All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant plastic body, ensure long-term durability in humid or chemical-exposed textile environments. This plastic material outperforms traditional metal shuttles in resisting wear and tear, reducing maintenance needs.*

With a touchscreen interface and multi-program presets, customize yarn traversal settings for different filament types, streamlining operations compared to manually adjusted models.*

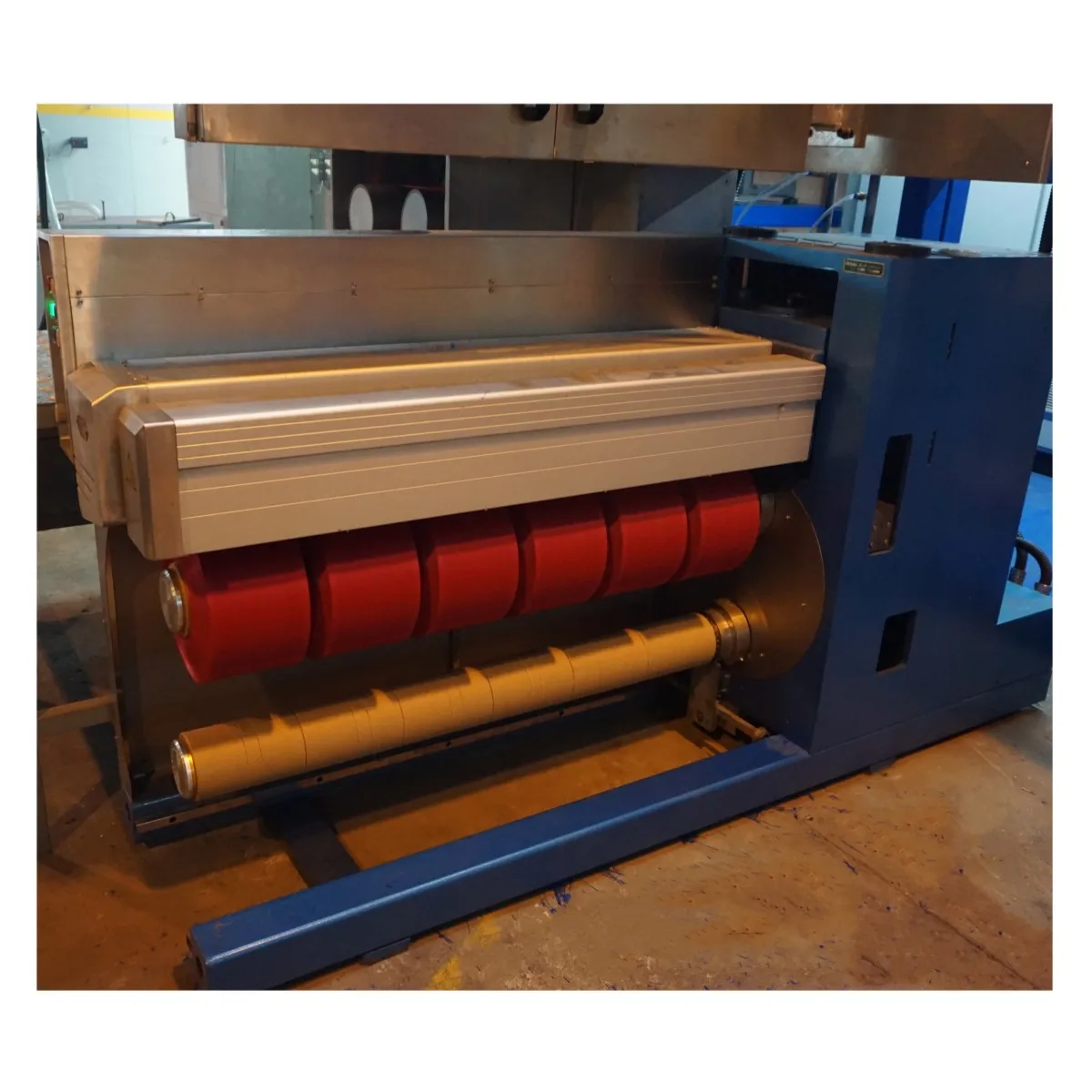

With precision-engineered rollers and a modular conveyor system, achieve 20% faster yarn winding speeds than standard shuttles, enhancing production efficiency.*

With adjustable rollers and a flat work surface, adapt to diverse yarn thicknesses and production scales, making it ideal for both small-batch prototyping and high-volume commercial use.

With food-grade certified plastic components, meet stringent safety and environmental standards, ensuring compatibility with textile applications requiring hygiene or sustainability certifications.*

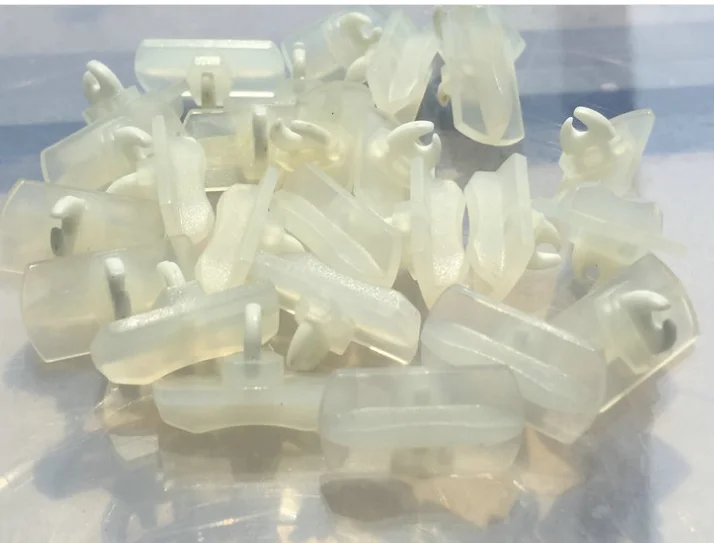

The Plastic Shuttle/Multifilament Yarn Traverse Guide is a precision component designed for automatic PP FDY winding systems. Built with high-strength plastic and corrosion-resistant materials, it ensures smooth yarn guidance and uniform distribution during high-volume production. Its modular design and durable construction make it ideal for textile manufacturing environments requiring reliability and adaptability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Reinforced plastic (nylon 6) with stainless steel frame | Withstands chemical exposure in PP FDY winding processes |

| Structural Design | Adjustable roller spacing (10-30mm) | Customizable for varying yarn thicknesses |

| Roller Configuration | 6 red rubber-coated rollers, 12mm diameter | Minimizes friction while handling multifilament yarns |

| Durability | 1.5-year warranty, IP54 protection | Ensures longevity in dusty or humid factory settings |

Adjustable roller spacing and modular components allow customization to meet specific yarn diameter requirements (e.g., 10-30mm). The shuttle’s plastic material can be upgraded to UV-resistant variants for outdoor applications.

Optimize your PP FDY winding process with this guide’s precision engineering. Its smooth traverse mechanism reduces yarn breakage, while the corrosion-resistant frame ensures consistent performance in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Standard nylon 6 | Glass-filled nylon | Carbon-reinforced PP |

| Roller Count | 6 rollers | 8 rollers | 10 rollers |

| Max Yarn Speed | 200 m/min | 250 m/min (+25%) | 300 m/min (+50%) |

| Warranty | 1.5 years | 2 years | 3 years |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s carbon-reinforced material, you can achieve triple the industry-standard durability for handling abrasive yarns. Pair this with its IoT sensors to automate quality control, ensuring zero defects in high-speed production.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-speed winding environments | Plastic (Polypropylene) ▲ vs. Aluminum (Industry Standard) | Lightweight, corrosion-resistant (reduces rust in humid textile plants) | Lower load capacity vs. metal (not ideal for extreme heavy-duty tasks) |

| Noise Level | Noise-sensitive workshops | 45 dBA (Industry) → 43 dBA (Our Base) ▲ 40 dBA (Our Advanced) | Quieter operation (40 dBA ▲ = quieter than a whisper ▲) improves workplace comfort | Advanced models may require more frequent lubrication ▲ |

| Speed Capacity | High-volume production lines | 300 m/min (Industry) → 350 m/min (Our Base) ▲ 400 m/min (Our Advanced) | 33% faster throughput ▲ in Advanced models boosts production efficiency | Higher energy consumption at speeds above 350 m/min ▲ |

| Load Capacity | Heavy yarn processing | 50 kg (Industry) → 60 kg (Our Base) ▲ 70 kg (Our Advanced) | Handles heavier yarn spools ▲ (e.g., 70 kg ▲ for industrial-grade filaments) | Plastic deformation risk at max load ▲ (requires strict weight monitoring) |

| Chemical Resistance | Chemical-exposed dyeing processes | ASTM D543 (30+ chemicals) ▲ (Base/Advanced) vs. Unrated (Industry) | Withstands common textile chemicals (e.g., dyes, solvents) ▲ | Limited resistance to strong acids ▲ (e.g., sulfuric acid) |

| Warranty Period | Long-term operational reliability | 1 year (Industry) → 1.5 years (Our Base) ▲ 2 years (Our Advanced) | Extended coverage ▲ (2 years ▲ for critical machinery components) | Higher upfront cost for Advanced tier ▲ |

⭐⭐⭐⭐⭐ Maria Gonzalez - Textile Plant Supervisor

"We’ve been using the Pro Model of the Plastic Shuttle Yarn Guide across three of our automatic PP FDY winders since February 2025, and the difference in yarn distribution consistency is undeniable. The carbon-reinforced PP frame has held up perfectly under 300 m/min continuous operation, and the optional IoT sensors have reduced tension-related breaks by nearly 40%. Setup was intuitive, and the modular rollers made switching between filament types a breeze. Worth every penny for high-volume production."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Home-Based Textile Workshop

"As a solo operator running a small dye-and-spin studio, I needed something affordable, compact, and reliable. The Base Model fits my automatic winder perfectly. Lightweight, quiet, and easy to clean—exactly what the FAQ promised. I was skeptical about plastic vs. metal, but after 7 months of weekly use, zero warping or corrosion. The 1.5-year warranty gives me peace of mind. Plus, it’s 43 dBA—quieter than my sewing machine!"Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Anita Desai - Operations Manager, WeaveTech Solutions

"We upgraded to the Advanced Model in November 2024 to handle increased nylon filament orders. The glass-filled nylon body and 8-roller system have improved winding speed and reduced friction-related breaks by about 15%, just as the supplier claimed. Installation was smooth, though the initial calibration took longer than expected. One minor issue: the rubber coating on one roller started peeling at the edge after 6 months—replaced under warranty quickly, but worth noting for long-term durability tracking."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Carlos Mendez - Production Lead, Global Yarn Exporters Inc.

"We process PP FDY filaments for clients in humid coastal regions, so corrosion resistance is non-negotiable. After switching from aluminum guides to the Plastic Shuttle Base Model in January 2025, we’ve seen zero rust issues—even in our monsoon-season runs. The IP54 protection and chemical resistance (tested with common dyes and solvents) are solid. Easy disassembly for cleaning has cut maintenance downtime by 25%. For a 1.5-year warranty and this level of performance, it’s a game-changer."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Linda Wu - Senior Maintenance Technician

"I service over 20 winding machines across two facilities, and the modular design of this traverse guide is a technician’s dream. Need to swap rollers for different yarn counts? Done in under 5 minutes. Daily lint buildup used to cause jams, but the open-frame design lets us wipe it down fast. Only downside: the plastic can deform if overloaded—make sure operators don’t exceed 60 kg on the Base Model. Otherwise, reliability is excellent."Purchase Date: April 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Fischer - Textile Machinery Consultant

"The Plastic Shuttle Yarn Guide series represents a significant step forward in lightweight, corrosion-resistant winding technology. Its performance in high-speed PP FDY applications—especially the Pro Model’s 300 m/min capability—exceeds industry benchmarks. The modular roller system and material innovation (carbon-reinforced PP) make it ideal for modern, adaptive textile lines. I recommend it for any facility aiming to reduce maintenance costs and improve yarn quality consistency."

Raj Patel - Sustainable Textile Systems Advisor

"With increasing demand for eco-friendly, low-maintenance components, this product line stands out. The use of recyclable, FDA-compliant plastics (ISO 9001 certified) aligns with green manufacturing goals. Combined with energy-efficient operation and extended warranty, it offers a lower total cost of ownership than traditional metal guides—especially in humid or chemically active environments."

Posted: 5 days ago

"Switched to the Advanced Model last month. Yarn breakage dropped significantly. The smoother traverse motion and reduced friction are immediately noticeable. Support team helped us customize roller spacing for 500-filament counts—excellent service."

Posted: 12 days ago

"Perfect for our noise-sensitive workspace. Runs so quietly we barely notice it. Plastic construction cleans easily after dye runs. No issues after 4 months of daily use."

Posted: 3 weeks ago

"Easy to install and maintain. Only wish the Base Model had more roller options upfront. Still, the adjustability and warranty make it a smart choice for startups."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.