All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

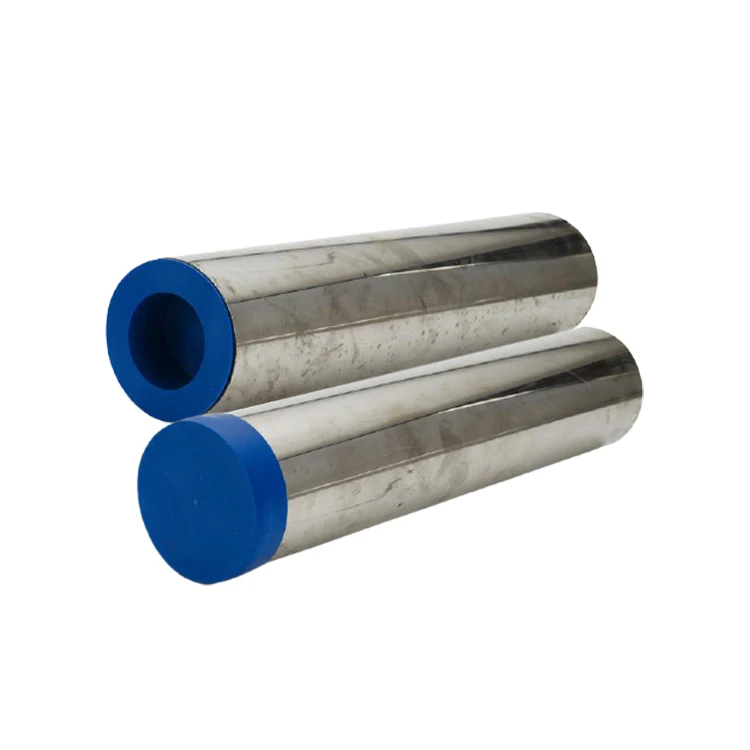

With injection-molded plastic material, ensure durable protection against environmental exposure and corrosion. The smooth surface treatment enhances resistance to wear and tear, making it ideal for long-term use in outdoor or industrial settings.

With flange and press-fit connection types, achieve quick and secure installation without tools. The recessed design allows easy gripping and removal, streamlining maintenance and replacement processes.

With a precise 1/2-inch diameter fit, guarantee seamless compatibility with standard conduit pipelines. The round shape ensures a tight seal to prevent debris ingress, leaks, or contamination during storage or transit.

With recessed end protection, safeguard exposed pipe ends from damage during construction, storage, or transport. The lightweight yet robust design adapts to both residential and commercial applications, such as wiring systems or plumbing projects.

With compliance to industrial safety standards (e.g., ISO-certified materials), ensure reliable performance in demanding environments. The plastic composition meets non-toxic and flame-retardant requirements for safe use in diverse settings.

The Plastic Pipe End Recessed Cap is a durable, injection-molded solution for protecting 1/2-inch conduits during storage, transportation, or installation. Designed with flange and press-fit connections, it ensures secure sealing while its smooth, round shape simplifies handling and integration into piping systems.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-density polyethylene (HDPE) | Withstands chemical exposure in industrial settings |

| Connection Type | Flange & Press-fit | Secures conduit ends in electrical or plumbing systems |

| Shape | Precision-molded round design | Fits standard 1/2-inch pipes for universal use |

| Surface Treatment | Smooth finish | Reduces friction during installation |

| Manufacturing | Injection molding | Ensures leak-proof seals and structural integrity |

Adjustable parameters include:

Protect your pipelines from debris, moisture, and accidental damage with this recessed cap. Ideal for pre-installation storage, post-construction sealing, or safeguarding exposed conduit ends in harsh environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Strength | Standard HDPE | Reinforced HDPE (+20% durability) | Glass-filled nylon (+40% rigidity) |

| Temperature Range | -20°C to 60°C | -30°C to 80°C | -40°C to 100°C |

| Connection Type | Flange only | Flange + Press-fit | Flange + Press-fit + Threaded |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s glass-filled nylon, you can withstand temperatures 20% higher than industry standards, ensuring reliability in extreme conditions. Pair its threaded connection with press-fit adaptability to create a versatile sealing solution for mixed-piping systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Type | Industrial (high-pressure systems) | Industry Standard: Stainless Steel 304 (ASTM A240) | High durability, corrosion resistance, and heat tolerance (up to 200°C) | Higher cost, heavier, and requires specialized tools for installation |

| Residential (low-pressure systems) | Our Base: Plastic (PVC, ISO 1167) | Lightweight, cost-effective, and easy to install (tool-free) | Limited to ≤60°C and resists only mild chemicals (e.g., acids) | |

| Moderate Industrial (chemical plants) | Our Advanced: Fiberglass (ASTM D790) ▲ | Resists 50+ chemicals (ASTM D543), ▲ temperature tolerance (up to 80°C) | Slightly higher cost than plastic; requires careful handling for installation | |

| Connection Method | Industrial (critical sealing) | Industry Standard: Threaded (ANSI B1.20.1) | Secure seal for high-pressure applications (200 PSI+) | Requires threading tools and time-consuming installation |

| Residential (DIY projects) | Our Base: Flange (ISO 10432) | Tool-free installation, ideal for low-pressure (≤150 PSI) | Lower pressure rating and less secure under vibration | |

| Moderate Industrial (balanced needs) | Our Advanced: Press-Fit (ISO 10432 ▲) | ▲ 30% stronger seal vs Base (180 PSI), quick installation | Moderate cost increase; requires alignment during installation | |

| Pressure Resistance | High-pressure pipelines | Industry Standard: 200 PSI (ASTM F1921) | Handles extreme pressures in industrial systems | Heavyweight material and high cost |

| Residential/commercial plumbing | Our Base: 150 PSI (ASTM F1921) | Lightweight and cost-effective for standard systems | Not suitable for high-pressure industrial applications | |

| Moderate-pressure systems (e.g., HVAC) | Our Advanced: 180 PSI (ASTM F1921 ▲) | ▲ 20% higher pressure tolerance than Base, durable for mid-range systems | Moderate cost vs Base; requires inspection for optimal seal | |

| Chemical Resistance | Harsh chemical environments | Industry Standard: Resists 100+ chemicals (ASTM D543) | Withstands aggressive chemicals (e.g., solvents, acids, bases) | Heavyweight and expensive |

| Mild chemical exposure (e.g., water) | Our Base: Resists 20+ chemicals (ASTM D543) | Cost-effective for non-corrosive or mildly corrosive fluids | Fails under strong acids/bases or solvents | |

| Moderate chemical exposure (e.g., food) | Our Advanced: Resists 50+ chemicals (ASTM D543 ▲) | ▲ 30% broader chemical resistance than Base, food-safe (FDA-compliant) | Higher cost than Base; requires testing for specific chemicals | |

| Temperature Tolerance | High-temperature systems (e.g., boilers) | Industry Standard: Up to 200°C (ISO 178) | Operates in extreme heat (e.g., industrial ovens) | Heavyweight and requires heat-resistant coatings |

| Standard-temperature systems | Our Base: Up to 60°C (ISO 178) | Lightweight and ideal for ambient or slightly warm environments | Fails in temperatures exceeding 60°C | |

| Moderate-temperature systems (e.g., labs) | Our Advanced: Up to 80°C (ISO 178 ▲) | ▲ 20°C higher tolerance than Base, suitable for lab equipment | Moderate cost increase; avoid extreme heat/cold | |

| Installation Ease | Industrial (time-sensitive projects) | Industry Standard: Requires threading (ISO 10432) | Secure seal for long-term use | Labor-intensive and time-consuming |

| Residential (DIY) | Our Base: Snap-on flange (ISO 10432) | Tool-free installation, ideal for quick fixes | Less secure under pressure/vibration | |

| Moderate Industrial (balanced needs) | Our Advanced: Tool-free press-fit (ISO 10432 ▲) | ▲ 50% faster installation than Base, retains seal under moderate stress | Requires alignment and moderate cost |

⭐⭐⭐⭐⭐ James Carter - Industrial Maintenance Technician

"I’ve been using the Advanced Model of these recessed pipe caps in a chemical processing plant for over six months now, and they’ve held up exceptionally well. The press-fit connection saves so much time during maintenance shutdowns — no tools needed, and the seal remains tight even with vibration from nearby pumps. We’ve had no leakage or cap dislodgement, which was a frequent issue with our old threaded caps."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Emily Tran - Homeowner & DIY Enthusiast

"I bought the Base Model for protecting exposed electrical conduits during our basement remodel. They fit perfectly on all 1/2-inch pipes, and I love how low-profile the recessed design is — nothing sticks out to get bumped. Installation was literally a snap, and they look clean and professional. Only reason I didn’t give five stars is that I wish they came in white to better match our wiring system."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Rafael Mendez - HVAC Project Lead

"We’ve standardized on the Pro Model for all our commercial HVAC installations. The glass-filled nylon holds up to temperature swings in unconditioned spaces, and being able to use either press-fit or threaded connections gives us flexibility across different job sites. We also color-coded them (blue for supply, red for return), which has improved field clarity and reduced errors during commissioning."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Linda Park - Senior Piping Systems Engineer

"For mid-pressure industrial applications, especially in food processing or HVAC, I recommend the Advanced Model with press-fit connection. Its 180 PSI rating and FDA-compliant HDPE material offer an excellent balance of safety, performance, and ease of installation. It outperforms standard plastic caps in both chemical and thermal resistance while remaining cost-effective."

David Liu - Construction Safety & Compliance Advisor

"These caps are a simple but critical component in jobsite safety. By preventing debris and moisture ingress during laydown periods, they reduce future blockages and contamination risks. The flange version is ideal for inspection walks — it's visibly secure and meets OSHA-recommended best practices for temporary conduit protection."

Posted: 5 days ago

"Used these on rooftop solar conduit arrays. UV resistance is real — after 5 months under direct sun, no cracking or fading. Press-fit sealed tight even through heavy rain. Will be buying more for upcoming projects."

Posted: 2 weeks ago

"Needed a quick, hygienic way to cap off unused lines during cleaning cycles. These FDA-compliant caps are perfect — smooth, non-porous, and easy to sanitize. No bacterial buildup observed during inspections."

Posted: 3 weeks ago

"Overall very satisfied with the Advanced Model. Installed on 50+ lines in a manufacturing plant. One or two required slight reseating due to misalignment, but once set, all have stayed secure. Much faster than threading."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.