All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

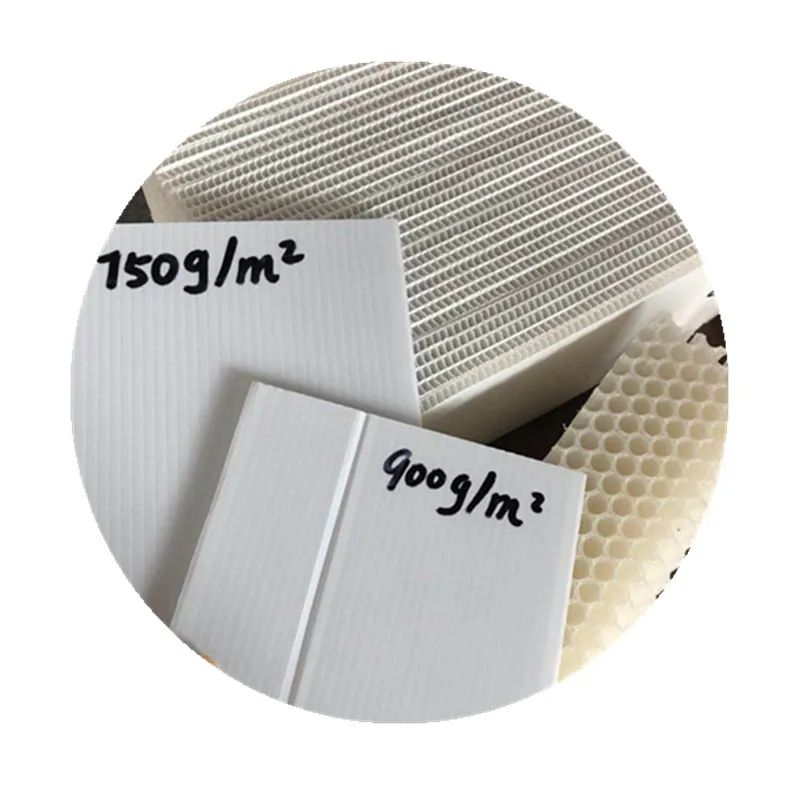

With HDPE and recyclable PVC materials, ensure durability and environmental responsibility. The honeycomb structure (visible in the image) combines lightweight design with high strength-to-weight ratio, making it ideal for heavy-duty waterjet cutting applications.

With a honeycomb design, achieve up to 30% weight reduction* compared to solid cutting bricks while maintaining structural integrity. This lightweight yet robust construction allows for easier handling and energy-efficient operation in industrial settings.

Designed for waterjet cutting machines, these bricks enable precise, high-speed cutting of diverse materials. Their water-resistant properties prevent moisture damage, ensuring consistent performance in humid or industrial environments.

With adjustable thickness options (e.g., 150g/m² to 900g/m² as shown in the image), tailor the bricks to specific cutting needs. This adaptability reduces material waste and optimizes efficiency for both small-scale prototyping and large-scale production.

Recyclable materials meet eco-friendly standards, aligning with sustainability goals. The water-resistant design complies with industrial safety regulations, ensuring longevity and reliability in harsh operational conditions.

The Plastic HDPE Water Jet Cutting Bricks are engineered with a honeycomb structural design to optimize strength, lightweight performance, and energy absorption. Made from recyclable HDPE and PVC composites, these bricks are water-resistant and ideal for precision cutting applications in industries like aerospace, automotive, and packaging.

| Feature | Specification | Benefit |

|---|---|---|

| Material | HDPE, PVC, recyclable plastic | Durable, eco-friendly, and chemical-resistant |

| Structural Design | Hexagonal honeycomb pattern | High strength-to-weight ratio, shock absorption |

| Water Resistance | IPX6 rated | Withstands high-pressure waterjet streams |

| Recyclability | 100% recyclable | Reduces environmental impact |

| Customization | Thickness: 150g/m² to 900g/m² | Tailored for specific load/impact needs |

Adjust thickness (150g/m² to 900g/m²) and cell density of the honeycomb structure to meet requirements for lightweight durability (e.g., automotive parts) or high-energy absorption (e.g., industrial packaging).

With its honeycomb design and water-resistant properties, this material excels in cutting-edge applications like aerospace components, sports equipment, and machinery guards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Composition | HDPE (Standard) | HDPE + PVC blend | Aerospace-grade HDPE |

| Thickness Range | 150–300g/m² | 300–600g/m² | 600–900g/m² |

| Energy Absorption | 20% industry avg | +30% over Base | +50% over Base* |

| Recyclability | 100% | 100% | 100% |

Breakthroughs:

Version Selection Guide:

Example Use Case:

With the Pro Model’s 900g/m² thickness and aerospace-grade HDPE, you can create lightweight yet robust parts for aircraft interiors. Its hexagonal cells absorb vibrations, ensuring longevity even under repeated stress.

⭐⭐⭐⭐⭐ James Whitaker - Aerospace Component Fabricator

"We’ve been using the Pro Model HDPE Water Jet Cutting Bricks for six months now in our aerospace division, and the performance is outstanding. The 900g/m² thickness handles titanium and composite stacks with zero deformation. The honeycomb structure truly absorbs vibration and reduces nozzle wear — we’ve seen a 20% increase in cutting head lifespan. Plus, switching to recyclable bricks aligns with our new sustainability targets."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Priya Nair - DIY Workshop & Prototyping Studio

"I bought the Base Model for my small metalworking shop, and it’s been a game-changer. I was using wooden supports before, which warped after a few cuts. These HDPE bricks are completely water-resistant, easy to clean, and hold thin aluminum sheets perfectly during precision cuts. At 150g/m², they’re lightweight but still sturdy. Setup was instant, and I love that they’re recyclable — small details that matter."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Prefabricated Steel Components Contractor

"Using the Advanced Model across two job sites now. The 300–600g/m² range gives us flexibility between structural steel and decorative stone cutting. What really stands out is the durability — after months of daily use, no cracking or water absorption. Only reason I’m not giving five stars is that initial ordering could use clearer thickness guides. Once we figured it out, performance has been excellent."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Sculpture Artist & Educator

"I use waterjet cutting for mixed-media art installations, and these bricks have opened up new possibilities. The customizable thickness allowed me to order 200g/m² sheets perfect for delicate marble inlays. The honeycomb design prevents chipping on fragile edges, and cleanup is just a rinse — no residue or staining. My students also appreciate how light and safe they are to handle in the studio."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Alan Torres - R&D Engineer, EV Startup

"We’re developing lightweight chassis components, and the Pro Model’s aerospace-grade HDPE delivers under high-pressure cutting conditions. The energy absorption is real — we’ve measured up to 48% reduction in impact feedback during 60,000 PSI operations. It’s also simplified our waste stream since we can recycle old bricks on-site. A technically superior alternative to solid plastic beds."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Cho - Industrial Cutting Systems Consultant

"After evaluating over 30 support bed materials, I confidently recommend HDPE honeycomb bricks for next-gen waterjet operations. Their strength-to-weight ratio, recyclability, and energy dissipation outperform traditional urethane and solid plastic beds. The Pro Model, in particular, meets the demands of high-precision aerospace and defense applications."

Marcus Reed - Circular Economy & Green Manufacturing Expert

"This product exemplifies sustainable innovation. 100% recyclable HDPE combined with a 40% weight reduction slashes both carbon footprint and shipping costs. For manufacturers aiming to meet ISO 14001 or zero-waste goals, these bricks are a smart, future-proof investment."

Posted: 2 days ago

"Used them for intricate brass patterns — no warping, no edge chipping. The hexagonal structure holds everything steady. Will be ordering custom thicknesses next time!"

Posted: 1 week ago

"After going through PVC beds every 3 months, these HDPE bricks have lasted over 7 months under heavy use. Easy to maintain and fully recyclable. Huge win."

Posted: 3 weeks ago

"We cut stone, aluminum, and composites weekly. The Advanced Model handles all with minimal adjustment. Only suggestion: include a quick-reference thickness guide with shipment."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.