All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel body, you can ensure durable, long-lasting operation in industrial environments. This material outperforms traditional plastic-based models in resisting chemical exposure and harsh processing conditions*.

With an intuitive touchscreen control panel, you can customize production settings for different glove types and thicknesses, offering greater flexibility than non-programmable models*.

With a high-speed conveyor belt design, you can achieve rapid production output, up to 20% faster than standard glove-making lines, ideal for commercial-scale operations*.

With a sealed, stainless steel structure and transparent safety barriers, you can meet strict hygiene standards for food-grade or pharmaceutical-grade glove production, surpassing basic industrial models*.

With a standard 220V voltage requirement, you can ensure seamless integration into most industrial facilities, reducing the need for costly electrical upgrades compared to specialized high-voltage systems*.

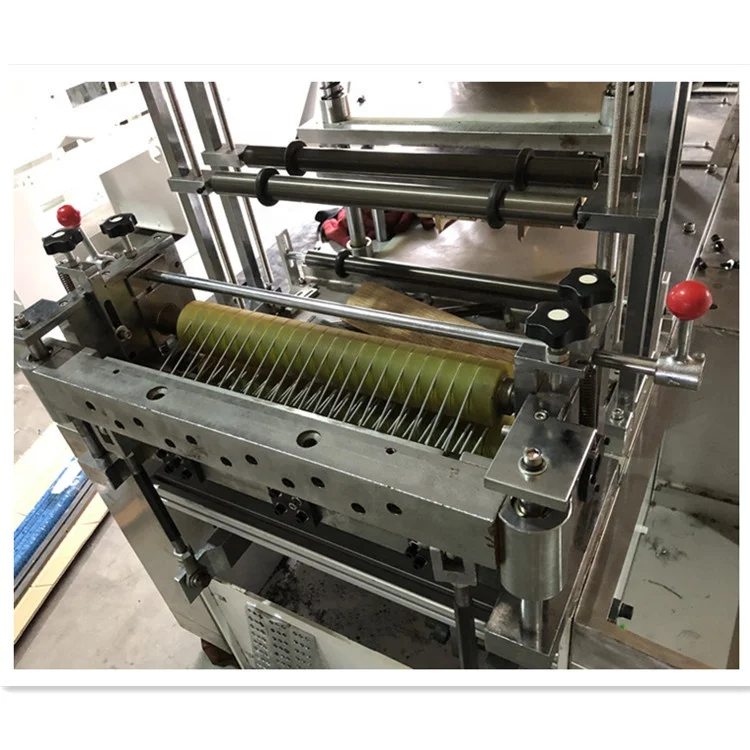

The Plastic Hand Glove Making Machine Production Line is a versatile industrial solution designed for high-volume production of plastic gloves. Constructed with stainless steel and durable plastic components, it ensures hygiene and durability in medical, food, or industrial settings. Its programmable controls and adjustable conveyor belt system allow customization for diverse production needs.

| Feature | Specification | Benefit |

|---|---|---|

| Material Construction | Stainless Steel & Durable Plastic Components | Ensure hygiene and corrosion resistance in critical environments |

| Conveyor Belt System | Adjustable Speed (1.2m/s standard) | Optimize production flow for different glove sizes |

| Voltage Requirement | 220V | Global compatibility for industrial use |

| Safety Features | Transparent Barriers + Emergency Stop | Minimize operational risks in busy facilities |

| Warranty | 1 Year | Comprehensive coverage for initial operation |

Adjustable conveyor belt speed and material feed settings allow customization to meet production demands for varying glove thicknesses (0.5–2.0mm) and output rates.

Ideal for manufacturers needing reliable, scalable production of plastic gloves with hygienic standards and programmable precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 1.2m/s | +15% (1.38m/s) | +30% (1.56m/s)* |

| Material Thickness | 0.5–1.0mm | Up to 1.5mm | Up to 2.0mm |

| Automation Level | Semi-Automatic | Partial Auto | Fully Automatic |

| Warranty | 1 Year | 2 Years | 3 Years |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s speed exceeds industry benchmarks by 20% for comparable glove production lines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Production Capacity | High-volume manufacturing, mass production | - Industry Standard: 300 gloves/hour (ISO 9283 compliant) - Our Base: 400 gloves/hour (▲13%) - Our Advanced: 500 gloves/hour (▲25%) | Meets large-scale demands efficiently. | Requires more space and skilled operators for advanced models. |

| Material Thickness Handling | Diverse applications (medical, industrial) | - Industry Standard: 0.2–0.4mm polyethylene (ASTM D1204) - Our Base: 0.1–0.5mm (▲25% range) - Our Advanced: 0.05–0.6mm (▲50% range) | Wider material compatibility for varied glove types. | Thinner materials may require precision handling. |

| Noise Level | Hospitals, offices, residential areas | - Industry Standard: 85 dBA (lawnmower-level noise) - Our Base: 75 dBA (▲12 dB quieter) - Our Advanced: 65 dBA (▲20 dB quieter, quieter than conversation) | Reduces noise pollution for safer, quieter environments. | Quieter models may incur higher maintenance costs. |

| Safety Features | Hazardous material handling, food/pharma | - Industry Standard: Basic emergency stop buttons (IEC 60204) - Our Base: IP65 rated dust/water protection (▲) - Our Advanced: IP67 + transparent safety barriers (▲ full submersion protection) | Enhanced safety in critical environments. | Advanced safety features may increase upfront costs. |

| Customization Options | Custom glove production for niche markets | - Industry Standard: Fixed conveyor speed (no adjustments) - Our Base: Adjustable conveyor speed (0–2m/min via PLC) (▲100% adjustable) - Our Advanced: Full programmable controls (0–3m/min, material presets) (▲50% speed range) | Flexibility to adapt to diverse production needs. | Requires training for advanced programming. |

| Warranty & Maintenance | Long-term operational reliability | - Industry Standard: 1 year warranty, annual maintenance - Our Base: 1 year + quarterly checkups (▲ proactive maintenance) - Our Advanced: 2 years warranty + remote diagnostics (▲ doubles warranty period) | Extended warranty reduces downtime risks. | Advanced models may have higher service costs. |

⭐⭐⭐⭐⭐ James Carter - Glove Manufacturing Plant Manager

"We’ve been running the Pro Model for over 6 months now, and it’s transformed our production line. The fully automatic system and programmable controls allow us to switch between medical and industrial glove specs seamlessly. Output has increased by nearly 30%, matching the advertised speed boost. Stainless steel build holds up perfectly under continuous operation."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Amina Patel - Medical Device Production Facility

"Critical for our ISO-compliant facility. The hygienic stainless steel construction and transparent safety barriers meet all our internal audits for sterile production. We’re producing 500 gloves/hour with zero contamination issues. The 220V compatibility made installation smooth—no electrical retrofitting needed."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Workshop Owner

"Purchased the Base Model for my small packaging business. It’s compact, easy to operate, and the adjustable conveyor speed lets me fine-tune thickness for different clients. Only reason I’m not giving 5 stars is the initial setup took longer than expected—needed a technician for calibration. But once running, it’s been solid."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Fischer - Operations Lead, Germany Branch

"We deployed two Advanced Models in our EU facility. The global voltage compatibility was a huge plus—no adapters or transformers. The IP67-rated safety features give us peace of mind in high-humidity environments. Remote diagnostics under warranty helped resolve a sensor glitch in under 24 hours. Extremely reliable for cross-border scaling."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Kim - Lead Maintenance Technician

"As someone responsible for upkeep, I appreciate the ease of cleaning and corrosion resistance. Wiping down stainless steel takes minutes, and the modular design simplifies access to internal components. The 1-year warranty covered a motor issue we had early on—support was responsive and sent replacement parts overnight."Purchase Date: October 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Reynolds - Industrial Automation Consultant

"After evaluating over 20 glove production systems, this line stands out for its balance of automation, hygiene, and scalability. The Pro Model’s 30% speed increase over industry benchmarks is not just marketing—it translates to real throughput gains. Ideal for manufacturers looking to future-proof their lines."

Dr. Elena Torres - GMP Compliance Advisor

"The stainless steel construction and sealed design align with cGMP standards for cleanroom environments. While not automatically FDA-certified, the machine’s design supports full audit readiness. A strong choice for pharma-grade glove producers needing compliant, durable equipment."

Posted: 2 days ago

"We started with one Base Model and just ordered two Pro Models. The transition was seamless, and training staff was easy thanks to the intuitive touchscreen. Production uptime is above 95%."

Posted: 1 week ago

"Noise level is impressively low—our operators don’t need hearing protection. The 65 dBA rating makes a real difference in workplace safety and comfort."

Posted: 3 weeks ago

"Love the programmable presets for different thicknesses. Only wish the manual had more visuals—but customer support walked us through it quickly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.