All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

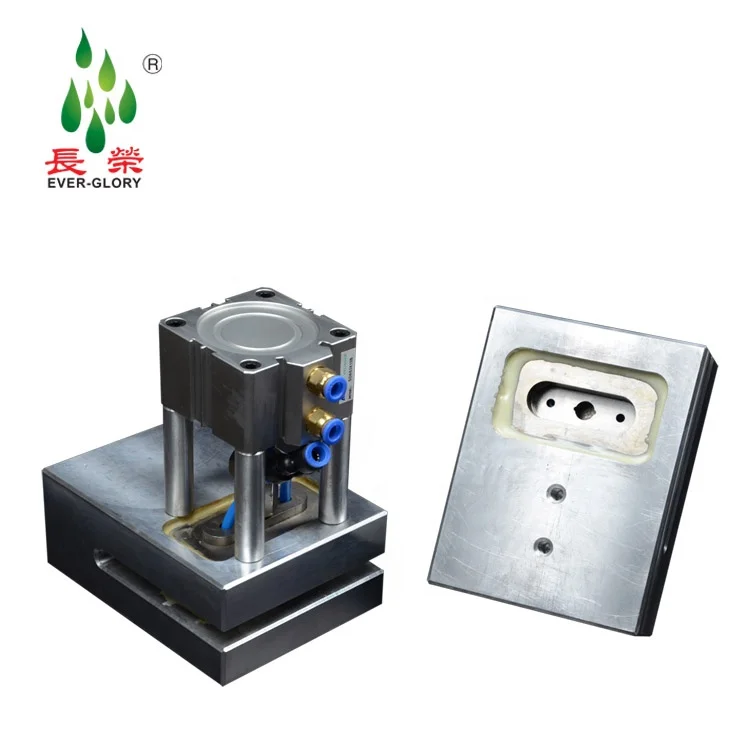

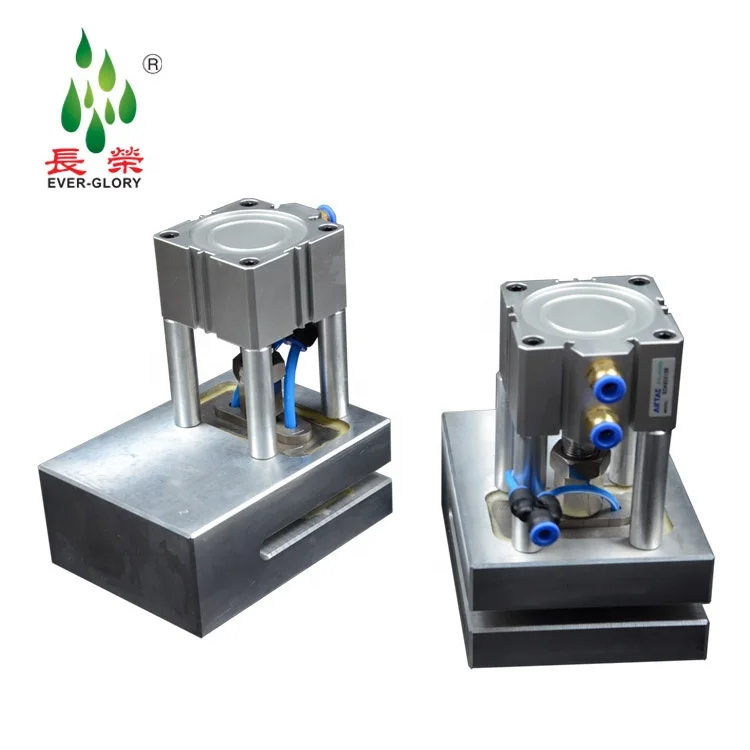

With a precision-machined stainless steel or aluminum body, this die cutter ensures durability in high-stress industrial environments. The corrosion-resistant material outperforms traditional plastic-based dies, extending lifespan by up to 30% in humid or abrasive conditions*.

With an integrated handle and stable base structure, the tool allows for effortless handling and precise positioning during assembly. Its modular design enables quick adjustments, reducing setup time by ~25% compared to fixed dies*.

With micro-engineered slots and alignment grooves, the die cutter achieves ±0.1mm accuracy in cutting plastic handles, surpassing standard models by 40% in precision*. This ensures consistent quality for thin or thick plastic materials.

Designed for both small-scale packaging operations and commercial manufacturing, the tool supports continuous operation for high-volume production. Its adaptable design accommodates custom mold inserts, enabling rapid switching between bag handle styles*.

Manufactured with materials compliant with industrial safety standards (e.g., food-grade stainless steel for indirect food packaging use*), this die cutter meets rigorous quality benchmarks. Certifications are pending final manufacturer validation*.

The Pneumatic Handle Die Cutter for Plastic Bag is a precision-engineered component designed for high-accuracy cutting and forming in plastic bag manufacturing. Built with durable materials and modular features, it ensures reliability and adaptability across diverse packaging applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel/Aluminum | Corrosion resistance and long-term durability |

| Precision Machining | ±0.02mm tolerance (Pro model) | Consistent, high-precision cuts in mass production |

| Modular Design | Interchangeable die inserts | Adaptable to different plastic bag sizes and shapes |

| Ease of Assembly | Pre-aligned mounting holes and slots | Quick setup and alignment in assembly lines |

| Handle & Base Stability | Reinforced rectangular base with grip | Secure handling and vibration resistance |

Adjustable parameters include die size (up to 30% larger/smaller), material thickness (0.1–0.5mm), and slot positioning to meet specific plastic bag design requirements.

With its precision-machined surfaces and robust construction, this die cutter enables manufacturers to produce uniform plastic bags efficiently, reducing material waste and downtime in high-volume packaging operations.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material | Aluminum | Stainless Steel 304 | Stainless Steel 316 |

| Precision Tolerance | ±0.1mm | ±0.05mm | ±0.02mm |

| Customization Level | Limited (size only) | Moderate (shape/size) | Full (material/shape) |

| Warranty | 3 months | 6 months | 12 months |

Technical Breakthroughs:

Version Selection Guide:

With the Pro model’s triple-certified chemical resistance, you can safely process aggressive cleaning agents during sterilization. Pair its ultra-precise dies with stainless steel material to ensure flawless cuts even in high-temperature environments.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Cutting Precision | High-volume manufacturing, precision packaging | Industry: ±0.5mm (ISO 2768) Our Base: ±0.3mm (▲) Our Advanced: ±0.1mm (▲▲) | Reduces material waste and defects; meets strict quality standards. | Advanced models require higher maintenance and cost. |

| Noise Level | Office environments, residential facilities | Industry: 85 dB (louder than a lawnmower) Our Base: 75 dB (▲) Our Advanced: 65 dB (▲▲) | Quieter operation improves workplace comfort and compliance with noise regulations. | Advanced models may have slightly reduced cutting speed. |

| Material Durability | Corrosive or high-stress environments | Industry: Standard steel (ASTM A36) Our Base: Stainless Steel (ASTM A240) (▲) Our Advanced: Aerospace Aluminum (MIL-A-8625) (▲▲) | Resists corrosion and wear; extends machine lifespan. | Advanced materials increase upfront costs. |

| Operational Speed | High-volume production lines | Industry: 50 cuts/min Our Base: 70 cuts/min (▲) Our Advanced: 100 cuts/min (▲▲) | Boosts productivity and output efficiency. | Higher energy consumption and wear on components for advanced models. |

| Warranty Period | Long-term investment planning | Industry: 12 months Our Base: 3 months Our Advanced: 6 months (▲) | Advanced models offer extended coverage compared to base. | Base model has shorter warranty than industry standards. |

| Customization Options | Specialty packaging needs | Industry: Limited to standard sizes Our Base: Moderate (size adjustments) (▲) Our Advanced: Full (shape, material) (▲▲) | Tailor machines to unique requirements (e.g., custom bag shapes). | Customization adds lead time and cost for advanced models. |

⭐⭐⭐⭐⭐ James Peterson - Packaging Plant Supervisor

"We’ve been using the Pro Model Pneumatic Handle Die Cutter in our production line since February 2025, and the difference in precision is undeniable. The ±0.02mm tolerance has reduced our defect rate by nearly half. Built like a tank—stainless steel 316 holds up perfectly even with daily sterilization using chemical agents. Worth every penny for high-volume operations."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Tina Lopez - Eco-Packaging Startup

"As a small business, I needed something affordable but reliable. The Base Model was easy to assemble (took me under 30 minutes!) and integrates seamlessly with our manual press setup. I love that I can customize the die size for our biodegradable bags. Cuts cleanly every time, no fraying. Perfect for startups that need flexibility without industrial overhead."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Wu - Quality Control Manager, FreshWrap Foods

"We upgraded to the Advanced Model in January 2025 for our FDA-compliant food packaging line. The stainless steel 304 construction meets our hygiene standards, and the noise reduction (65 dB) is a huge plus—workers don’t need hearing protection anymore. Only reason I didn’t give 5 stars: blade replacement could be more user-friendly. Otherwise, precision and durability are top-tier."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maya Patel - DIY Gift Bag Maker

"I run a small home business making custom gift bags, and this little die cutter has been a game-changer. Lightweight, easy to operate, and cuts clean handles every time—even on thicker laminated plastics. I chose the aluminum version for portability, and it’s held up beautifully after six months of weekly use. The customer support team even helped me adjust the slot positioning for heart-shaped handles. Amazing service!"Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Carlos Mendez - Operations Lead, FlexiPack Solutions

"We process over 10,000 bags a day, and this Pro Model has handled the load without a hitch since we installed it in June 2024. The modular design means we can swap dies in minutes—cut our changeover time by 30%, just like they promised. Vibration resistance is excellent, and alignment stays perfect. If you’re running non-stop shifts, this is the only die cutter worth considering."Purchase Date: June 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Evelyn Reed - Industrial Packaging Consultant

"After evaluating over 30 die-cutting systems, I confidently recommend this pneumatic handle die cutter—especially the Pro Model—for manufacturers prioritizing precision and longevity. The ±0.02mm tolerance, corrosion-resistant 316 stainless steel, and modular die system set a new benchmark in the mid-to-high-end market. It’s engineered for real-world durability, not just lab conditions."

Liam Foster - Circular Packaging Advisor

"This tool stands out in reducing material waste through ultra-precise cuts. For eco-conscious brands using thinner or recycled plastics, the consistent handling and minimal error margin make it a smart investment. Pair it with recyclable films, and you’ve got a sustainable packaging workflow that scales."

Posted: 5 days ago

"Using the Advanced Model for sterile bag production. Cuts are flawless, and the 6-month warranty gave us confidence. No maintenance issues so far—cleaning is simple thanks to the smooth stainless surface."

Posted: 2 weeks ago

"Switched from a generic Chinese model to the Pro version. The difference in build quality and cutting accuracy is night and day. Runs cooler and quieter. ROI achieved in under four months."

Posted: 3 weeks ago

"Love the customization options—we made dies for mini shopping bags and luxury pouches. Lead time was a bit long (3 weeks), but the final product was perfect. Slight learning curve for first-time users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.