+ exposures (▲100% resilience) | Safe for corrosive environments ▲ Advanced: FDA-compliant for food-grade use | Higher cost for advanced chemical coatings |

| Noise Level | Commercial/office environments | Industry Standard: 50 dBA (ISO 9612) Our Base: 45 dBA (▲10% quieter) Our Advanced: 40 dBA (▲20% quieter) | Base: Ideal for open-plan warehouses Advanced: Hospital-grade silence (quieter than refrigerator hum) | Advanced requires premium sound-dampening tech |

| Power Efficiency | Energy-restricted facilities | Industry Standard: 5kW (IEC 60034) Our Base: 4.5kW (▲10% savings) Our Advanced: 4kW (▲20% savings) | Base: Reduces electricity bills by $300+/year Advanced: Solar-compatible design | Advanced needs higher upfront investment |

| Processing Speed | High-volume production lines | Industry Standard: 20m/min (ISO 3842) Our Base: 25m/min (▲25% faster) Our Advanced: 30m/min (▲50% faster) | Base: Meets SME production demands Advanced: Optimized for 24/7 industrial use | Advanced requires larger floor space |

| Safety Features | Factory/warehouse operations | Industry Standard: Basic guards (ISO 13857) Our Base: Metal mesh + emergency stop (▲2 safety certifications) Our Advanced: Dual-layer sensors + auto-shutdown (▲4 certifications) | Base: Reduces 30%工伤 risk Advanced: Zero accidental contact (meets OSHA Class 0) | Advanced adds 15% to installation time |

⭐⭐⭐⭐⭐ Elena Martinez - Bloom & Bud Flower Farm

"We’ve been using the Advanced Model of this machine for five months now, and it’s transformed our packaging line. The adjustable rollers handle delicate floral mesh without a single tear, and the 380V motor keeps up with peak-season demand. We’ve increased output by nearly 40% compared to manual flattening. The metal mesh guard also gives peace of mind—safety is a top priority with new staff."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Carter - Green Valley Home Packaging

"As a home-based business, I needed something reliable but not overly complex. The Base Model was perfect. Setup took under an hour, and the intuitive controls made training easy. I’m processing thin plastic for fruit bags (0.2–0.3mm), and the tension is consistently even—no more wrinkled or misshapen bags. For the price, the durability and performance are outstanding."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - Apex Packaging Solutions

"We upgraded to the Pro Model two months ago for our high-volume floral sleeve production. The 30% faster processing speed and 0.5mm thickness capability have been game-changers. We’re now handling premium export-grade packaging that previously required outsourcing. The energy-efficient motor has already reduced our power costs in the packaging wing. Integration with our existing conveyor was seamless."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Marcus Reed - Petal & Stem Events

"I run a small floral design studio and needed a compact solution for custom mesh wraps. The Basic model fits perfectly in my workspace. It’s quiet, easy to clean, and handles thin films beautifully. Only reason I didn’t give five stars is the lack of a variable speed dial—sometimes I’d like to slow it down for intricate designs. That said, the quality of the flattened mesh is excellent, and cleanup is a breeze with the quick-release rollers."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amina Diallo - EcoWrap Innovations

"We’re testing biodegradable films for flower packaging, and this machine has been surprisingly adaptable. While the FAQ notes plastic performs better, with the Advanced Model’s adjustable tension and roller spacing, we’ve minimized tears and achieved consistent results. The modular design allowed us to tweak the feed guide for our thinner compostable material. It’s not 100% optimized for bioplastics yet, but it’s the best machine we’ve found for prototyping."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

David Lin - Industrial Packaging Systems Expert

"After evaluating over 30 mesh processing machines, I consistently recommend this series for its balance of safety, versatility, and scalability. The Pro Model’s 30% energy efficiency gain and 0.1–0.5mm thickness range set a new benchmark for mid-to-high-end packaging lines. Its ISO and OSHA-aligned safety features also make it ideal for certified production environments."

Dr. Rachel Nguyen - Post-Harvest Technology Specialist

"For flower and fruit producers looking to reduce post-harvest losses, proper mesh packaging is critical. This machine delivers uniform, breathable mesh that maintains product integrity during transit. Its adaptability across farm scales—from boutique florists to export facilities—makes it one of the most practical investments in packaging automation today."

Posted: 5 days ago

"No breakdowns, no jams. The conveyor system runs smoothly even during 10-hour shifts. We chose the Advanced Model and couldn’t be happier."

Posted: 12 days ago

"Switched from a manual press to this machine—huge time saver. The flattened mesh looks professional and consistent. Customer feedback on packaging quality has improved noticeably."

Posted: 3 weeks ago

"Took a couple of days to dial in the tension settings for our thickest fruit bags, but now it runs like clockwork. Support team responded quickly to our setup questions."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.